A method for improving the wear resistance of the valve disc cone surface and reducing the surface roughness

A technology of surface roughness and valve disc cone, which is applied in the field of internal combustion engine parts manufacturing, can solve the problems of difficult to achieve close to mirror surface finish, large surface roughness of valve cone surface, low sealing performance of valve cone surface, etc. The effect of grinding difference, improving finish and solving roughness difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

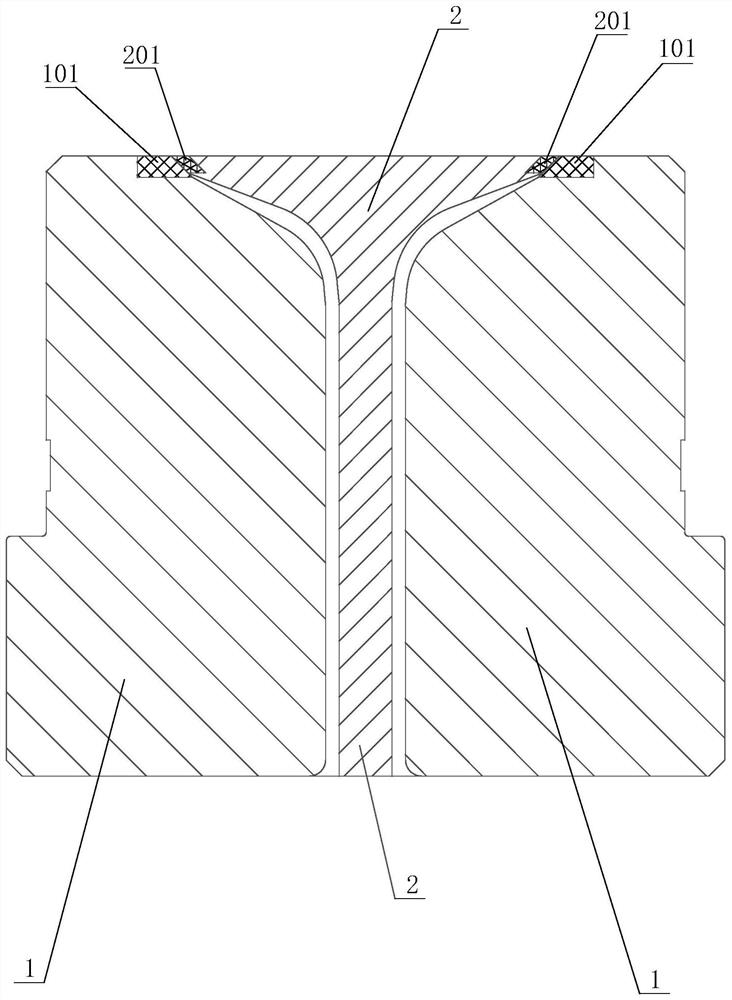

Image

Examples

Embodiment 1

[0044] A method for improving the wear resistance of the valve disc cone surface and reducing the surface roughness, comprising the following steps in sequence:

[0045] 1) The rod material is formed into a valve blank by hot upsetting or hot extrusion;

[0046] 2) Turning disc cone surface: on the valve blank obtained in step 1), the disc cone surface is produced by turning;

[0047] In step 2), the surface roughness of the disc-cone surface obtained after the control of turning is ≤ Ra1.25;

[0048] 3) finely grinding the cone surface of the disk: performing fine grinding on the cone surface of the disk produced in step 2);

[0049] In step 3), control the surface roughness of the disc-cone surface obtained after the finish grinding process is ≤ Ra0.4;

[0050] 4) Forging the conical surface of the disk: on the forging press and using a mirror forging die, perform forging treatment on the conical surface of the disk after step 3) fine grinding, and press out a layer of har...

Embodiment 2

[0056] A method for improving the wear resistance of the valve disc cone surface and reducing the surface roughness, comprising the following steps in sequence:

[0057] 1) The rod material is formed into a valve blank by hot upsetting or hot extrusion;

[0058] 2) Turning disc cone surface: on the valve blank obtained in step 1), the disc cone surface is produced by turning;

[0059] In step 2), the surface roughness of the disc-cone surface obtained after the control of turning is ≤ Ra1.25;

[0060] 3) finely grinding the cone surface of the disk: performing fine grinding on the cone surface of the disk produced in step 2);

[0061] In step 3), control the surface roughness of the disc-cone surface obtained after the finish grinding process is ≤ Ra0.4;

[0062] 4) Forging the conical surface of the disk: on the forging press and using a mirror forging die, perform forging treatment on the conical surface of the disk after step 3) fine grinding, and press out a layer of har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com