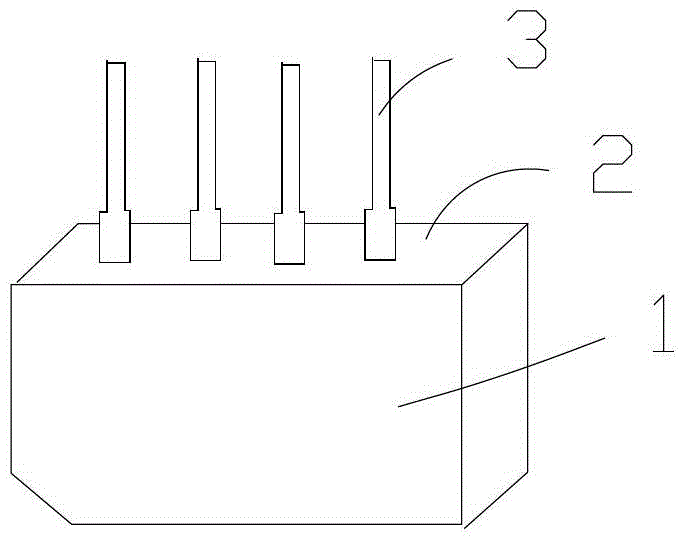

Automatic code printing device of flat rectifier bridge

An automatic coding and rectifying bridge technology, which is applied to vibrating conveyors, transportation and packaging, conveyor objects, etc., can solve problems such as low efficiency and high labor intensity, and achieve the effect of improving coding efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

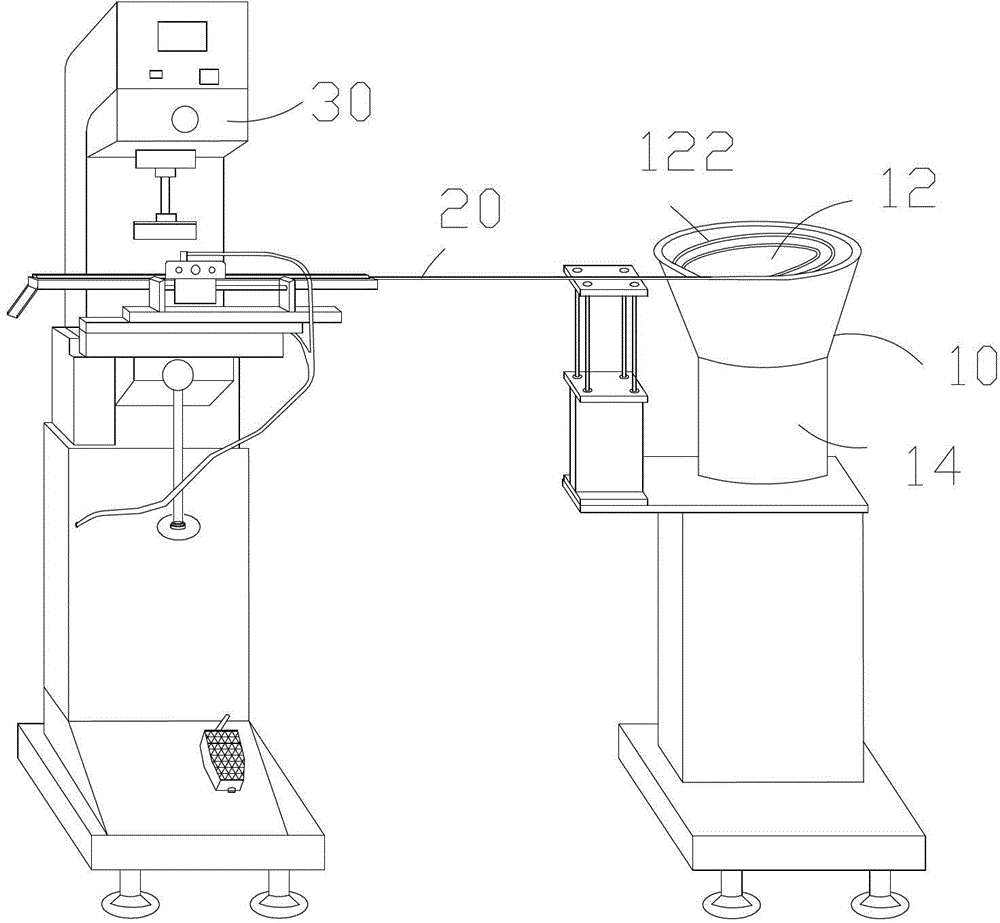

[0021] see figure 2 As shown, the automatic coding device of the flat rectifier bridge of the present invention includes a feeding device 10 , a coding device 20 , and a coding machine 30 .

[0022] The coding machine 30 can use existing coding machines on the market.

[0023] The feeding device 10 includes a feeding chute 12 and a vibrating device 14 located at the lower part of the feeding chute 12 . The inner periphery of the feeding trough 12 is provided with a channel 122 that goes up spirally. First, all the flat rectifier bridges that need to be coded are poured into the feeding trough 12, and the vibration of the vibration device 14 drives the flat rectifier bridges to spiral up along the channel 122 in sequence until reaching the code device 20.

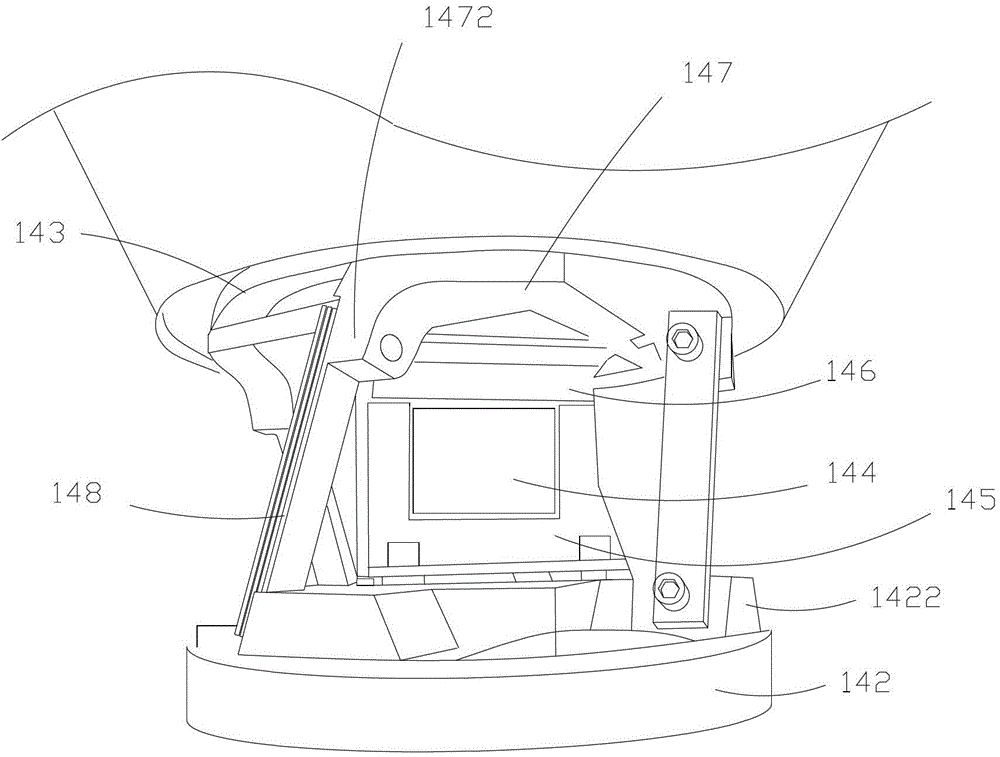

[0024] see image 3 As shown, the vibrating device 14 includes a housing ( image 3 Middle shell has been removed), bottom plate 142, top plate 143, coil 144, first magnetic steel 145, second magnetic steel 146, fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com