Yarn coiling device of winder

A technology of winding machine and yarn winding, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc. It can solve the problems of rising equipment maintenance costs, reducing production efficiency, and high requirements, and achieves simple structure and low cost. Low, the effect of meeting the exercise requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

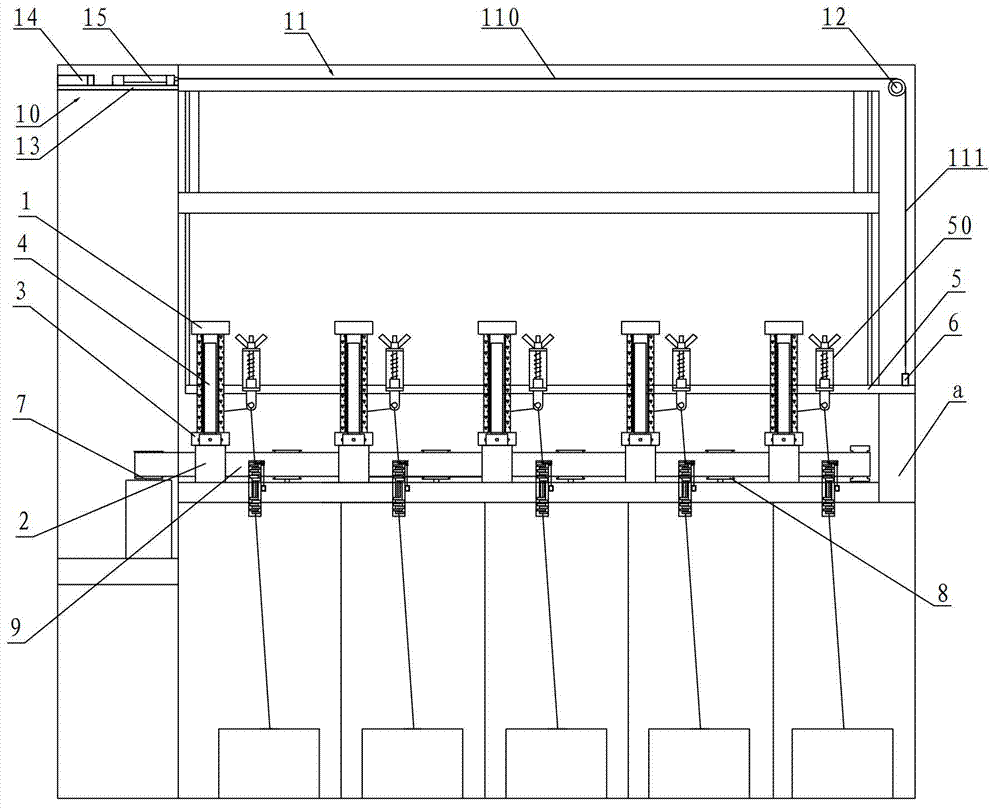

[0016] like figure 1 As shown, the yarn winding device of the winder in this embodiment includes a first yarn winding mechanism that drives the bobbin 1 to rotate around its own axis and a second mechanism that drives the yarn to move up and down along the length of the bobbin 1. Yarn winding mechanism, wherein the first yarn winding mechanism includes a spool base 2, a rotating member 3 arranged above the spool base 2 that can rotate around its own axis, and a rotating member 3 arranged on the inner wall of the spool 1. The positioning rod 4 closely matched and the first driving mechanism that drives the rotation of the rotary member 3; the second winding mechanism includes a movable frame 5 that moves up and down along the vertical direction of the frame a, a connecting piece 6 connected to one end of the movable frame 5, and a The other end of the connector 6 is connected to the second driving mechanism, and the movable frame 5 is provided with a yarn guide 50 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com