High-capacity freight house of automatic vending machine

A vending machine, high-capacity technology, applied in instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. The effect of increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

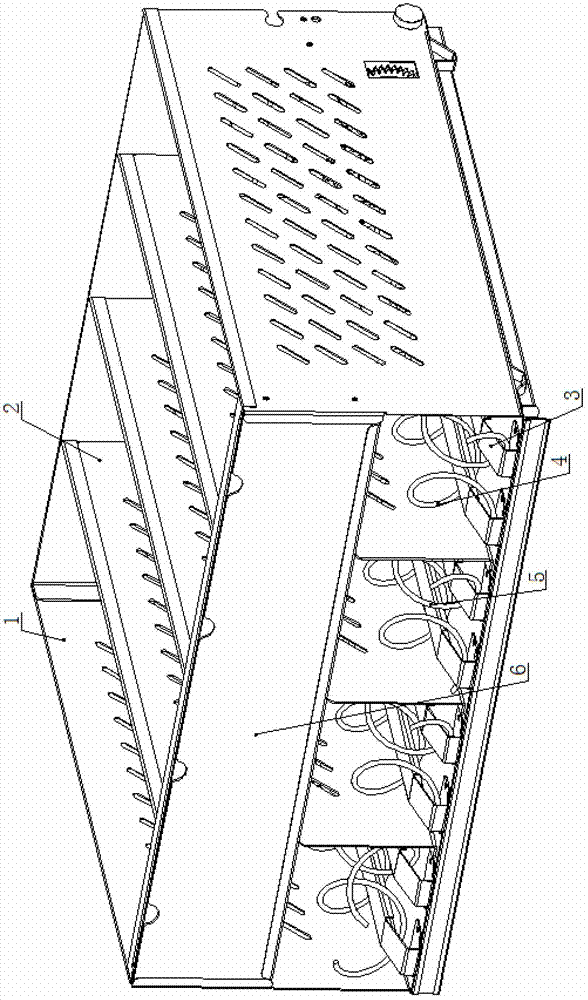

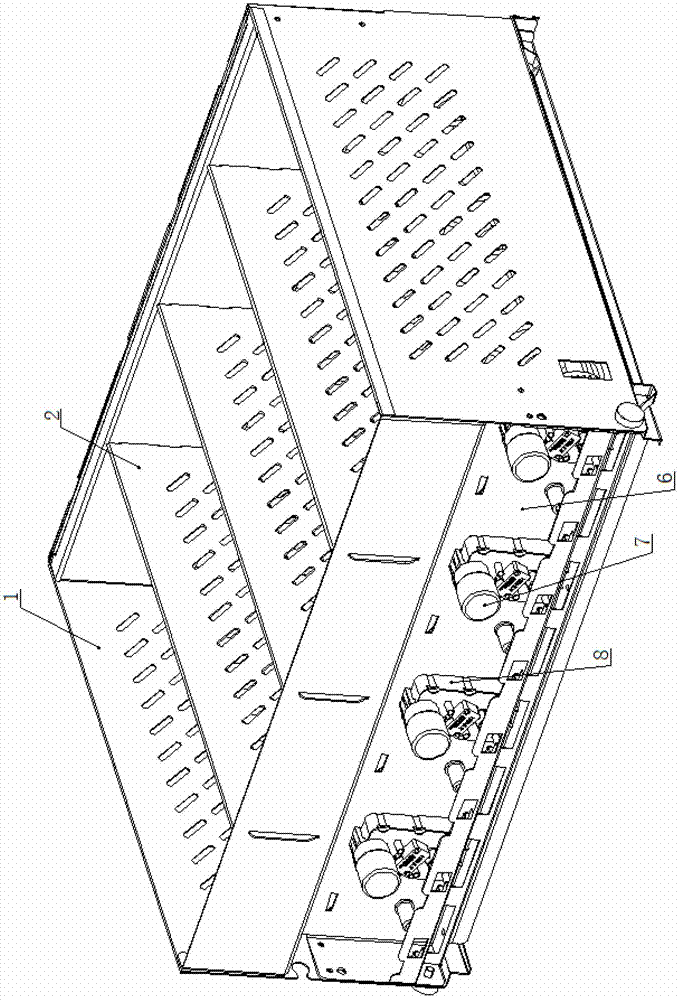

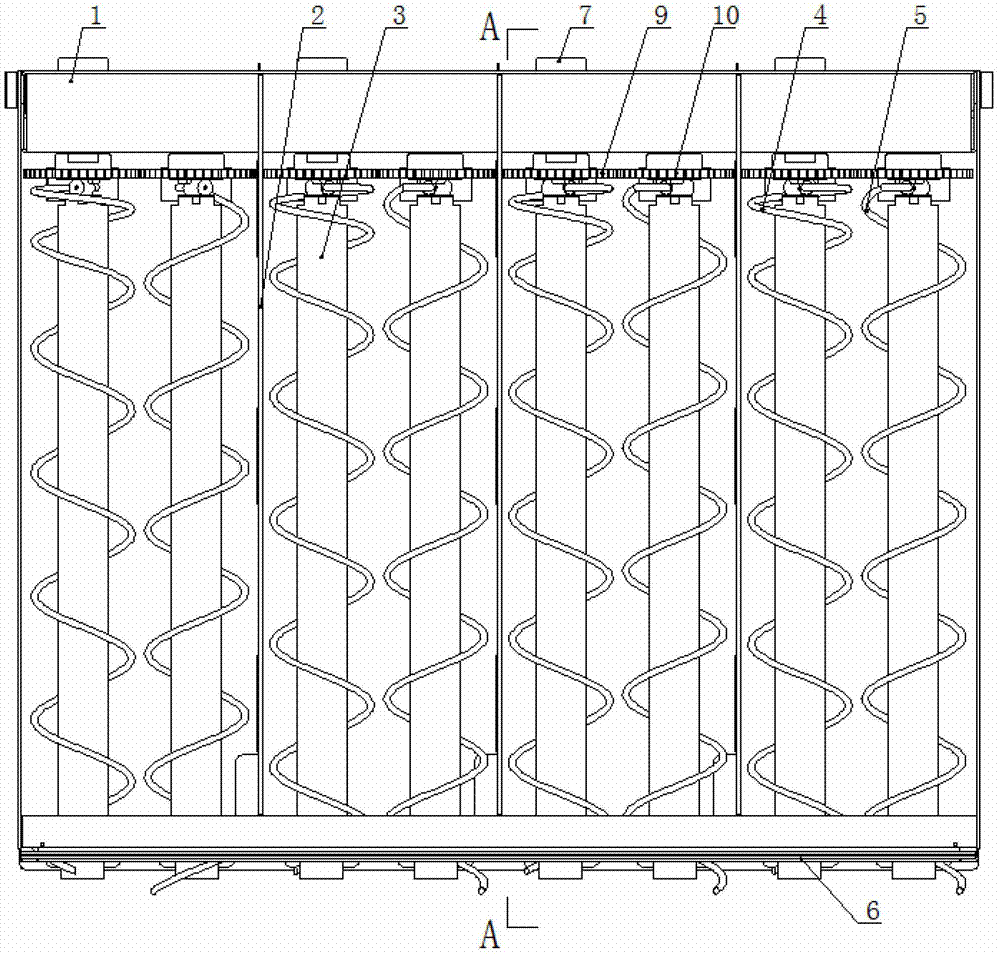

[0016] A large-capacity warehouse for vending machines, such as Figure 1~4 As shown, a plurality of partitions 2 installed at intervals in the warehouse 1 are divided into multiple cargo lanes, and a motor 7 is installed at the rear end of the warehouse. Helical springs, the innovation of the present invention is that: two helical springs 4 and 5 with the same pitch and opposite screwing directions are installed longitudinally in each of the cargo lanes, and the two helical springs rotate synchronously and in opposite directions. All vertically wear a supporting plate 3 in each helical spring, and a baffle plate 6 is installed above the front end of the warehouse, and the vertical height H from the bottom surface of the baffle plate to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com