Total heat exchange haze removal all-in-one machine with thin design and universal front and back sides

A technology of full heat exchange and integrated machine, which is applied in the field of full heat exchange and haze removal integrated machine, can solve the problems of complicated and circuitous design of air supply and exhaust flow channels, heavy structural design, and inability to install at will, so as to prevent the temperature from being too high. , smooth exhaust and intake, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below, examples of which are shown in the accompanying drawings, and the embodiments described below by referring to the accompanying drawings are exemplary and are intended to explain the present invention so that the technical solutions of the present invention It is easier to understand and grasp, but cannot be construed as a limitation to the present invention.

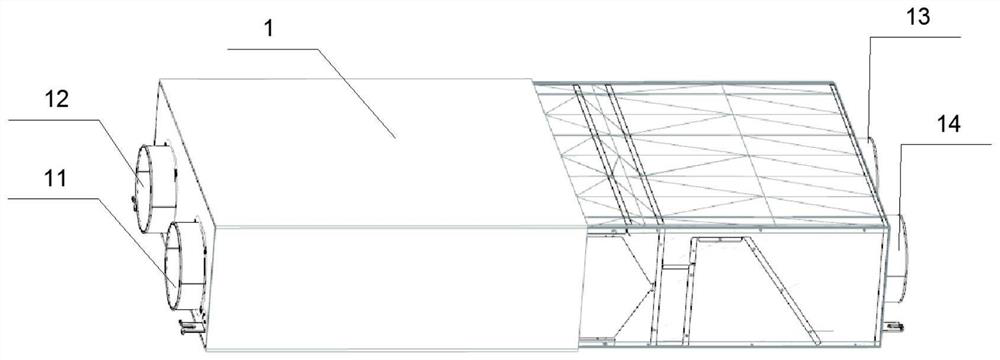

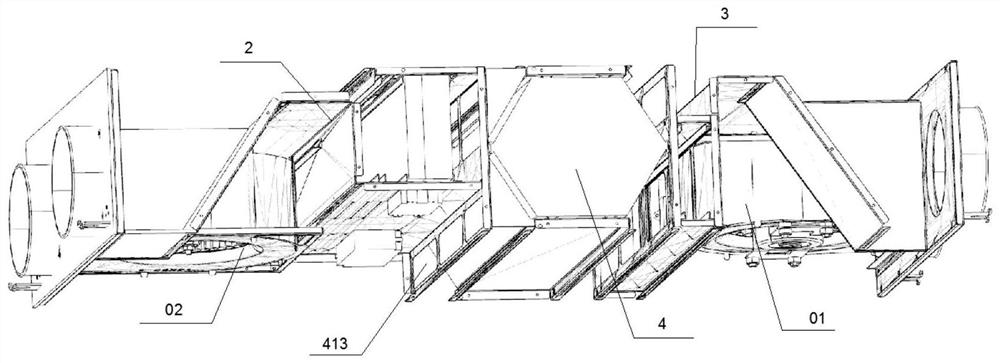

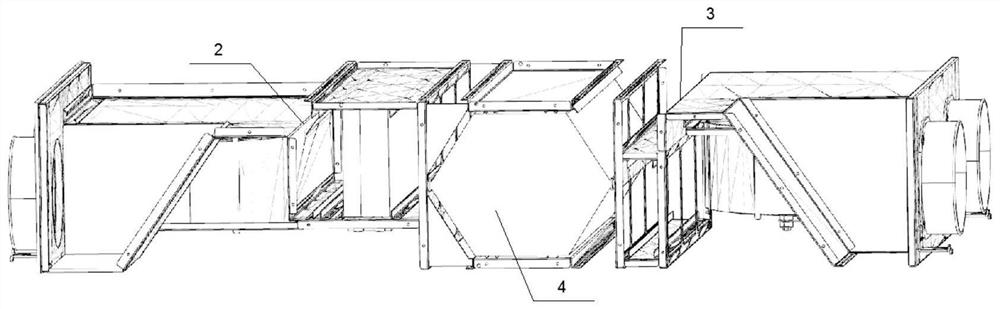

[0030] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 8 The all-in-one heat exchange and haze removal all-in-one machine with a slim design, which is universally used in front and back, includes a closed body 1, and the body 1 is equipped with a first partition 2, a second partition 3 and a heat exchange core 4, and the first partition 2 The front half of the body 1 is divided into an upper front air chamber 201 and a lower front air outlet chamber 202, and the second partition 3 divides the rear half of the body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com