Luminaire assembly

A technology for lighting devices and headlights, applied in signal devices, lighting and heating equipment, transportation and packaging, etc., can solve the problems of short service life, large structure, multi-energy, etc., and achieve extended service life and high service life , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

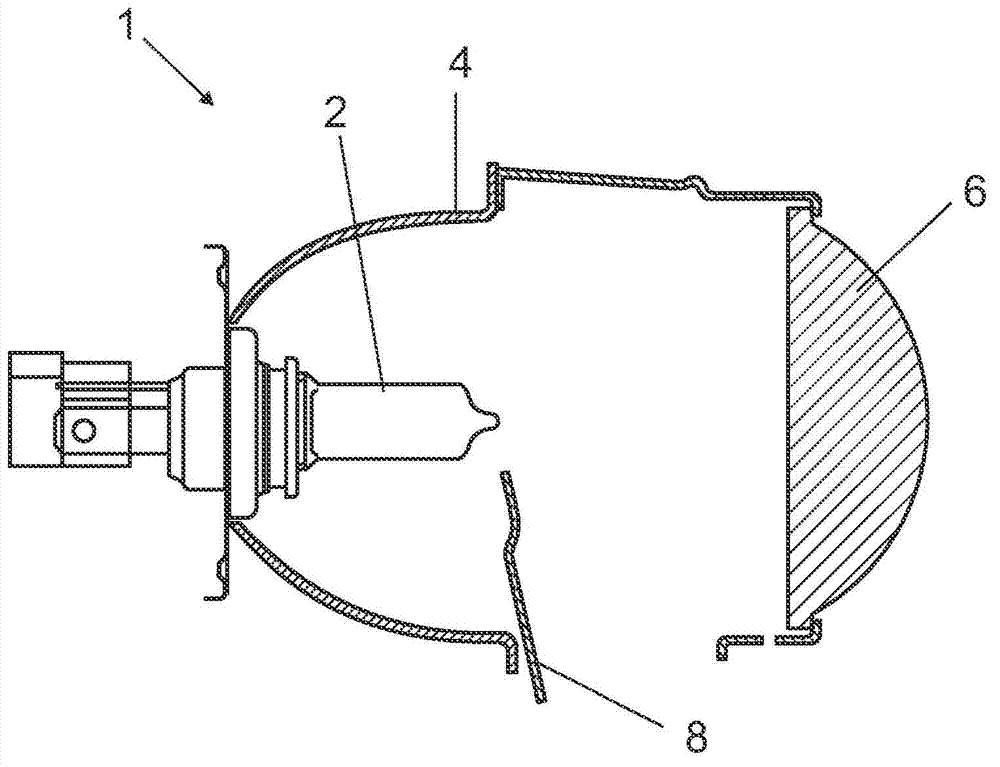

[0019] The single figure shows a very simplified schematic illustration of a lighting device 1 according to an exemplary embodiment. In this case it is a double halogen headlight for motor vehicles. These headlamps produce low and high beams from a single light source. In the shown figures, in this case an H7 halogen incandescent lamp, which is referred to below as lamp 2 . The H7 halogen incandescent lamp has only one filament coil, which is used as a light source for generating the high beam and also as a light source for generating the low beam.

[0020] The lighting device 1 has a reflector 4 surrounding the lamp 2 and a projection lens 6 in the beam path.

[0021] Via a shutter 8 arranged between the projection lens 6 and the lamp 2 , it is possible to switch between the low-beam lighting function and the high-beam lighting function. The low-beam lighting function and the high-beam lighting function therefore differ in that the cross-section of the beam path is larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com