Batch annealing interstitial-free (IF) steel and production method thereof

A bell annealing and production method technology, applied in the field of steel rolling, can solve the problem of poor resistance to secondary processing brittleness, achieve the effect of improving the distribution of grain boundaries and improving the performance of secondary processing brittle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

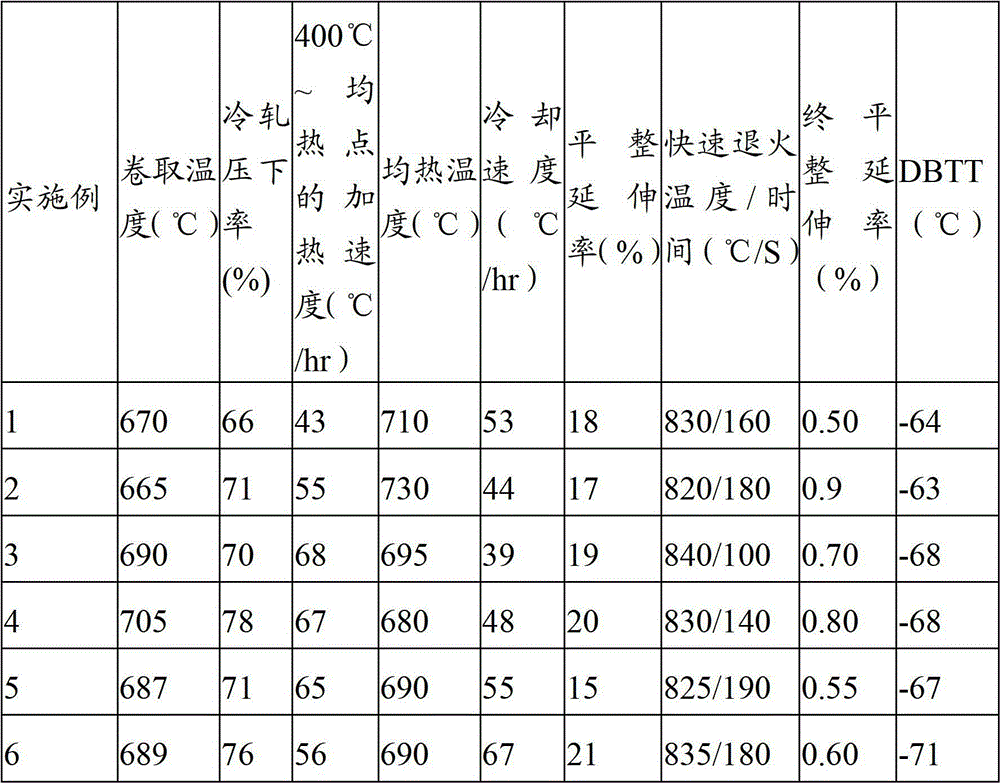

Examples

Embodiment Construction

[0025] The object of the present invention is to provide a method for producing bell annealed IF steel with excellent secondary processing brittleness, through appropriate composition design, and adopting the process optimization method of strain recrystallization after the bell is retreated, the quality of bell annealed IF steel can be improved. The distribution of grain boundaries can reduce the ductile-brittle transition temperature (DBTT) of bell-annealed IF steel to below -60°C, thereby improving the secondary processing brittleness resistance of bell-annealed IF steel.

[0026] In order to achieve the above purpose, the present invention provides a bell-type annealed IF steel, the mass percentage of its chemical composition is: C: 0.0005~0.0035, Si≤0.03, Mn: 0.05~0.30, P≤0.008, S≤0.012, N≤ 0.004, Al: 0.02~0.07, Ti: 0.04~0.09, Nb: 0.003~0.015, B: 0.0003~0.0020 and the balance is Fe and other unavoidable trace elements.

[0027] Among them, C is a strengthening element. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com