Lead-melting-free cutter adjusting device for granulator

An adjustment device and granulator technology, which is applied in the field of lead ingot granulator, can solve the problems such as the inability to adjust the verticality of the cutter, and achieve the effects of convenient adjustment and positioning, cost reduction, and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

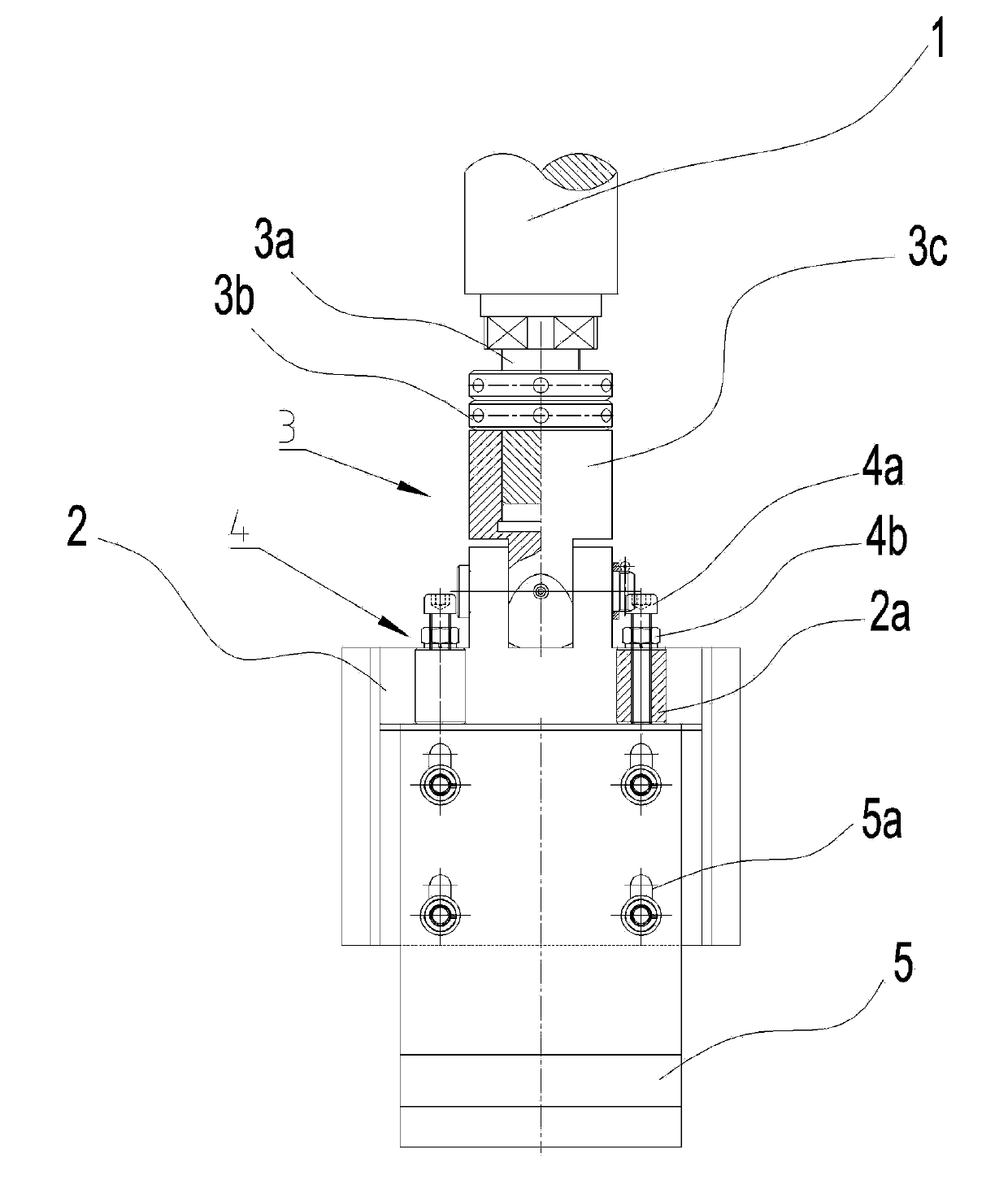

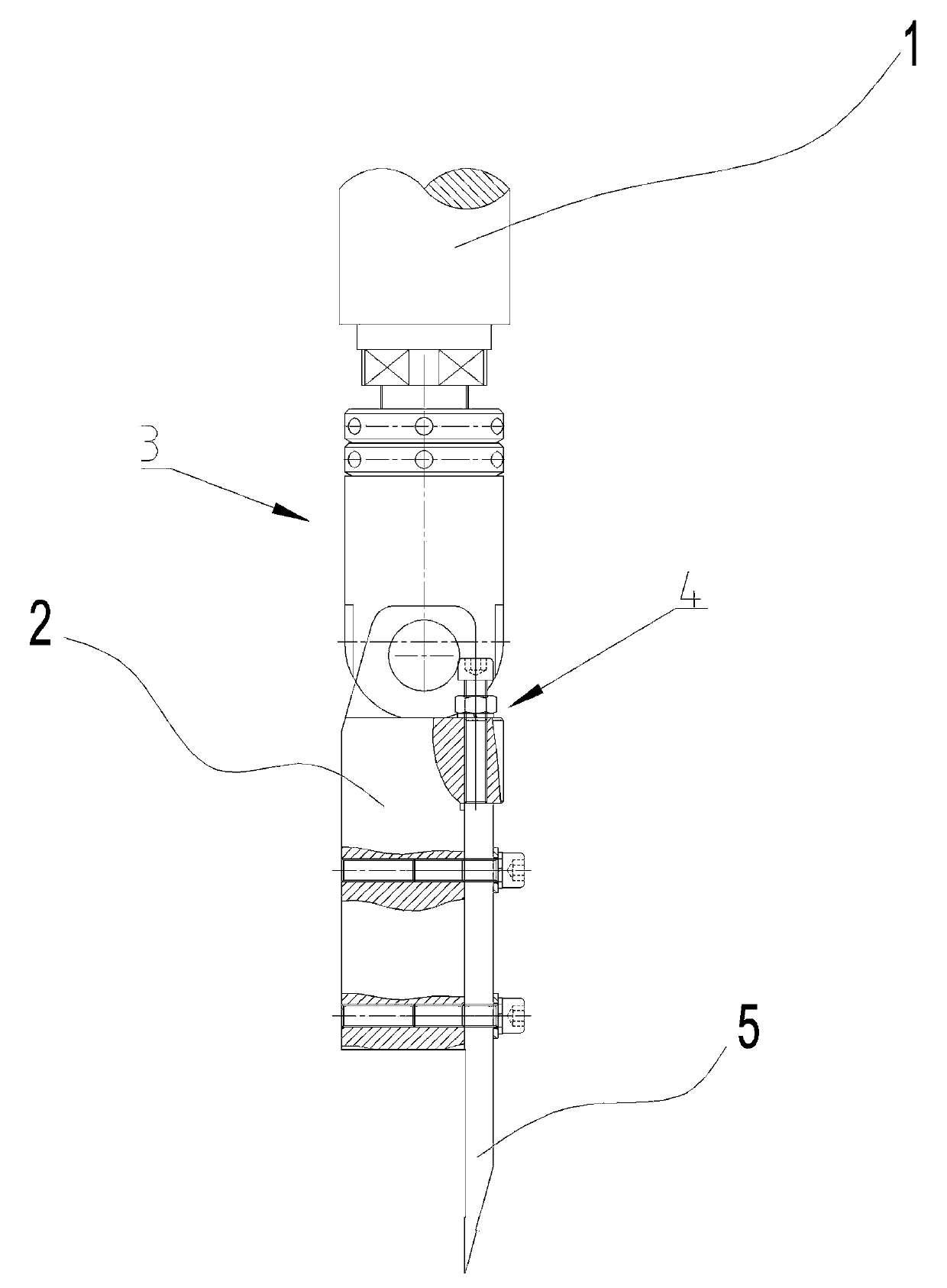

[0016] Such as figure 1 , figure 2 As shown, the cutting knife adjustment device of the non-melting lead granulator provided by the present invention includes an oil cylinder head 1, an adjustment screw 3a is connected to the bottom of the oil cylinder head 1, and a lock nut 3b is arranged on the adjustment screw 3a, and the adjustment screw 3a and the nut seat below 3c is connected and matched, and the lower end of the nut seat 3c is connected to the knife rest 2; the knife rest 2 is connected to the cutter 5, and the cutter 5 is provided with four symmetrical round holes 5a, and each round hole is provided with a screw and a knife rest 2 Connection and cooperation; two symmetrical threaded holes 2a are provided on the upper part of the tool holder 2, and an adjusting bolt 4a is arranged in the threaded hole 2a, and a lock nut 4b matched with it is arranged on the adjusting bolt 4a, and the lower end of the adjusting bolt 4a is aligned with the The upper end face of cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com