Conveyor system for sheet-shaped elements

A technology for conveying systems and components, which is applied in the field of conveying systems and can solve problems such as distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

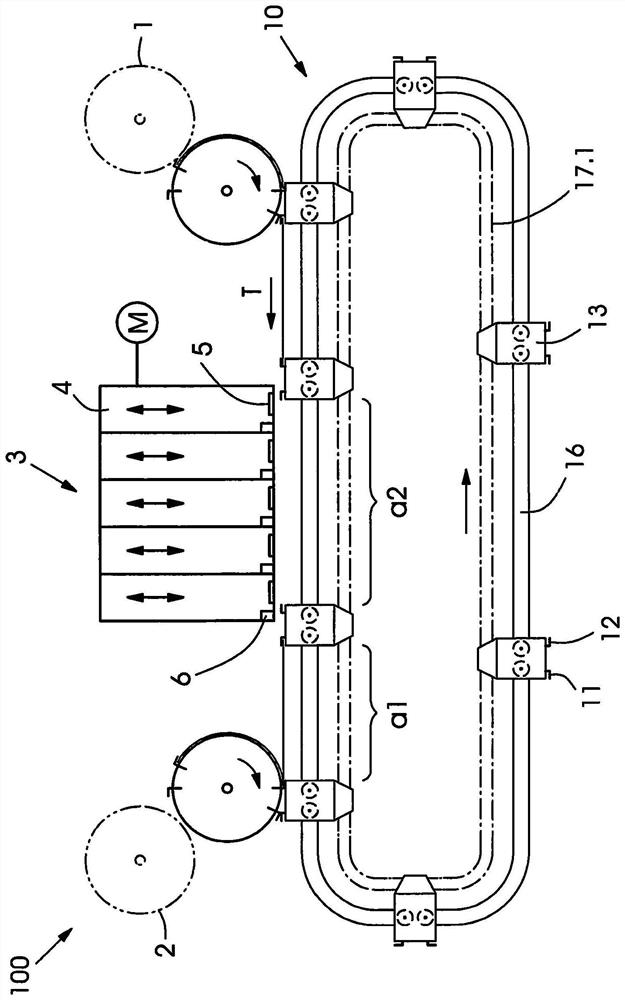

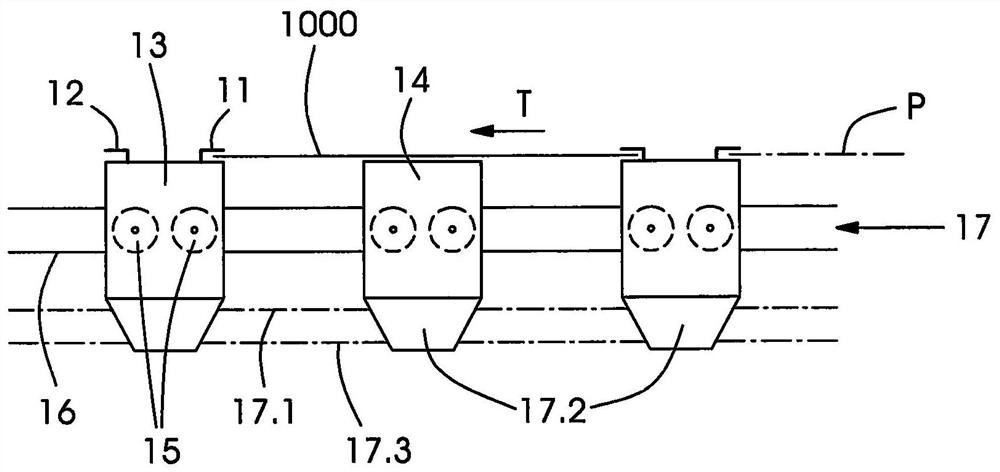

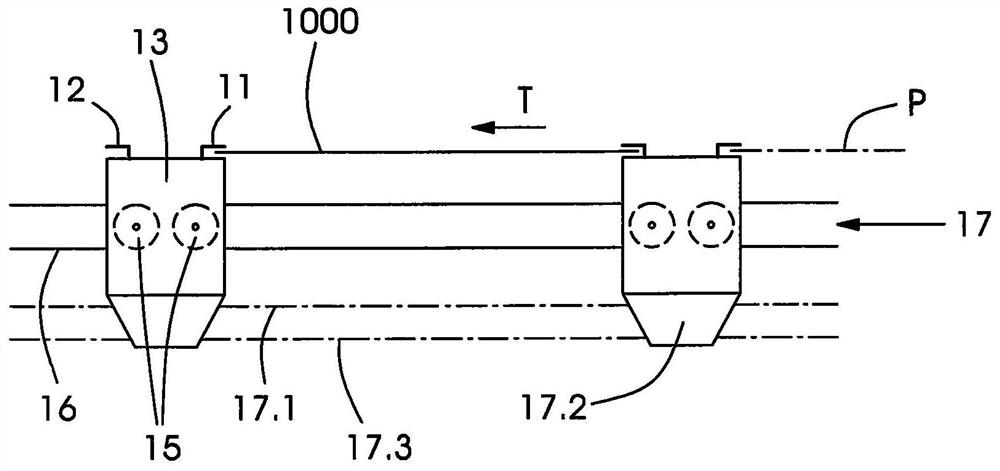

[0022] figure 1 A manufacturing system 100 for processing a sheet-shaped element 1000 is shown. Production system 100 has a sheet supply device 1 , a conveyor system 10 which moves sheet-shaped elements 1000 under processing station 3 , and sheet discharge device 2 . The processing station 3 is designed as a printing station, ie a digital printing station, which, as a processing tool 4 , has a plurality of printing heads which are provided with nozzle plates 5 at their lower ends. The conveyor system 10 has a plurality of carriages 13 with gripper systems, which are moved along guide rails 16 by linear drives 17 . The traveling vehicles 13 can be adjusted individually with respect to their position and speed. The respective sheet-shaped element 1000 is gripped and held at its front edge and at its rear edge by the gripper systems 11 , 12 of the traveling vehicle 13 . The respective sheet-shaped element 1000 should lie substantially on one plane during its transport along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com