Production method of steel hot-rolled steel strip with yield of 460 MPa for cold stamping axle housing

A production method and cold stamping technology are applied in the field of production of hot-rolled steel strips for yielding 460MPa cold-stamped axle housings, which can solve the problem of low strength level, unstable steel coil passing performance, and difficulty in meeting the fatigue of the axle bench test. cycle and other issues to achieve the effect of high hole expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

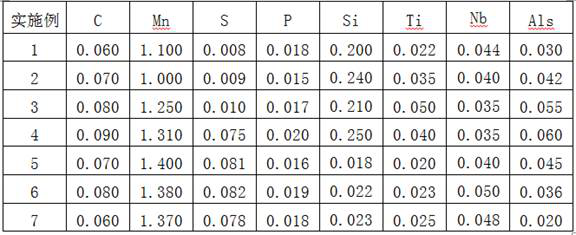

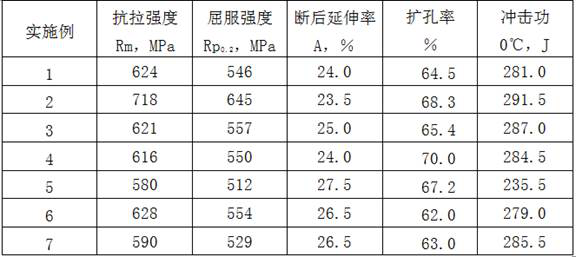

[0022] In this embodiment, the specification of the hot-rolled steel strip for the yield 460MPa cold stamping axle housing is 9.0mm. The chemical composition and mass percentage of the hot-rolled steel strip are shown in Table 1. Billet continuous casting, heating, rough rolling, finish rolling, cooling and coiling process, the specific process steps are as follows:

[0023] (1) Converter smelting process: molten iron and steel scrap are added in converter smelting, the total charge is 105t; the carbon at the end point of converter smelting is 0.020%, the number of supplementary blowing is 1 time, the standing time at the end point is 140s, the temperature at the end point of converter smelting is 1660°C, and the tapping method is double Gear (slide block slag + slag block mark) to reduce the amount of slag; blowing is carried out by high-strength supplementary blowing method, and post-stirring operation is adopted before the final tapping;

[0024] (2) Refining process of LF ...

Embodiment 2

[0033] In this embodiment, the specification of the hot-rolled steel strip for the yield 460MPa cold stamping axle housing is 10.0mm. The chemical composition and mass percentage of the hot-rolled steel strip are shown in Table 1. Billet continuous casting, heating, rough rolling, finish rolling, cooling and coiling process, the specific process steps are as follows:

[0034] (1) Converter smelting process: molten iron and steel scrap are added in converter smelting, with a total charge of 110t; the carbon at the end point of converter smelting is 0.040%, the number of supplementary blowing is 1 time, the resting time at the end point is 160s, the temperature at the end point of converter smelting is 1680°C, and the tapping method is double Gear (slide block slag + slag block mark) to reduce the amount of slag; blowing is carried out by high-strength supplementary blowing method, and post-stirring operation is adopted before the final tapping;

[0035] (2) Refining process of ...

Embodiment 3

[0044] In this example, the specification of the hot-rolled steel strip for yielding 460MPa cold stamping axle housing is 10.5mm. The chemical composition and mass percentage of the hot-rolled steel strip are shown in Table 1. The production methods include converter smelting, LF furnace refining, plate Billet continuous casting, heating, rough rolling, finish rolling, cooling and coiling process, the specific process steps are as follows:

[0045] (1) Converter smelting process: molten iron and steel scrap are added in converter smelting, the total charge is 105t; the carbon at the end point of converter smelting is 0.030%, the number of supplementary blowing is 1 time, the standing time at the end point is 160s, the temperature at the end point of converter smelting is 1680°C, and the tapping method is double Gear (slide block slag + slag block mark) to reduce the amount of slag; blowing is carried out by high-strength supplementary blowing method, and post-stirring operation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com