High current inductor assembly

A technology for inductor windings and inductors, which is applied in the direction of inductors, fixed inductors, transformers/inductor coils/windings/connections, etc., which can solve the problem of not firmly connecting the circuit board, the circuit board cannot be installed on the same plane, and occupies a large area Space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

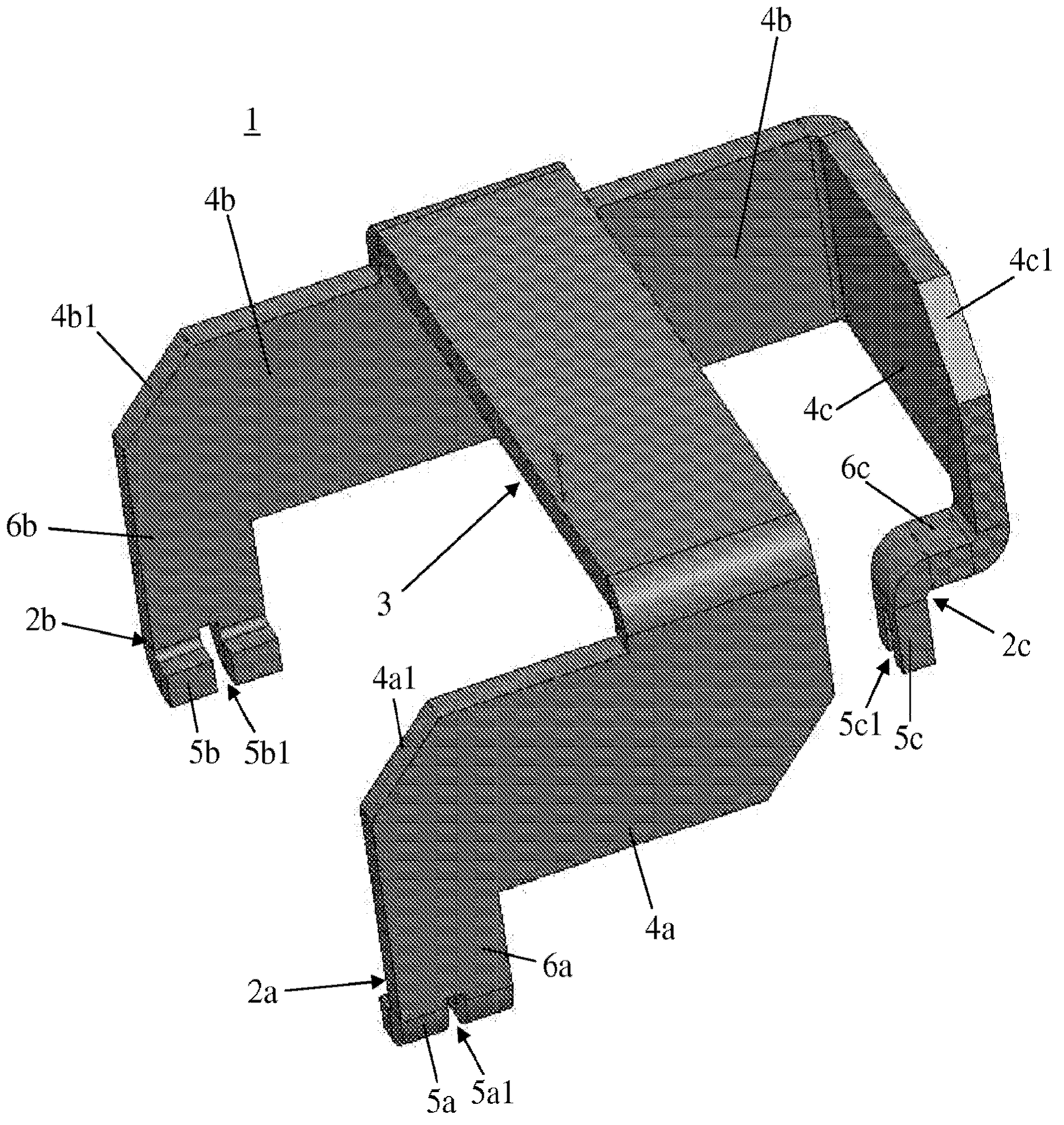

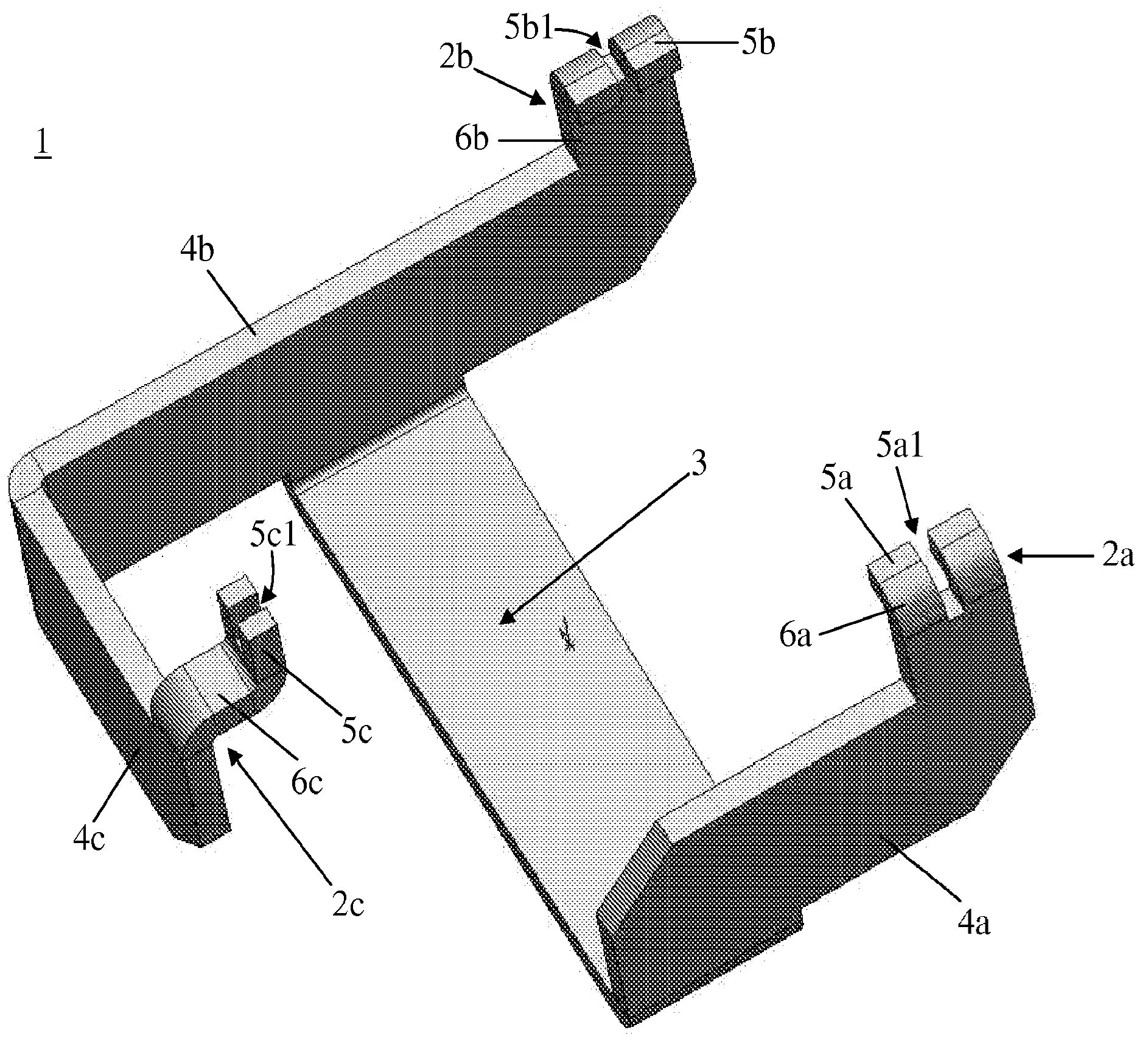

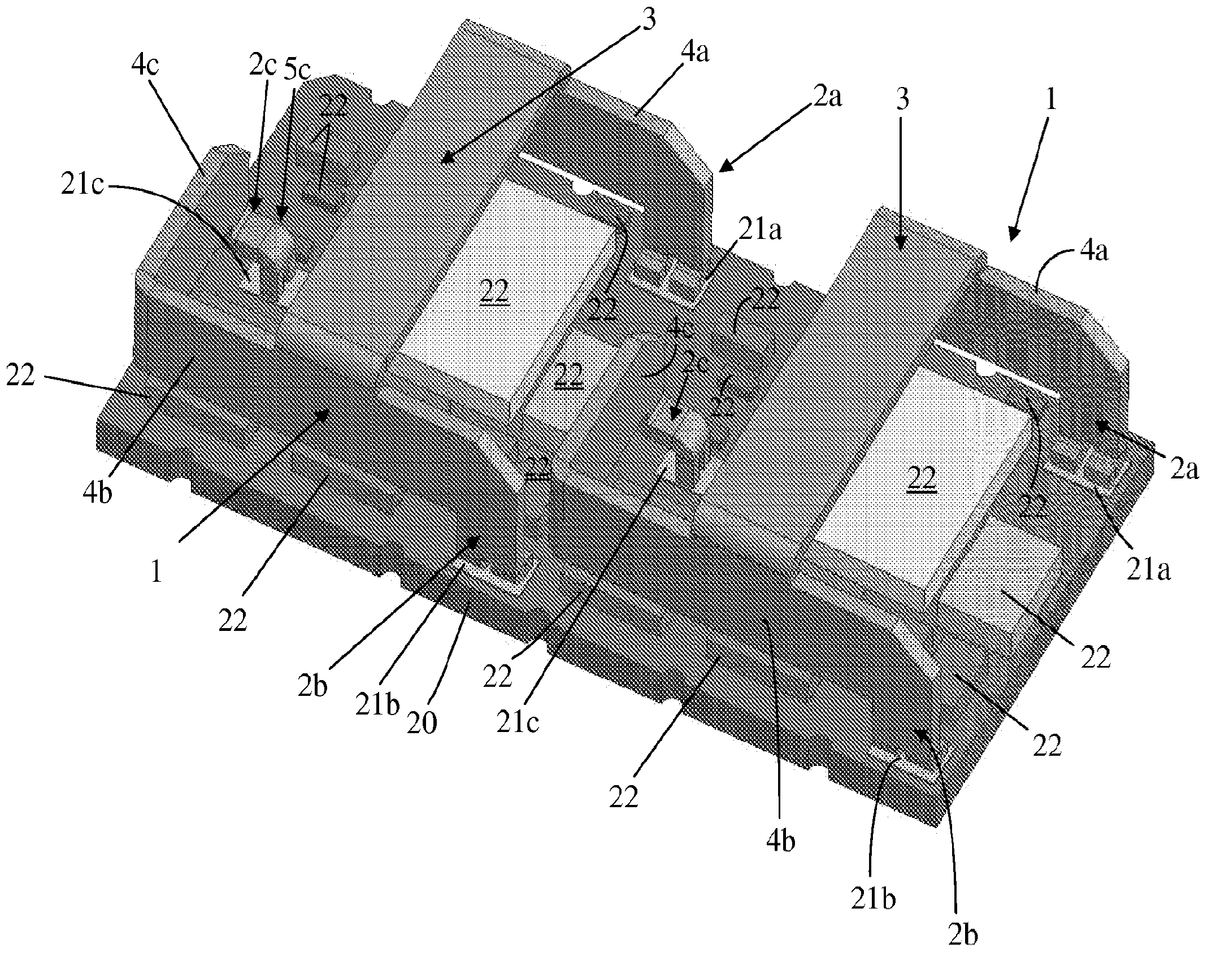

[0019] as in Figure 1-4 As shown in , an inductor winding 1 according to a preferred embodiment of the present invention preferably comprises a middle part 3 and first, second and third legs 2a, 2b and 2c, preferably, for example, first, second and third legs 2a, 2b and 2c are arranged in a tripod structure and are connected to the middle part 3 by first, second and third arms 4a, 4b and 4c. The middle part 3 extends between the first arm 4a and the second arm 4b, and is connected to the first arm 4a and the second arm 4b. Preferably, one end of the middle part 3 is connected to the end of the first arm 4a, and the other end of the middle part 3 is connected to the central part of the second arm 4b. However, the intermediate portion 3 may be arranged to extend between any suitable portions of the first, second and third arms 4a, 4b and 4c, and to connect ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap