Rotation transmission device and rotation device

A transmission and rotary drive technology, applied in transmissions, fluids using vibration, belts/chains/gears, etc., can solve the problems of time-consuming and labor-intensive magnetization, high manufacturing costs, and achieve low manufacturing costs, reduce wear and contact noise. , the effect of reducing contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

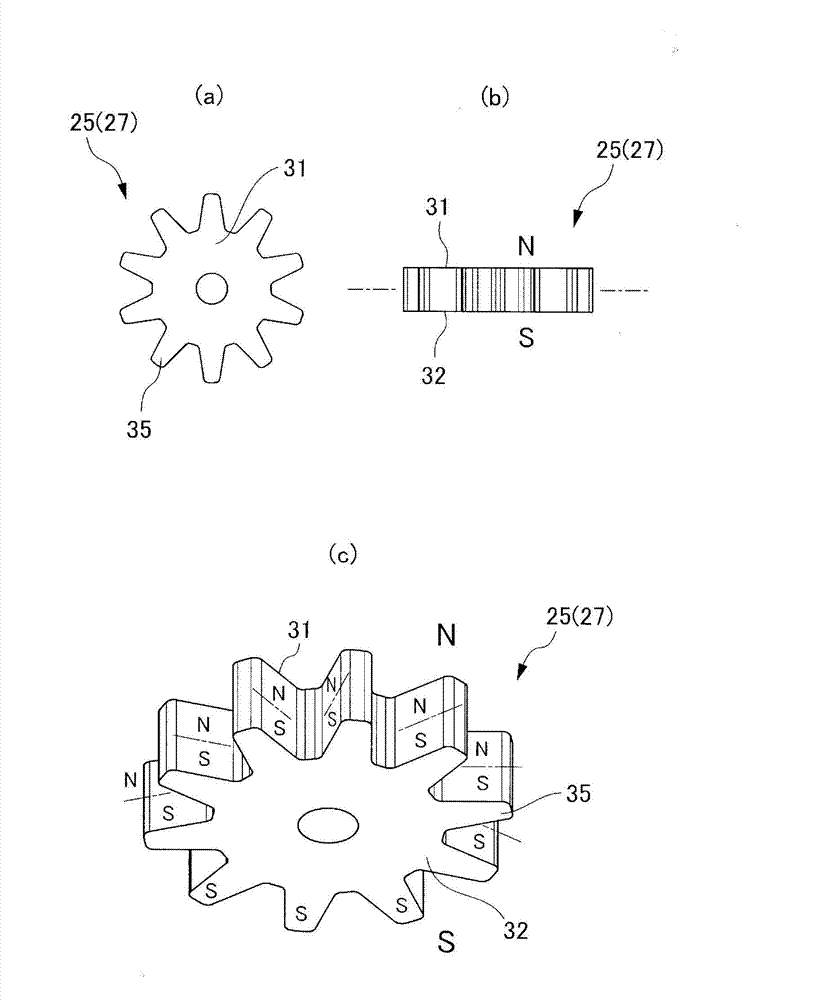

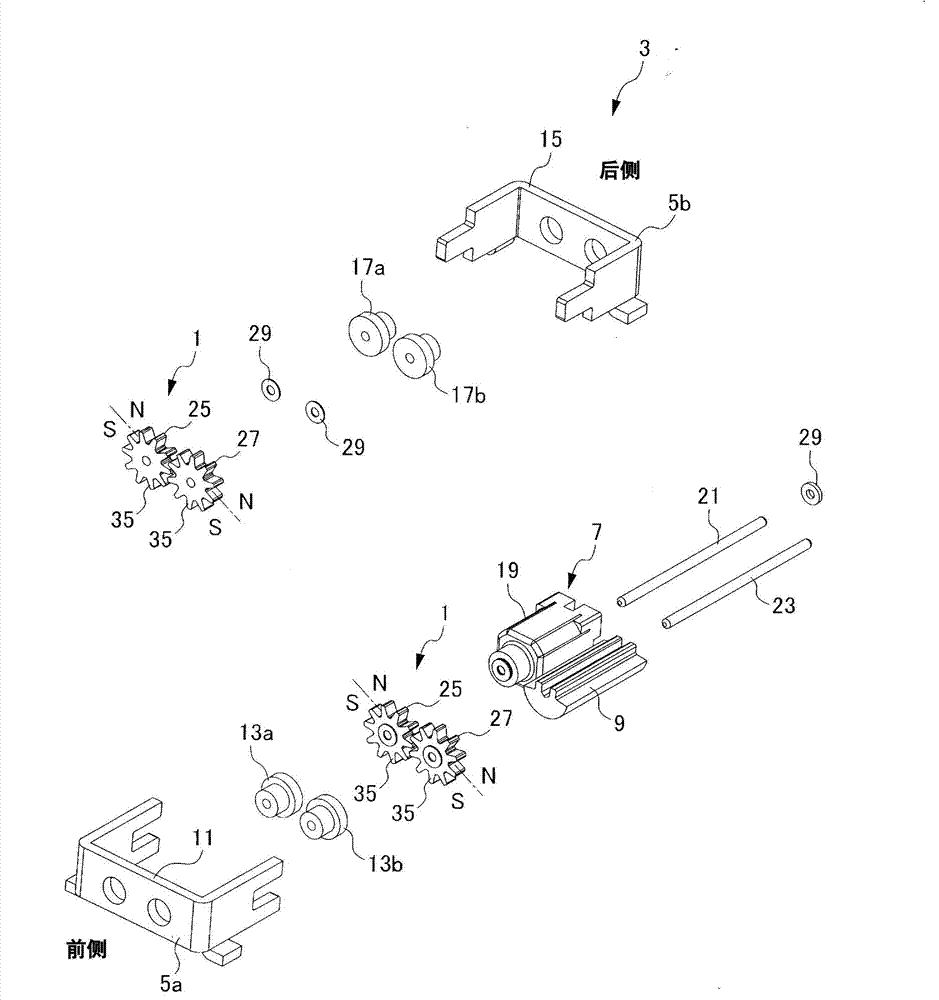

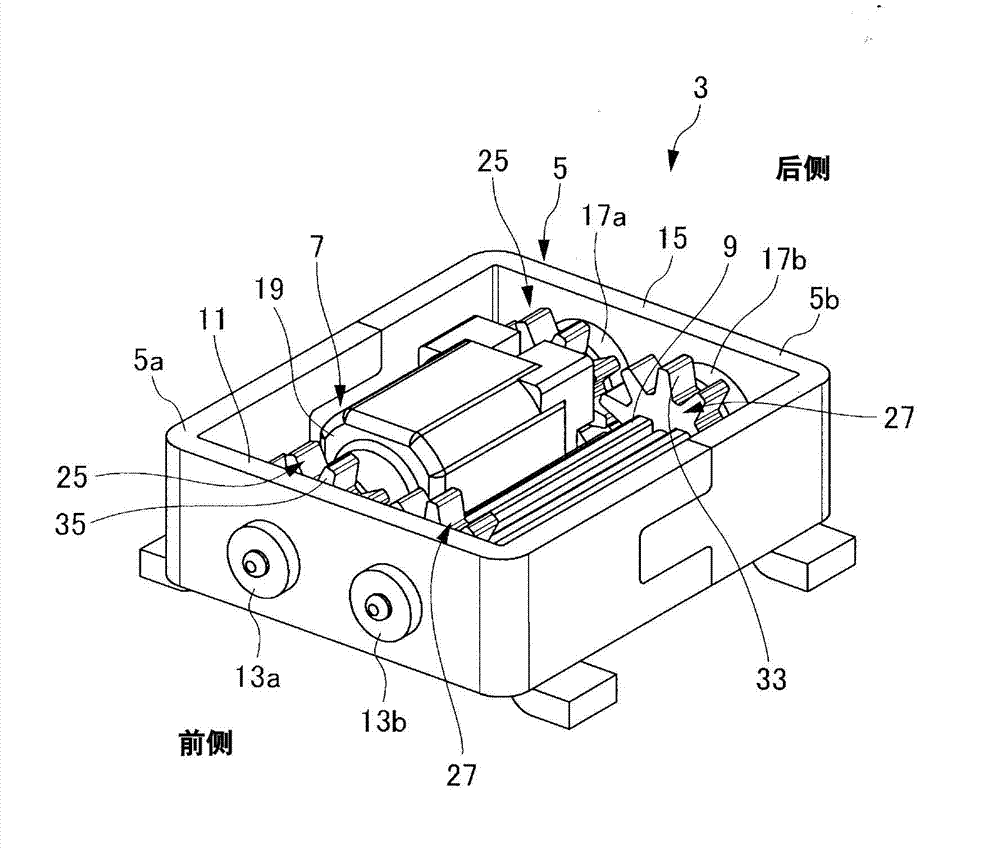

[0042] Hereinafter, each embodiment of the present invention will be described in detail. First, refer to the attached Figure 1 ~ Figure 4 , the first embodiment of the present invention will be described. The rotary transmission device 1 according to the first embodiment is a vibrating device 3 that is used on a mobile phone or the like and that vibrates when a signal is received.

[0043] This vibration device 3 such as figure 2 and image 3 As shown, there is a housing 5, a motor 7 held in the housing 5, and an eccentric weight 9.

[0044] The casing 5 is divided into a front casing portion 5 a and a rear casing portion 5 b, and these are fitted and fixed to form an annular casing 5 .

[0045] Two bearings 13a, 13b are arranged side by side on the front side wall 11 of the cabinet 5, and bearings 17a, 17b are also provided on the rear side wall 15 facing the front side wall.

[0046] The motor 7 has a motor body 19 and a motor shaft 21 . The motor shaft 21 is press-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap