Multifunctional automatic tabouret of computerized embroidery machine

A full-featured, embroidery machine technology, applied in the field of computerized embroidery machines, can solve problems such as inability to adjust, dislocation of flower shapes, troubles, etc., and achieve the effect of simple replacement procedures and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

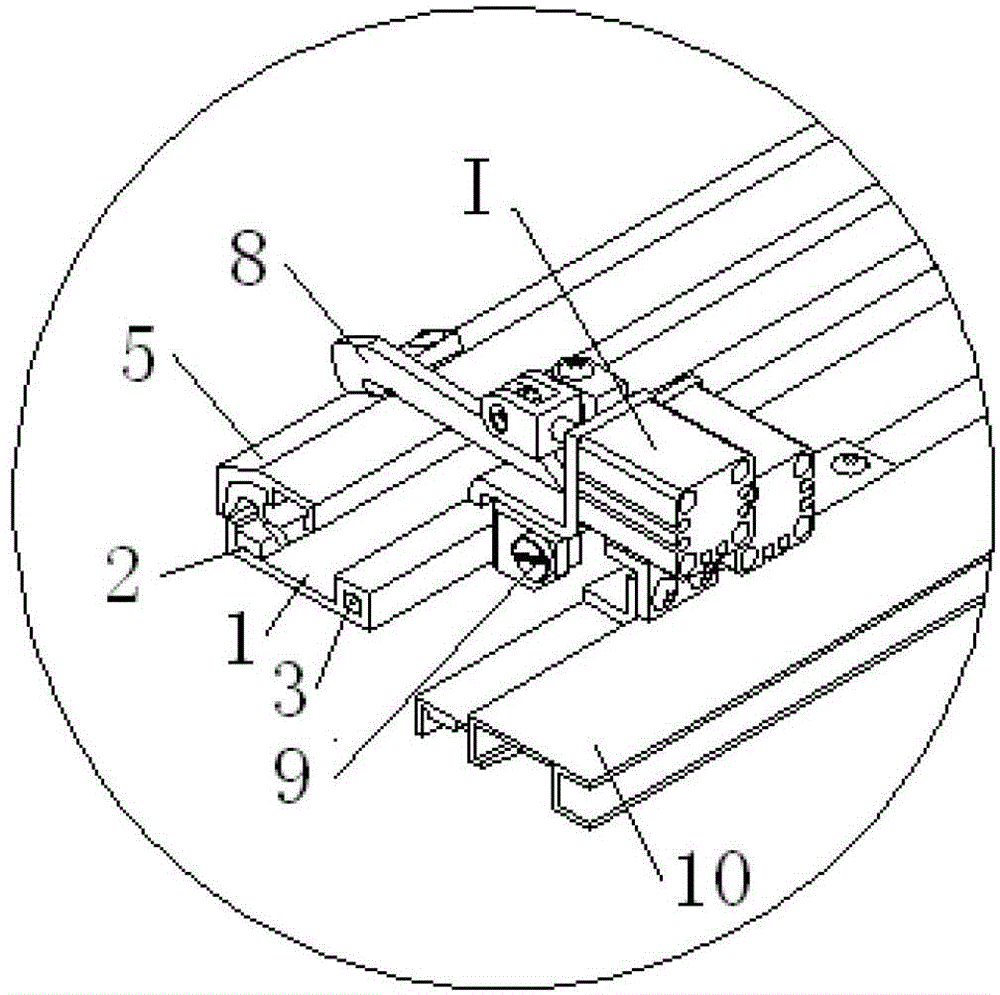

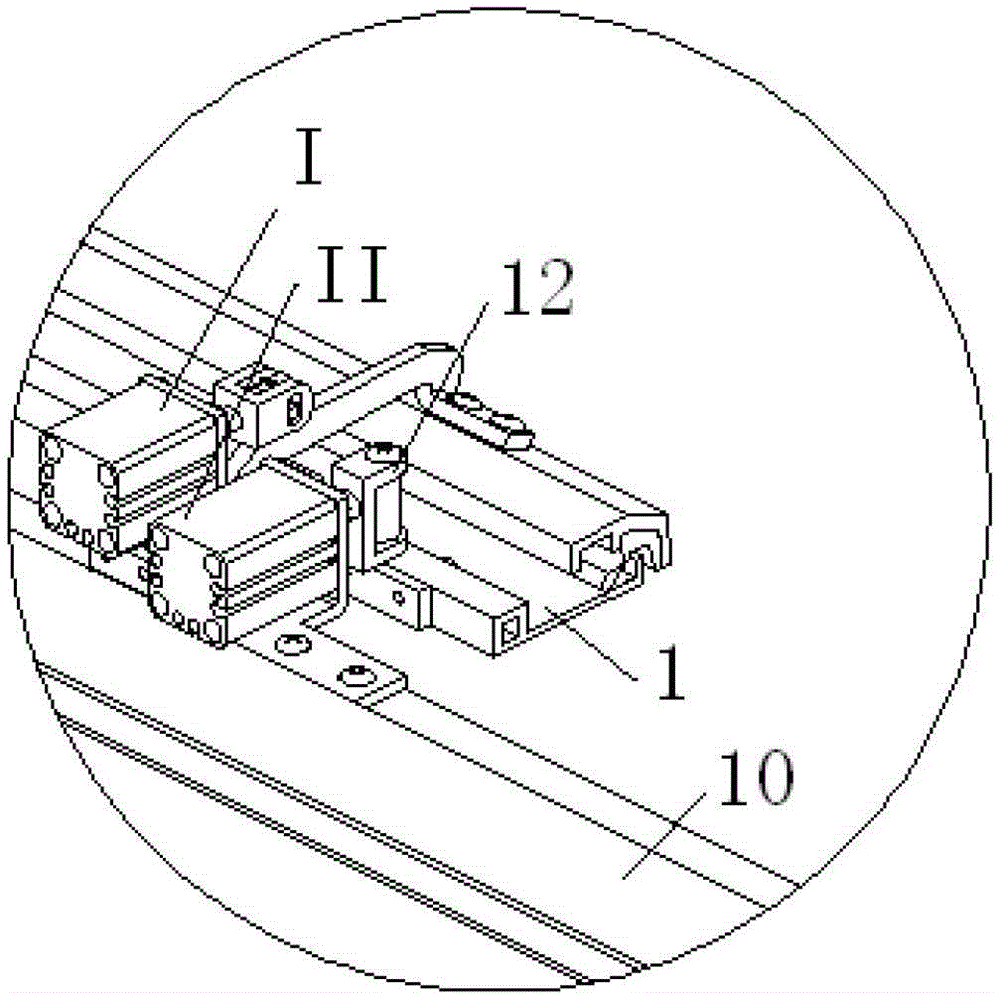

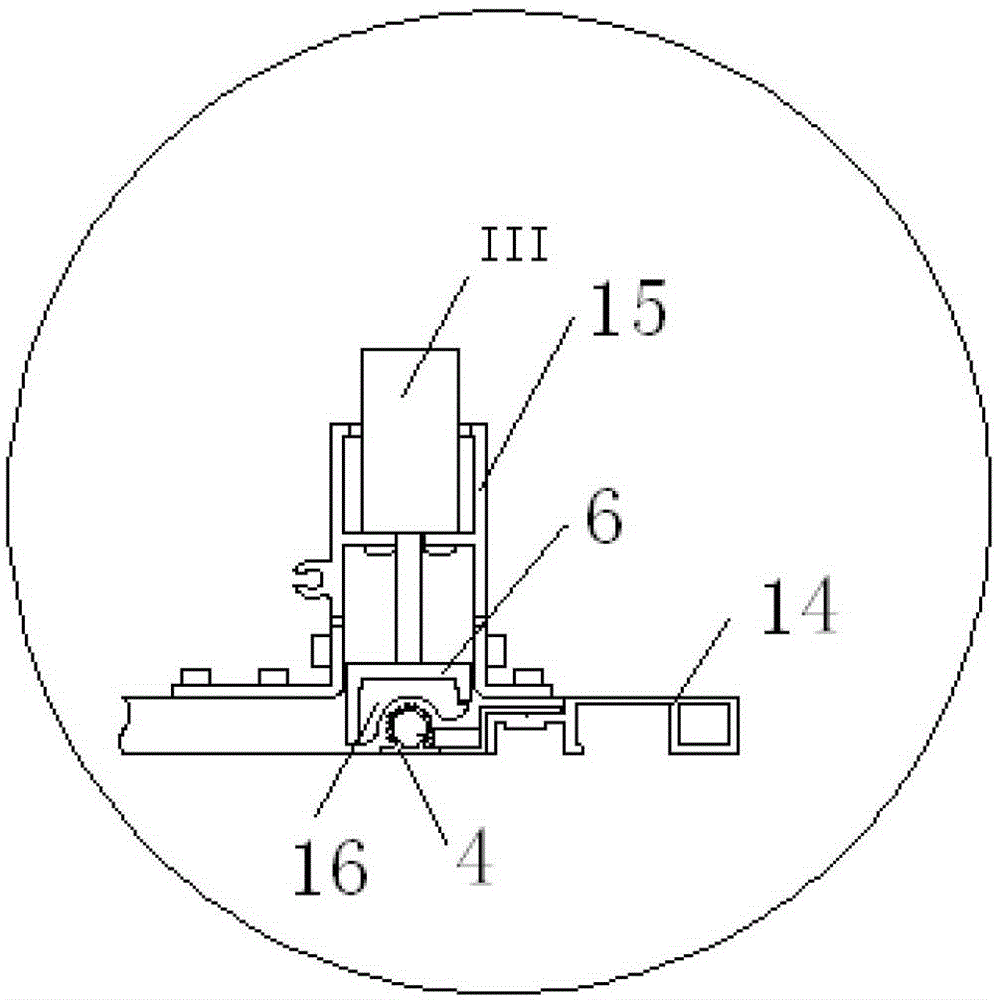

[0025] Below, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

[0026] The full-function automatic embroidery frame of the computerized embroidery machine of the present invention includes: the embroidery frame body, the left and right beams that pull the embroidery frame body to move in the X direction on the horizontal plane, the front beams that move in the Y direction, the middle beam and the driving mechanism, and the X-direction cloth tightening device , X-direction fabric tensioning device and Y-direction fabric tightening device. The body of the embroidery frame is rectangular, and the surrounding borders are called side strips. The embroidery cloth is laid flat on the embroidery frame and clamped, and placed under the head of the embroidery machine. and Y-direction plane movement, the embroidery frame body has a certain distance from the front beam, rear beam and left and right beams, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com