Brake shoe structure used for brakes of three-wheeled vehicles and other vehicles

A three-wheeled vehicle and brake shoe technology, applied in the field of brake shoes, can solve the problems of wasting friction lining materials and high cost of brake shoes, and achieve the effects of material saving, low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

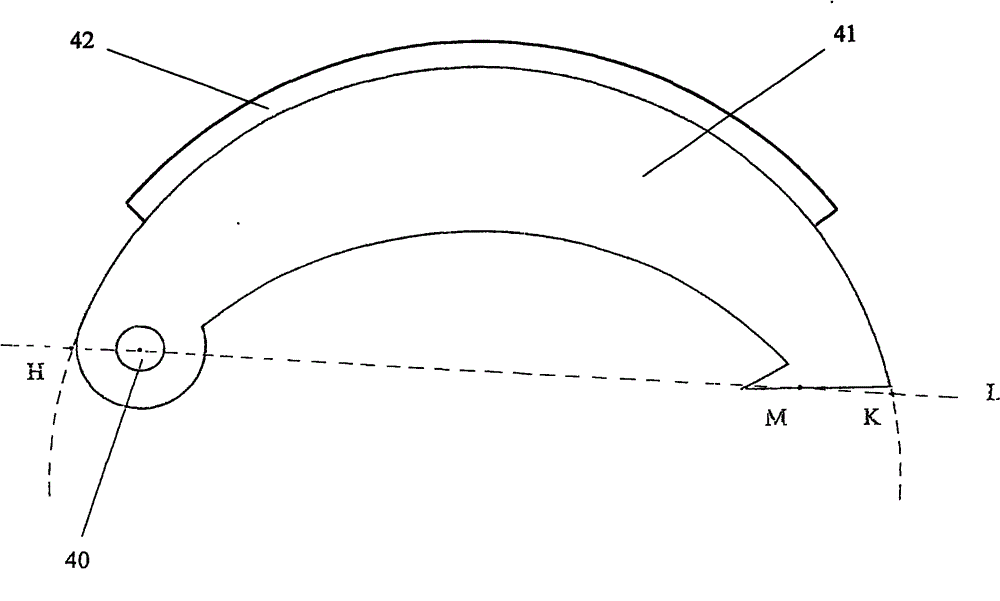

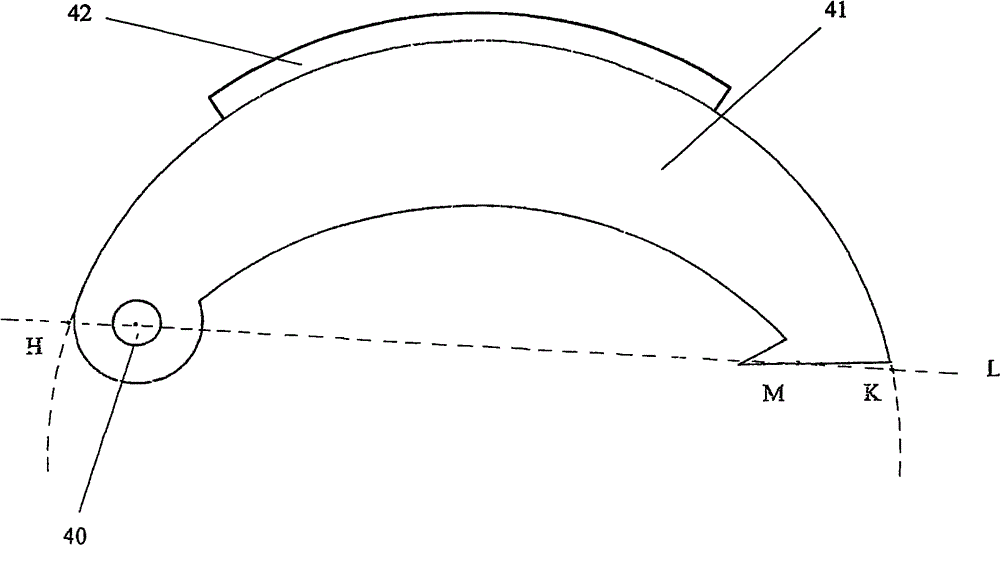

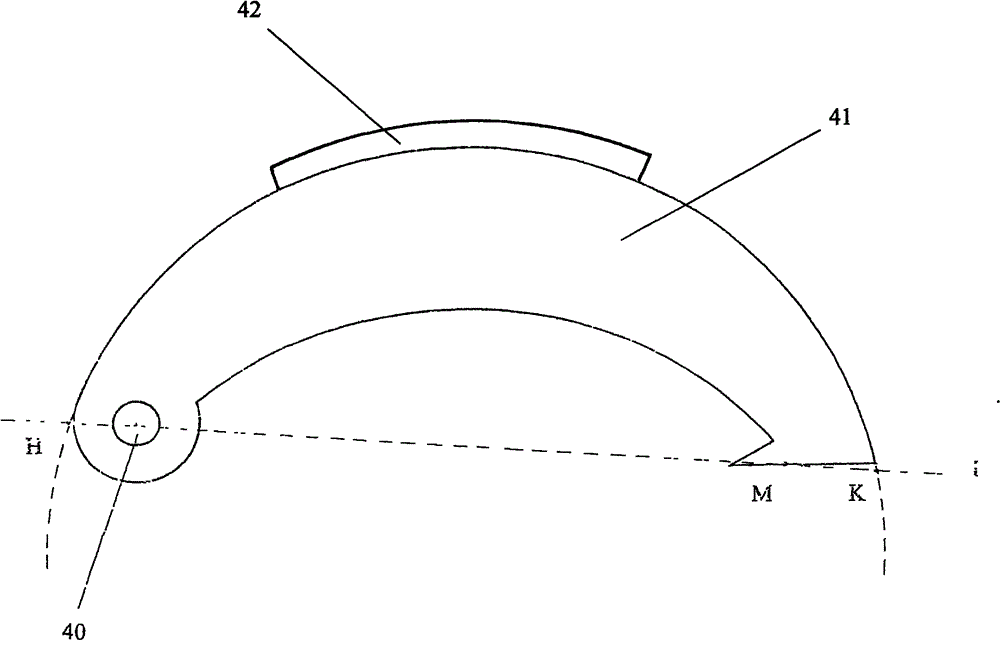

[0028] figure 2 A first embodiment of the brake shoe construction of the present invention for use in brakes of three-wheeled vehicles and other vehicles is shown. According to the figure, it includes a metal shoe 41 and a friction plate 42, and the metal shoe 41 and the friction plate 42 are riveted. The arc length of the friction plate in this embodiment is 14.9 centimeters, the width of the friction plate is 3.5 centimeters, 14.9×3.5=52.15 square centimeters, the arc area of the friction plate is 52.15 square centimeters; the arc length of the metal shoe is taken as 29.8 cm, the thickness of the metal shoe is 3.5 cm, 29.8×3.5=104.3 square centimeters, the arc area of the metal shoe is: 104.3 square centimeters; The arc area of the friction plate accounts for 50% of the arc area of the metal shoe.

[0029] Compared with the prior art, this embodiment is essentially that the arc area of the friction plate is smaller than the arc area of the metal shoe, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com