Bubble brick production device

A production device and technology of foam bricks, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency and difficulty in satisfying automatic production, and achieve the effects of high production efficiency, automatic production and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

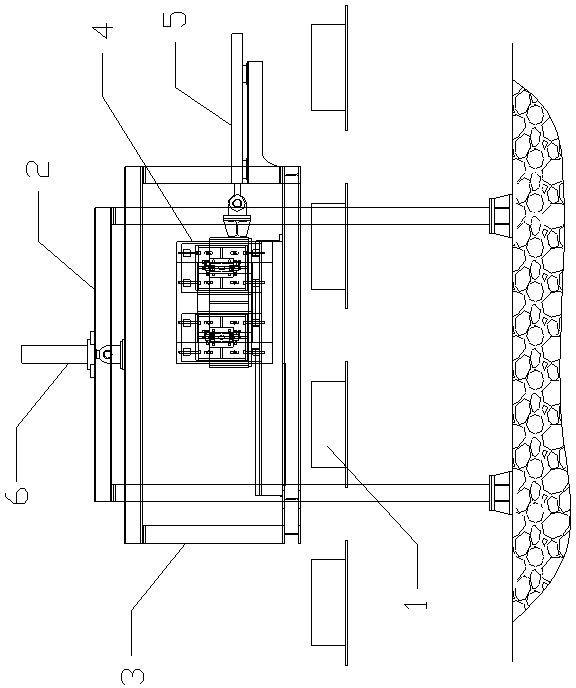

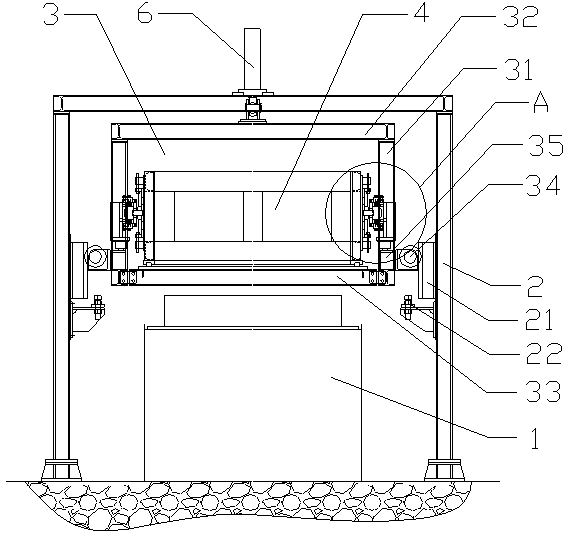

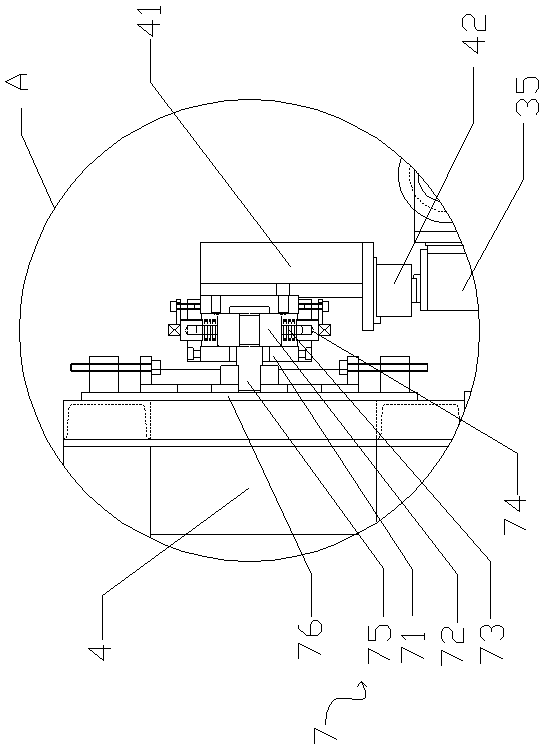

[0032] see Figure 1~Figure 5 , a kind of foam brick production device that the present invention relates to, it comprises conveying device 1, fixed bracket 2, moving frame 3, feeder box 4, horizontal moving mechanism 5 and vertical moving mechanism 6, and described conveying device 1 is a conveyor belt or Conveying rollers, the front and rear sides of the fixed support 2 are provided with vertical guide rails 21, the bottom of the vertical guide rails 21 is provided with a buffer seat 22, the mobile frame 3 includes a frame body 31, and the frame body 31 The top is provided with a cover plate 32, the bottom of the frame body 31 is provided with a template 33, the front and rear sides of the frame body 31 are provided with vertical guide wheels 34, and the vertical guide wheels 34 are arranged on the vertical guide rails 21, The front and rear sides of the inside of the frame 31 are provided with transverse guide rails 35, the bottom of the material box 4 is hollowed out, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com