Armature installation structure

A technology of installation structure and armature, applied in the direction of detailed information of electromagnetic relays, relays, electrical components, etc., can solve the problems of inconvenient assembly, achieve the effect of convenient assembly, fast and convenient assembly process, and sufficient assembly operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

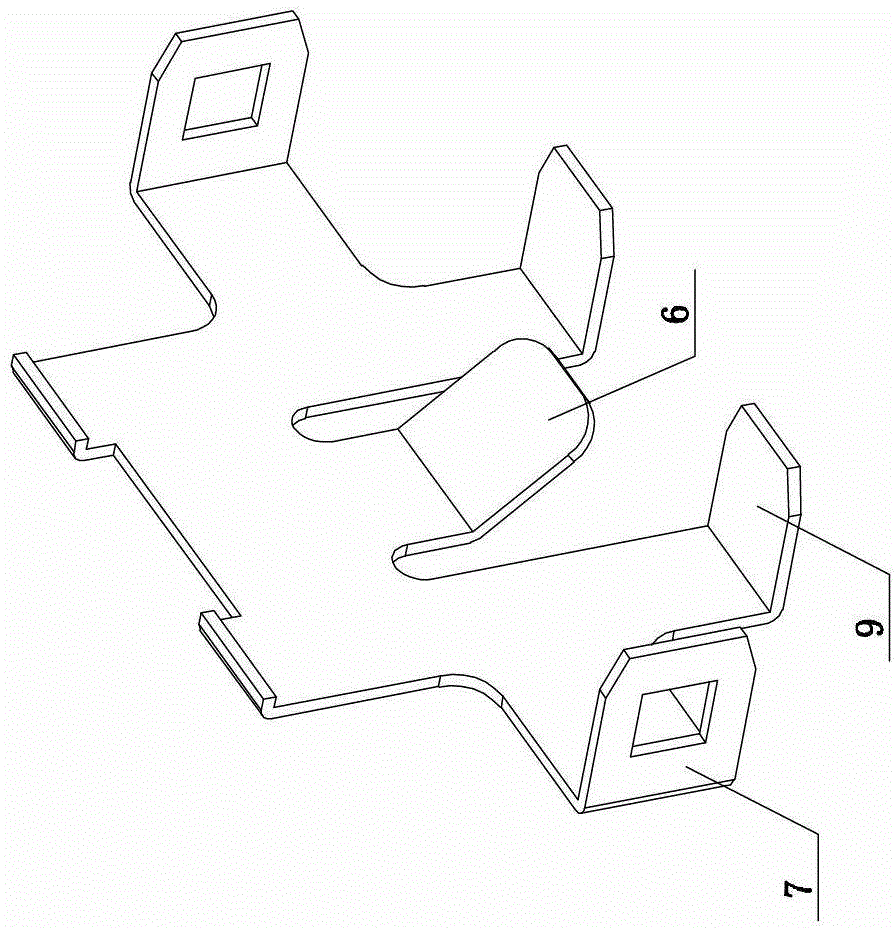

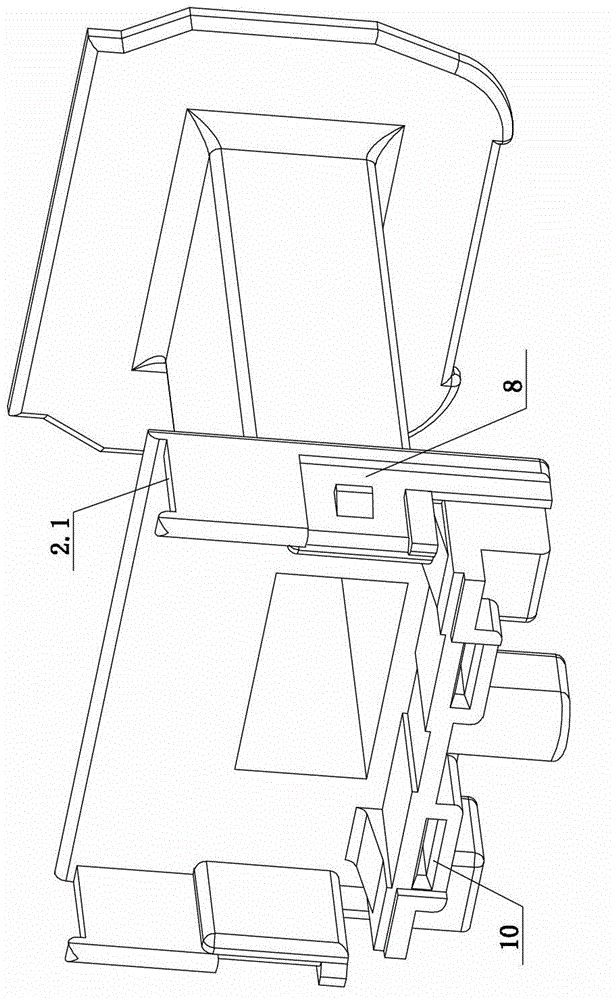

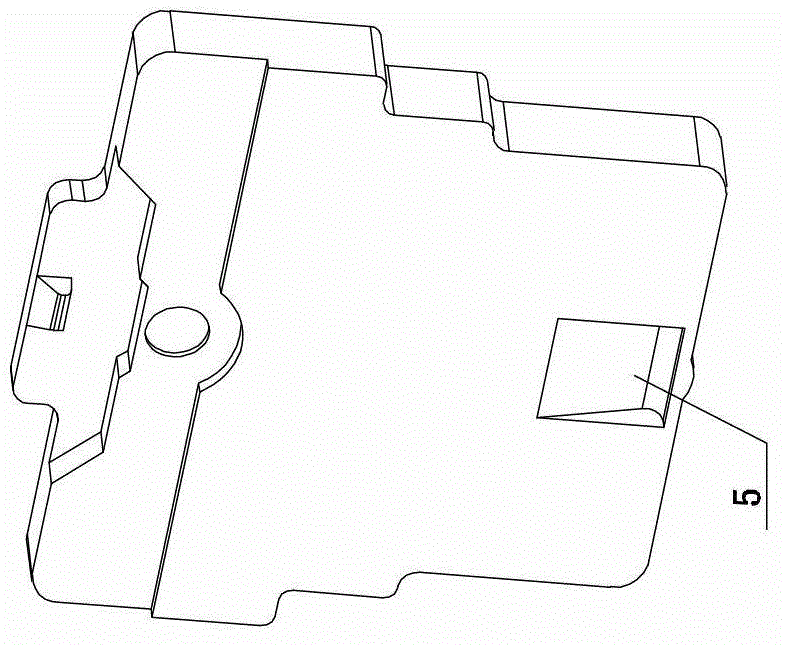

[0017] The armature installation structure of the present invention includes an armature 1, a coil frame 2 and an armature limiter 3, the coil frame 2 is provided with a support portion 2.1 for supporting the armature 1, the armature 1 can move relatively around the support portion 2.1, and the armature limit After the part 3 is connected with the coil frame 2, a space 4 is formed between the armature limiter 3 and the coil frame 2 for the partial insertion of the armature 1, the armature 1 is partially located in the space 4, and the armature 1 is partially facing the armature limiter There is a depression 5 on this surface of 3, and the armature limiter 3 is provided with an elastic limiter 6 that can be partly pushed away by the armature 1 and finally falls into the depression 5, and the depression 5 includes an elastic limiter The two side surfaces constituting the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com