Poked wheel part and poked wheel bottle delivering device

One component, No. 1 technology, applied in the field of dial components and dial bottle conveying devices, can solve problems affecting product quality and personnel safety, inaccuracy, short handover time, etc., to achieve accurate and rapid vacuum formation and disappearance, avoid Exploding bottle phenomenon, the effect of ensuring accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

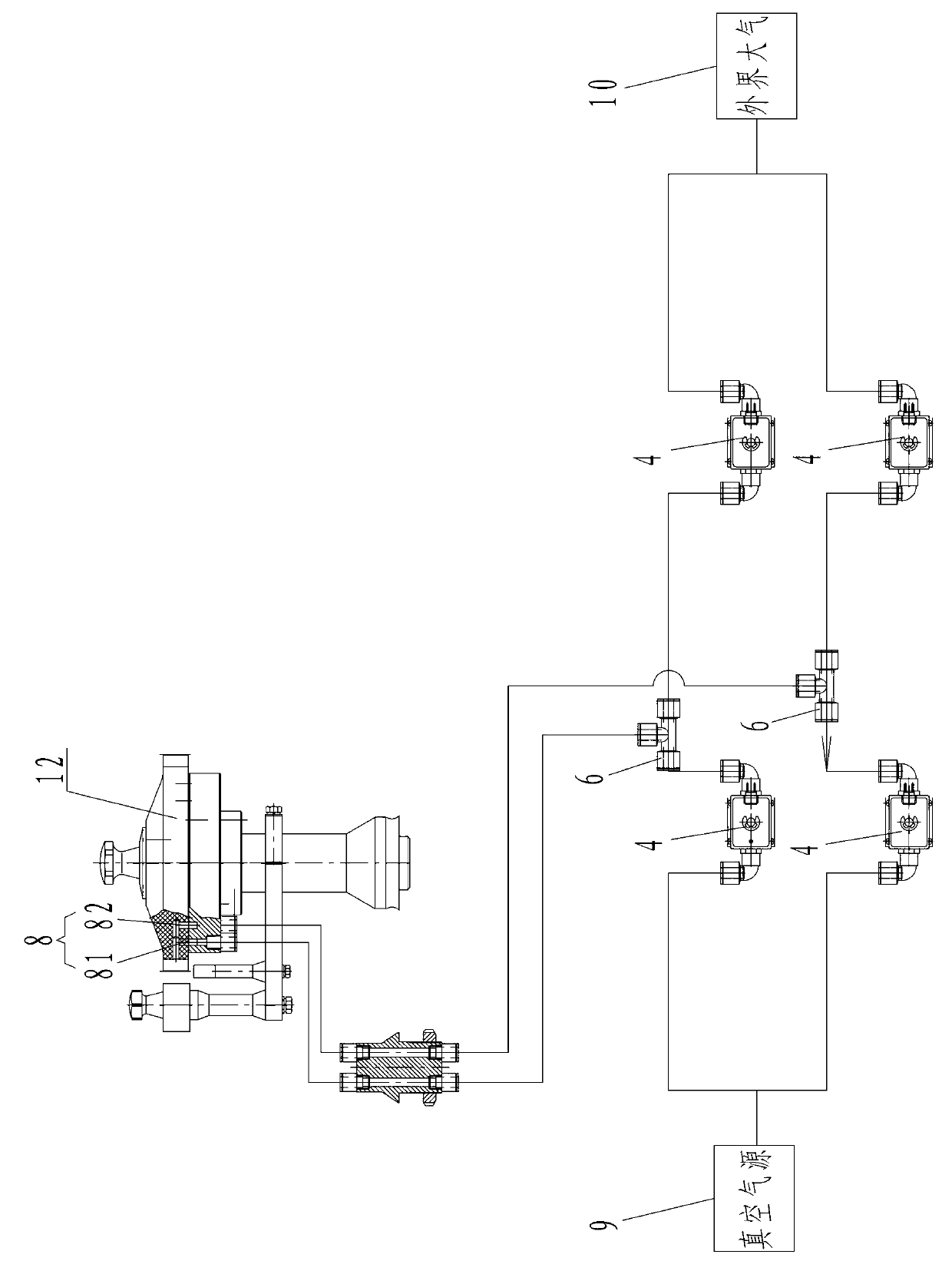

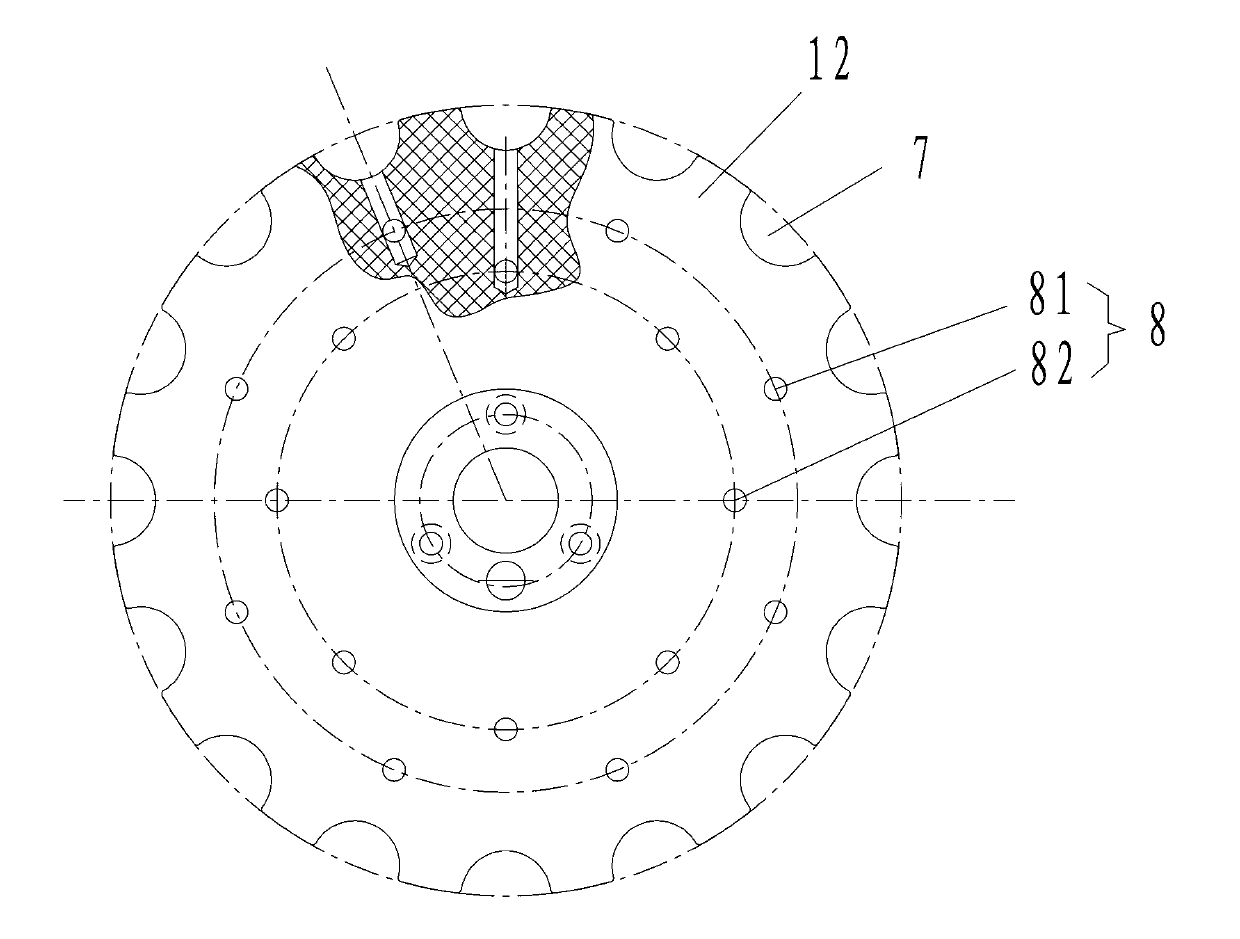

[0023] Such as figure 1 , image 3 , Figure 4 As shown, an embodiment of a dial component of the present invention includes a dial 12 and more than one vacuum control circuit connected to the dial 12, and the dial 12 is provided with a plurality of vacuum channels corresponding to the dial groove 7 of itself. 8. Each vacuum control line includes an air circuit connection assembly with at least three interface ports. The three interface ports of the air circuit connection assembly are respectively connected to the vacuum channel 8, the vacuum air source 9 and the external atmosphere 10 through the air circuit. The circuit connection component is switched and communicated with the vacuum air source 9 and the external atmosphere 10, that is, when the vacuum channel 8 is connected with the vacuum air source 9, the vacuum channel 8 is disconnected from the external atmosphere 10; when the vacuum channel 8 is disconnected from the vacuum air source 9, The vacuum channel 8 commun...

Embodiment 2

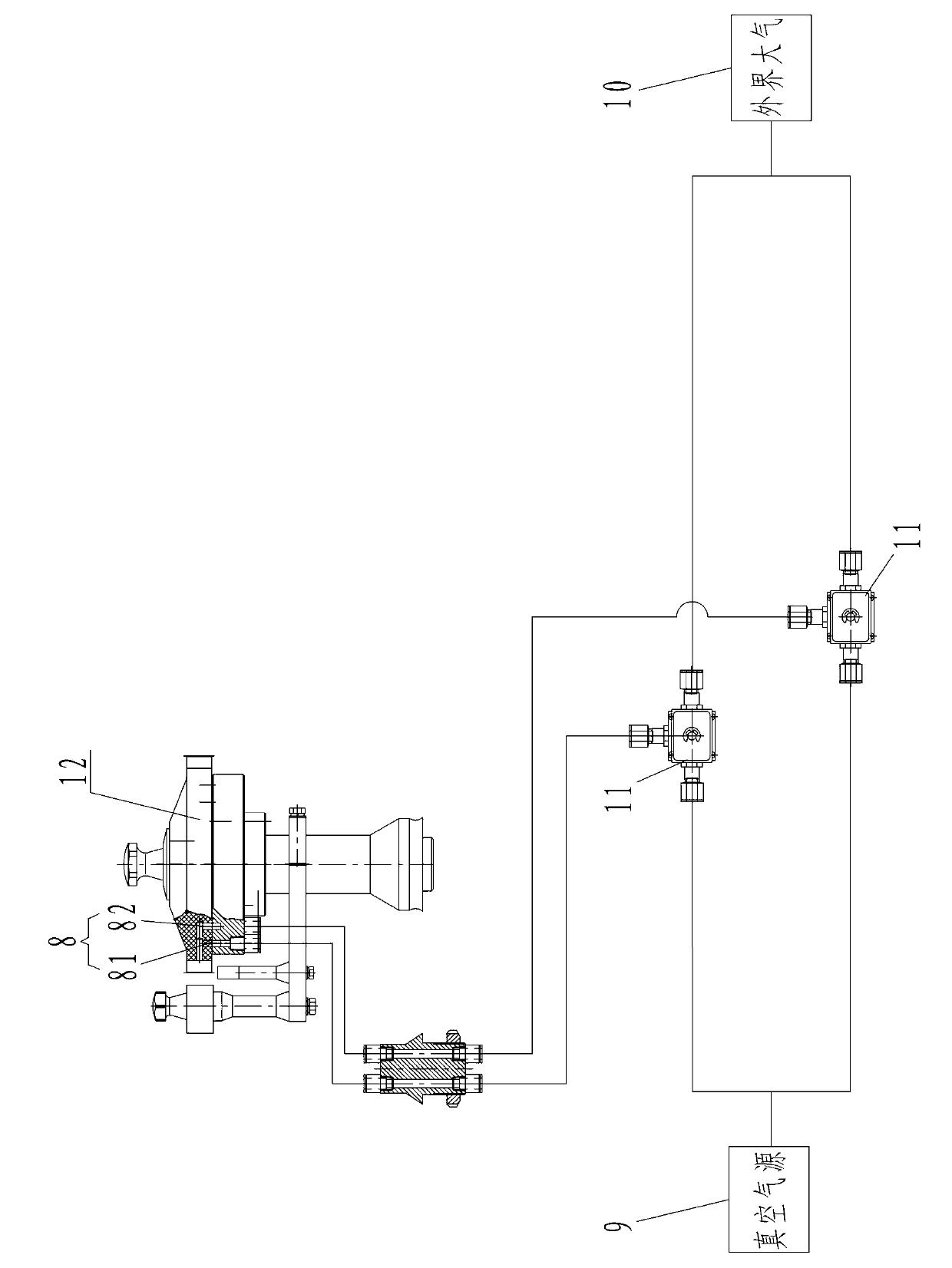

[0028] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of the dial component embodiment 1, the difference is that: the air circuit connection assembly is a three-way solenoid valve 11 with one in two out or two in and one out, with one in two out three Take the one-way solenoid valve 11 as an example. The inlet port of the three-way solenoid valve 11 is connected to the vacuum passage 8, and the two outlet ports of the three-way solenoid valve 11 are connected to the vacuum air source 9 and the external atmosphere 10 through the air path respectively. When conveying the bottle body normally, the port connected with the vacuum air source 9 of the three-way solenoid valve 11 is opened, and the port connected with the external atmosphere 10 is closed, and a vacuum is formed in the vacuum channel 8 on the dial 12, so that the bottle body is adsorbed on the dial wheel 12. In dial slot 7 on the top. When transferring the bottle body with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com