Dynamic real-time cutting depth control method based on load of sugarcane harvesting mechanical cutterhead

A technology of harvesting machinery and real-time control, applied in the fields of harvesters, electrical program control, agricultural machinery and implements, etc., can solve the problems of undiscovered and reduced, and achieve the effect of low cost and guaranteeing the quality of perennial roots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A dynamic real-time control method for depth of cut based on the load of a sugarcane harvesting mechanical cutter head, the method includes the following steps:

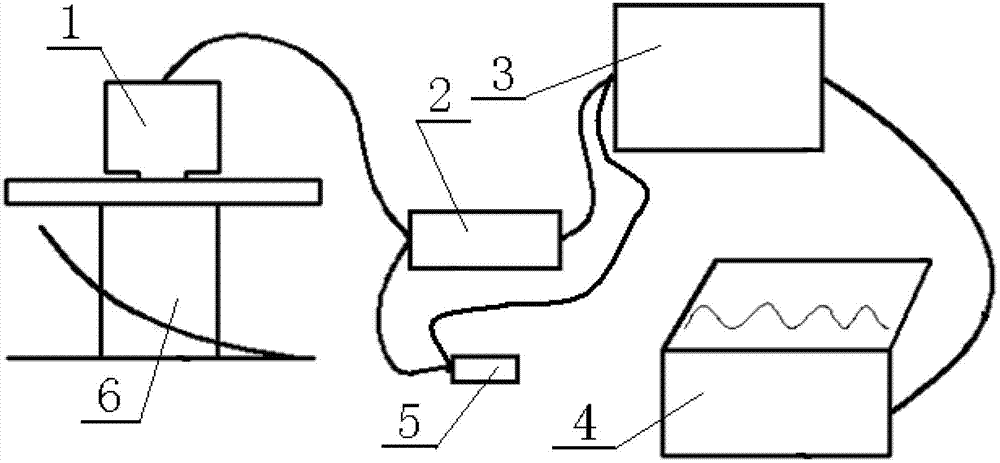

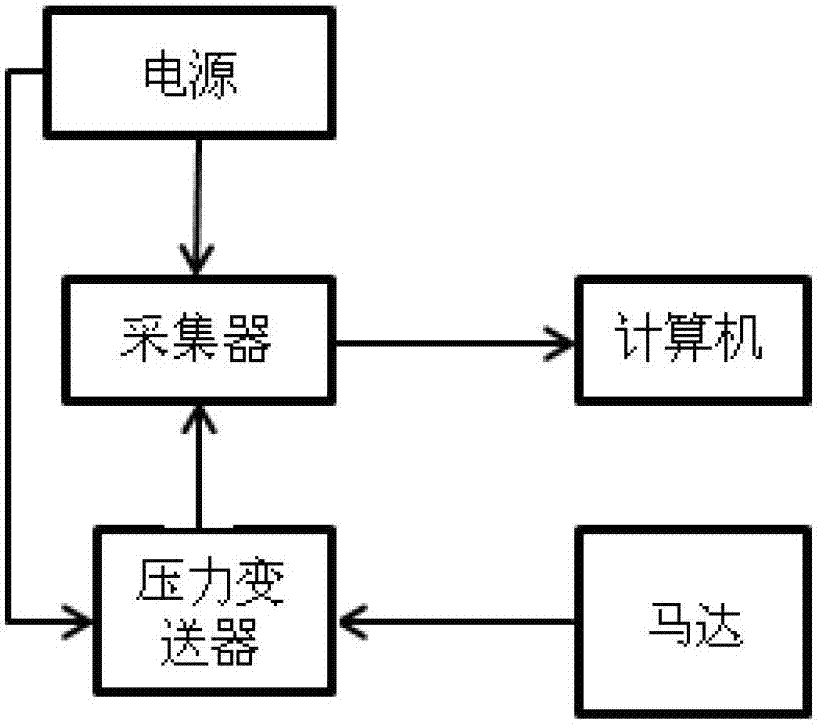

[0033] ①Install a data measuring device on the sugarcane harvester, and sample on the cutter; the data measuring device includes a pressure transmitter 2, a collector 3 and a microcomputer 4; the pressure transmitter 2 is connected to the input end of the collector 3 respectively , the hydraulic motor 1 of the sugarcane harvester cutter 6 is connected; the output end of the collector 3 is connected with the input end of the microcomputer 4; the output end of the microcomputer 4 is connected with the power control system of the sugarcane harvesting machine; the pressure transmitter 2 and collector 3 are also respectively connected with a 24V DC power supply 5;

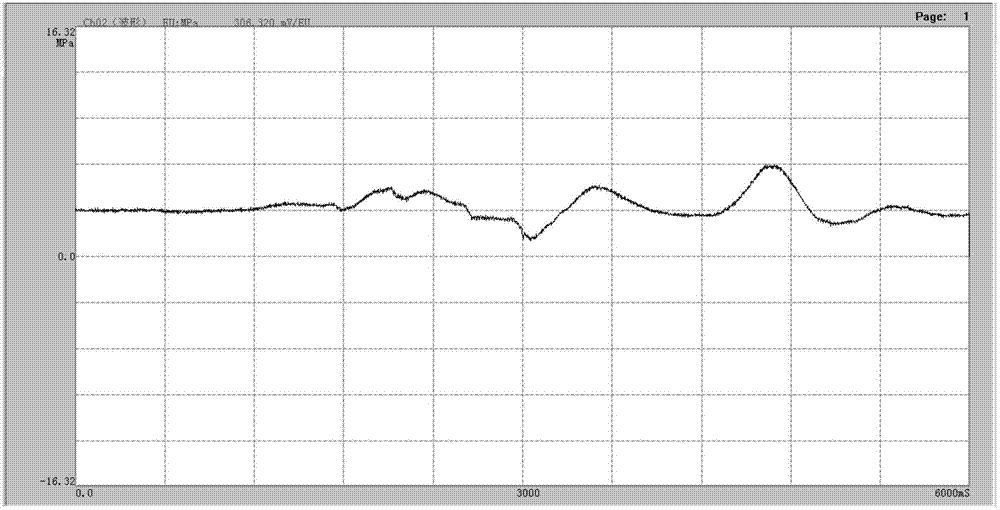

[0034] ②Collect data and process data: at a certain cutting depth h of the cutting head, collect the load pressure P data in real time, and then perfor...

Embodiment 2

[0039] A dynamic real-time control method for depth of cut based on the load of a sugarcane harvesting mechanical cutter head, the method includes the following steps:

[0040]①Install a data measuring device on the sugarcane harvester, and sample on the cutter; the data measuring device includes a pressure transmitter 2, a collector 3 and a tablet computer 4; the pressure transmitter 2 is connected to the input end of the collector 3 respectively , the hydraulic motor 1 of the sugarcane harvester cutter 6 is connected; the output end of the collector 3 is connected with the input end of the tablet computer 4; the output end of the tablet computer 4 is connected with the power control system of the sugarcane harvesting machine; the pressure transmitter 2 and collector 3 are also respectively connected with a 24V DC power supply 5;

[0041] ②Collect data and process data: at a certain cutting depth h of the cutting head, collect the load pressure P data in real time, and then p...

Embodiment 3

[0046] A dynamic real-time control method for depth of cut based on the load of a sugarcane harvesting mechanical cutter head, the method includes the following steps:

[0047] ①Install a data measuring device on the sugarcane harvester and sample on the cutter; the data measuring device includes a pressure transmitter 2, a collector 3 and a single-chip microcomputer 4; the pressure transmitter 2 is connected to the input end of the collector 3, the sugarcane The hydraulic motor 1 of the harvester cutter 6 is connected; the output end of the collector 3 is connected with the input end of the single-chip microcomputer 4; the output end of the single-chip microcomputer 4 is connected with the power control system of the sugarcane harvesting machine; the pressure transmitter 2 and the collector 3 are also respectively connected with a 24V DC power supply 5;

[0048] ②Collect data and process data: at a certain cutting depth h of the cutting head, collect the load pressure P data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com