Buoyancy vertical pipe of self-balancing ups and downs cultivation net cage

A self-balancing and net cage technology, which is applied in fish farming, application, climate change adaptation, etc., can solve the problems affecting the net cage balance ups and downs, improper setting of intake and exhaust valves, and insufficient simplification of structure, etc., to achieve simplified structure, The effect of smooth intake and exhaust process and accelerated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

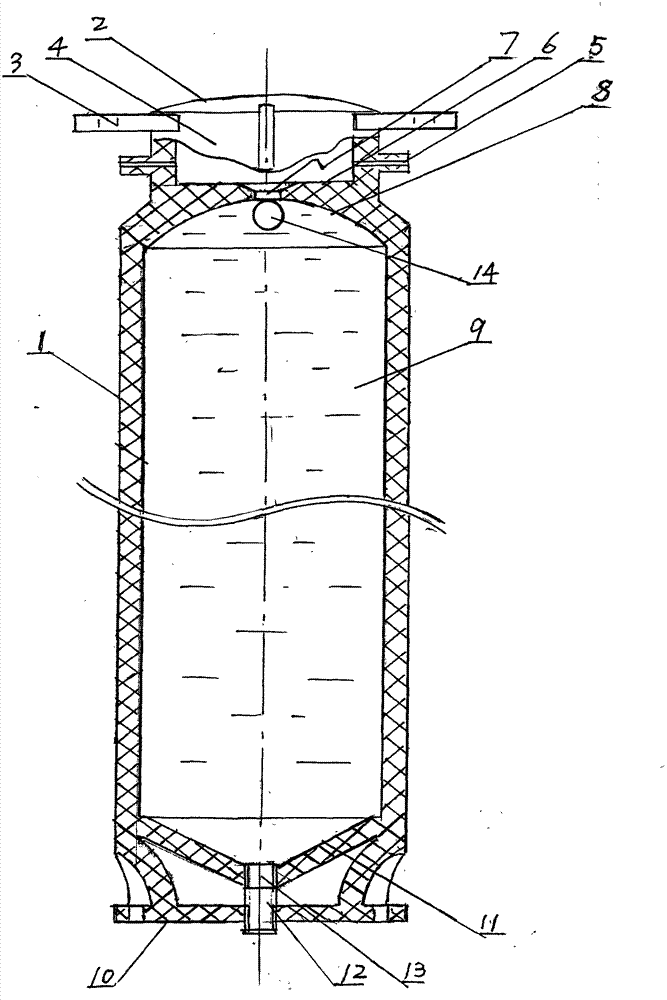

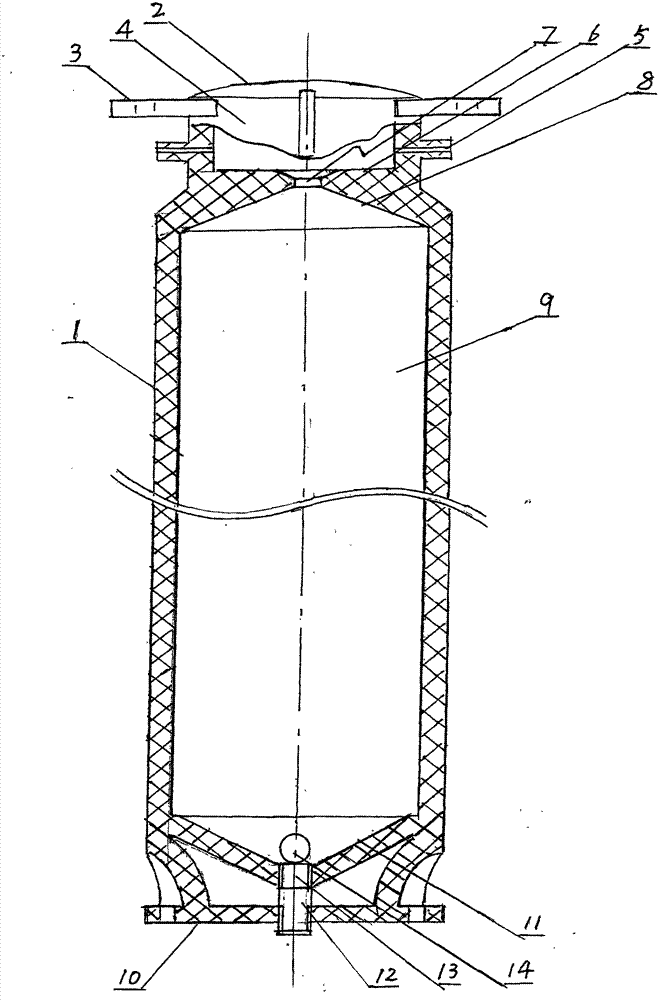

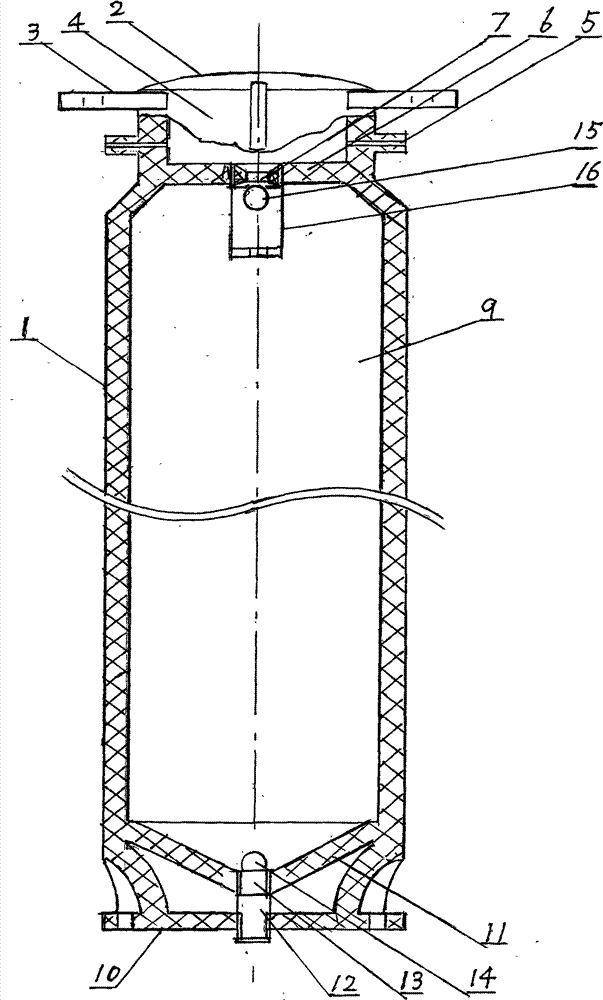

[0011] In order to facilitate the comparison of new and old technical solutions, the present invention attaches image 3 A sectional view of the buoyancy riser of the disclosed existing culture net cage is provided, and the top of the pipe cavity is provided with an inlet and exhaust valve 16, and the attached Figure 4 A sectional view of the disclosed existing buoyancy riser intake and exhaust valve is given. Its working principle is that when the net cage is inflated and drained to float, the gas is filled into the intake and exhaust valve 16 through the intake and exhaust ports 7, and the water in the valve is discharged into the tube cavity 9 through the bottom center through hole 19, and when the floating ball 15 seals Block the central through hole 19, water is pressed into the lumen through the auxiliary through hole 20, the water in the lumen is discharged out of the pipe through the bottom inlet and outlet valve, and finally the bottom inlet and outlet 13 is blocked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com