Seal ring of roller

A sealing ring and roller technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of lack of elasticity, waste of cut tobacco, hard and brittle sealing ring, and achieve good weather resistance and chemical stability. Technical blank, the effect of excellent sealing performance

Inactive Publication Date: 2012-11-14

江苏润洲智造机械有限公司

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The sealing ring currently used is cut from high temperature resistant fiber cloth, which has no elasticity and poor wear resistance

During use, the sealing ring will become hard and brittle with the passage of time, and local ruptures will occur, which will lead to problems such as air leakage and wire leakage of the drum.

At the same time, it will also cause disorder in the production site and waste of cut tobacco

The normal use time of this sealing ring is about one week, and the service life is short, and it takes about 3 hours to replace a new sealing ring, which is time-consuming and labor-intensive.

[0004] In addition, the current sealing ring is limited by domestic production equipment, and the maximum diameter that can be produced is 2.5 meters. Sealing rings with larger diameters can only rely on foreign countries, and imported parts have problems such as high price, long delivery cycle, and poor service.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

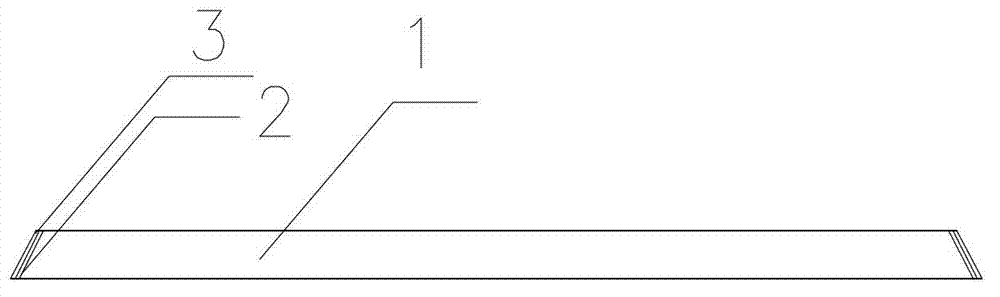

[0017] As shown in the accompanying drawings, the present invention provides a drum sealing ring, the sealing ring 1 is an isosceles trapezoid, and the angle between the bottom and the waist is 60°; the outer sides of the two waists of the sealing ring 1 are covered with fiber Cotton cloth 2 and rubber 3, the thickness of described fiber cotton cloth 2 is 3cm, the thickness of rubber 3 is 5cm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a seal ring of a roller. The seal ring is trapezoid, and fiber cotton and rubber are sequentially covered outside two sides of the seal ring. The seal ring of the roller is simple in structure, scientific in design, resistant to high temperature and good in weather resistance. Simultaneously, abrasion resistance of a seal ring body is greatly improved, and service life of the seal ring is prolonged.

Description

technical field [0001] The invention specifically relates to a drum device, in particular to a super-large drum sealing ring. Background technique [0002] In the tobacco industry, the production equipment for shredded cigarettes adopts a drum design. Such as: shredded leaf dampening machine, tobacco stem dampening machine, warming and humidifying machine, flavoring machine, etc. The drum sealing ring (hereinafter referred to as: sealing ring) on these devices is an essential key vulnerable part, and the sealing ring needs to work for a long time in a harsh environment of high temperature and humidity. [0003] The currently used sealing ring is cut from high temperature resistant fiber cloth, which has no elasticity and poor wear resistance. During use, the sealing ring will become hard and brittle over time, and partially rupture, which will lead to serious problems such as air leakage and wire leakage of the drum. Simultaneously also can cause the disorder of product...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16J15/20

Inventor 储好波

Owner 江苏润洲智造机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com