Novel numerical control twist drill

A twist drill, a new type of technology, applied in the field of drilling tools, can solve the problems of difficult sharpening and difficult chip removal of twist drills, etc., and achieve the effects of good chip removal, extended tool life, and fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

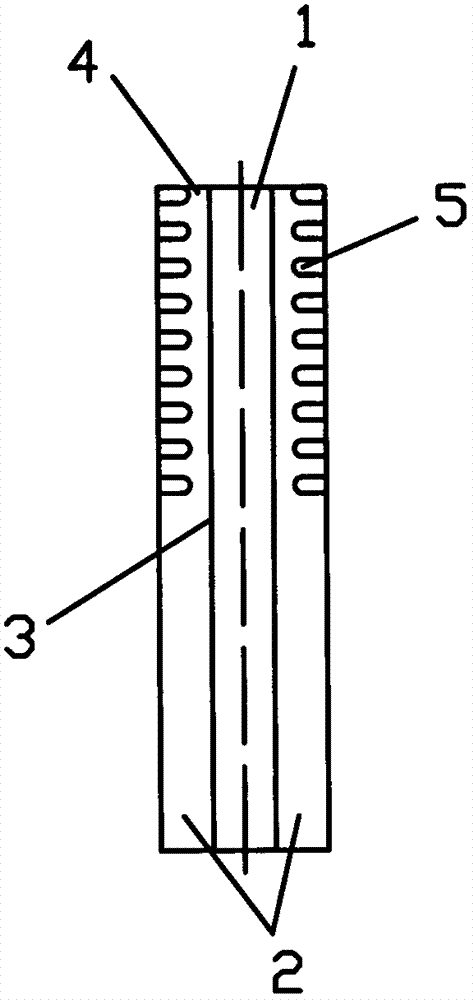

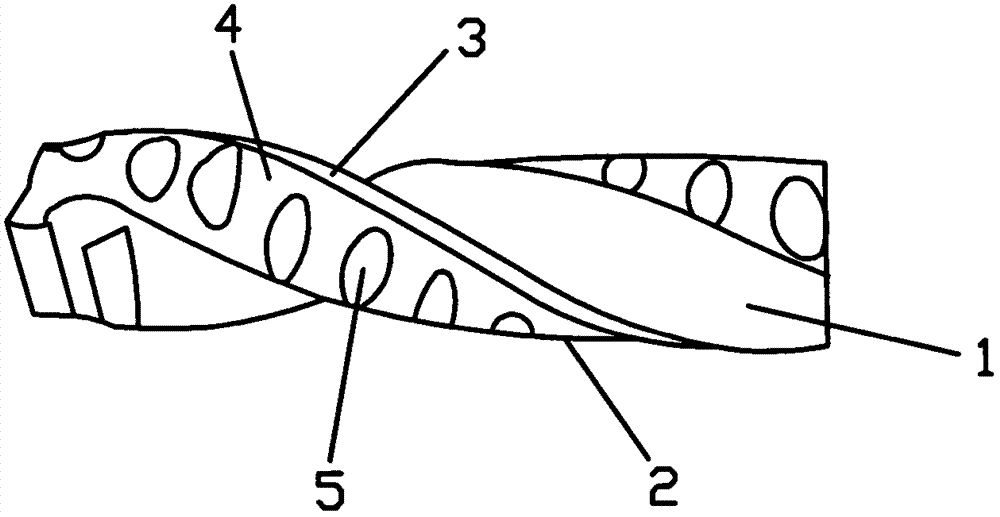

[0011] A new type of numerical control twist drill, including a drill shank and a drill bit. The drill bit is composed of a cutting edge and a guiding part. The cutting edge includes a chisel edge and two main cutting edges. The guiding part includes two spiral grooves 1 and two spiral belts 2. The spiral belt 2 includes a cutting edge 3 contacting the hole wall and a cutting edge 4 slightly lower than the cutting edge 3. A number of transverse grooves are provided on the cutting edge 4 along the longitudinal direction, which can not only contain chips, but also facilitate sharpening. The width of the groove 5 extends to the center line of the drill bit; the distance between the grooves 5 is equal, and the groove 5 can be processed before the drill bit leaves the factory, which is convenient for sharpening. The beneficial effects of the invention: the cutting edge is sharper, the drilling speed is fast, the chip removal is good, and the tool life is greatly extended.

[0012] Sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com