Preparation method of high-reaming property high-tensile steel

A high-strength steel and performance technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve problems such as inability to meet deep drawing performance, reduced hole expansion ratio, and inability to achieve ideal comprehensive performance, and improve grain boundary distribution. Condition, improvement of deep drawing performance, effect of high comprehensive service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

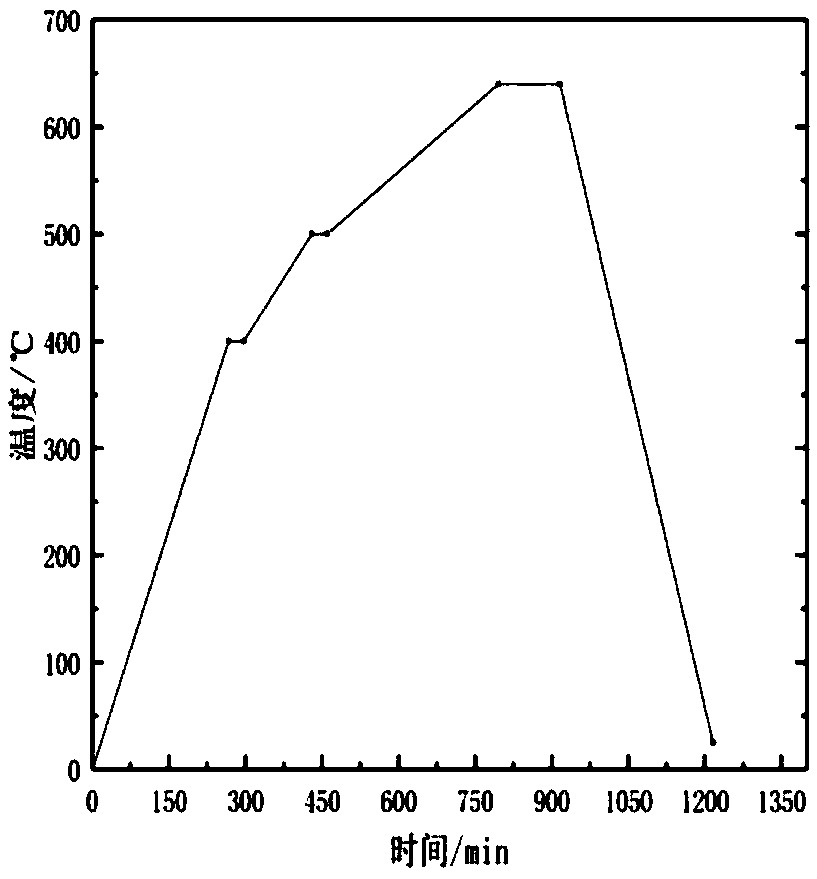

[0041] Example 1: According to the setting of the annealing model, the chemical composition (mass percentage) of a low-alloy high-strength steel cold-rolled plate with a thickness of 1mm is C: 0.08%, Si: 0.2%, Mn: 1.2%, S: ≤ 0.01% , P: ≤ 0.02%, Als: 0.04%, Ca: 0.005%, the balance is Fe and unavoidable impurities. Heat the cold-rolled sheet to 400°C at a rate of 100°C / h, then keep it warm for 30 minutes, then heat it to 500°C at a rate of 50°C / h, keep it warm for 30 minutes, and continue to heat it at a heating rate of 30°C / h Raise the temperature to 660°C, keep it warm for 120min, and then slowly cool to room temperature.

Embodiment 2

[0042] Example 2: According to the setting of the annealing model, the chemical composition (mass percentage) of a low-alloy high-strength steel cold-rolled plate with a thickness of 1mm is C: 0.08%, Si: 0.2%, Mn: 1.2%, S: ≤ 0.01% , P: ≤0.02%, Als: 0.04%, Ca: 0.005%, and the balance is Fe and unavoidable impurities. Heat the low-alloy high-strength steel cold-rolled plate to 400°C at a rate of 90°C / h, then heat it for 30 minutes, then heat it to 500°C at a rate of 45°C / h, continue to hold it for 30 minutes, and continue to heat it at 25°C / h The heating rate was raised to 640°C, kept for 120 minutes, and then slowly cooled to room temperature.

Embodiment 3

[0043] Example 3: According to the setting of the annealing model, the chemical composition (mass percentage) of a low-alloy high-strength steel cold-rolled plate with a thickness of 1mm is C: 0.08%, Si: 0.2%, Mn: 1.2%, S: ≤ 0.01% , P: ≤0.02%, Als: 0.04%, Ca: 0.005%, and the balance is Fe and unavoidable impurities. Heat the low-alloy high-strength steel cold-rolled plate to 400°C at a rate of 80°C / h, then heat it for 30 minutes, then heat it to 500°C at a rate of 40°C / h, continue to hold it for 30 minutes, and continue to heat it at 25°C / h The heating rate was raised to 620°C, kept for 120 minutes, and then slowly cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com