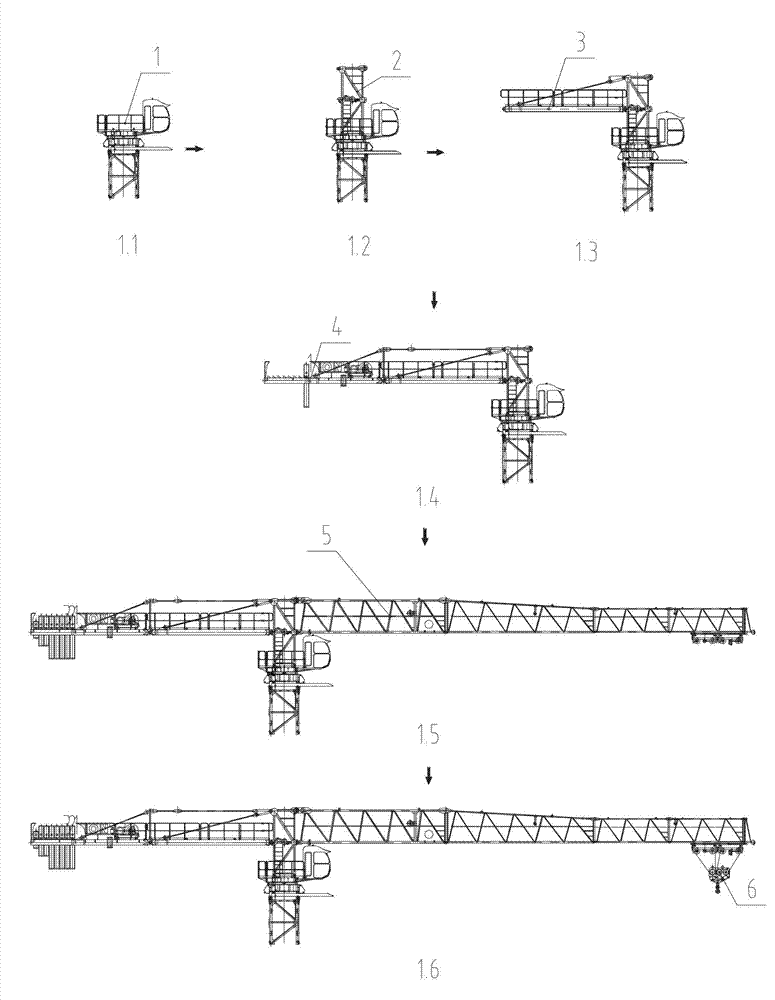

Combined arm joint of crane, crane and mounting method of crane

An installation method and a crane technology, which are applied to cranes, transportation and packaging, and load hanging components, etc., can solve the problems of complicated installation process and many assembly parts, and achieve the goals of reducing high-altitude operations, simplifying production and installation, and facilitating safe production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0030] The combined jib section of the crane of the present invention is particularly suitable for tower cranes.

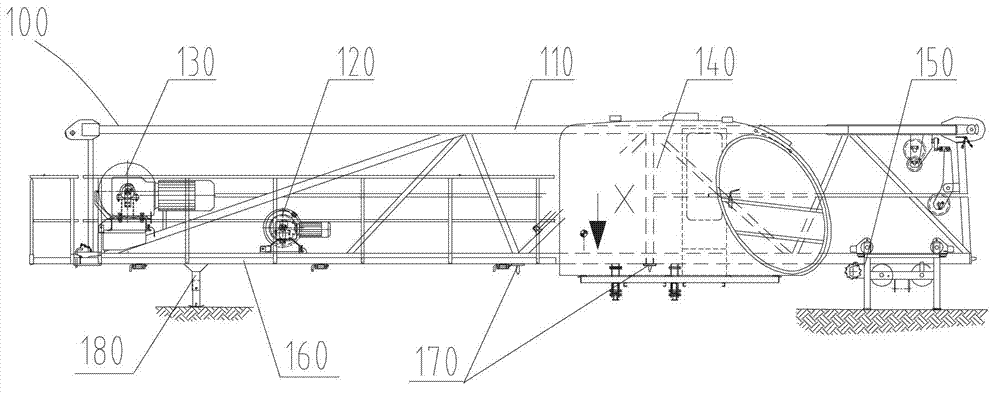

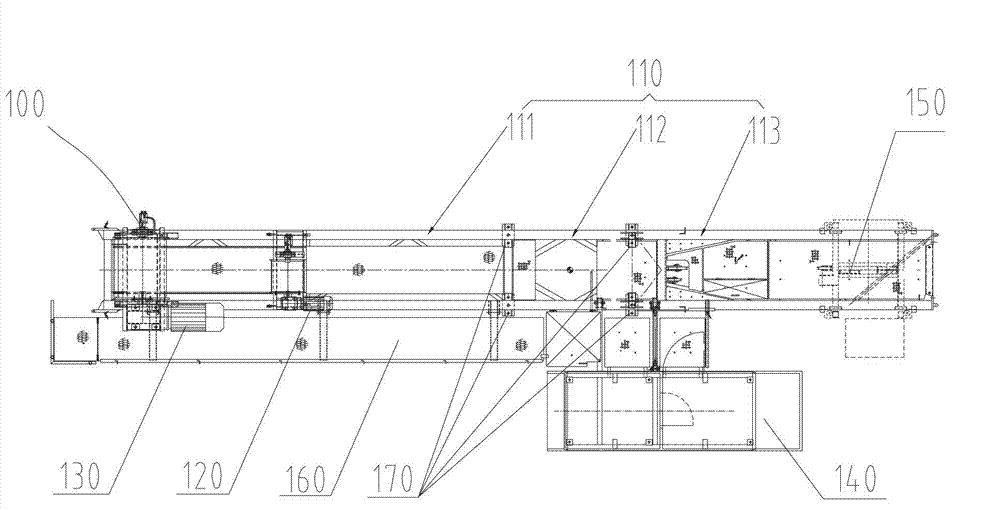

[0031] Such as Figure 2 to Figure 4 As shown, the combined jib section 100 mainly includes a jib section body 110 and a connecting portion 170 disposed on the jib section body 110 , wherein the connecting portion 170 is located between the opposite first end and the second end of the jib section body 110 , It is used to connect with the upper end of the slewing assembly 300 of the crane; in the boom section body 110, the part where the connecting part 170 is located forms the slewing tower body segment 112, and the part between the slewing tower body segment 112 and the first end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com