Sealed unloading groove between valve body and valve joint plate

A technology of inter-plate sealing and unloading groove, which is applied in the hydraulic field, can solve problems such as tensile damage of connecting screws, high-pressure liquid injection, and large separation force between the valve body and the valve connecting plate, so as to avoid tensile damage and improve the structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

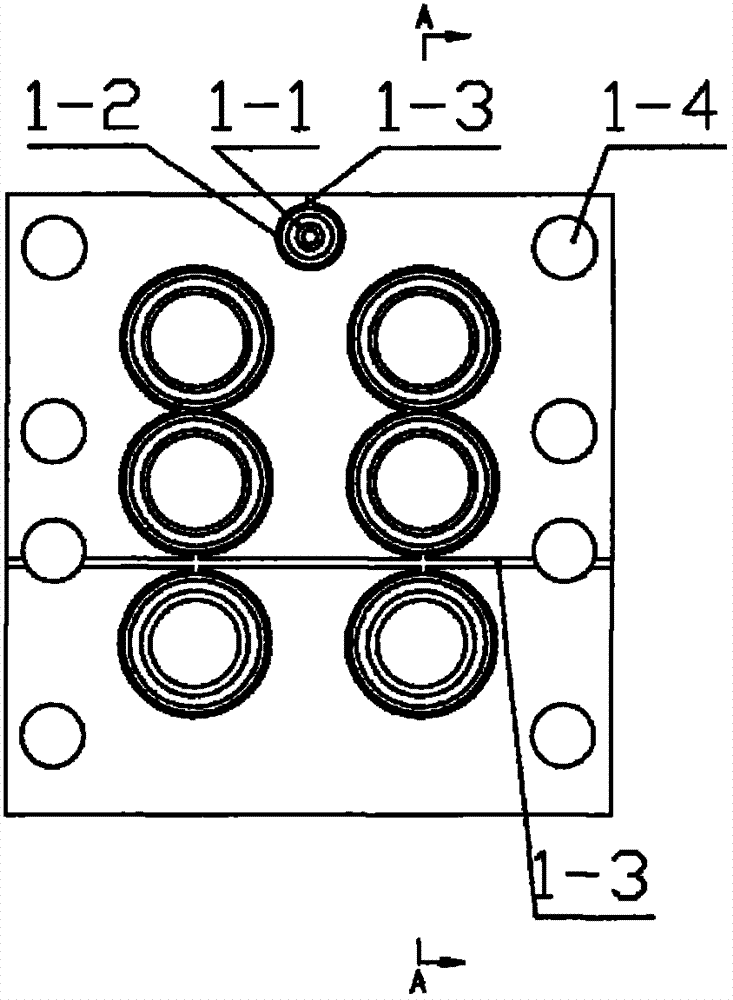

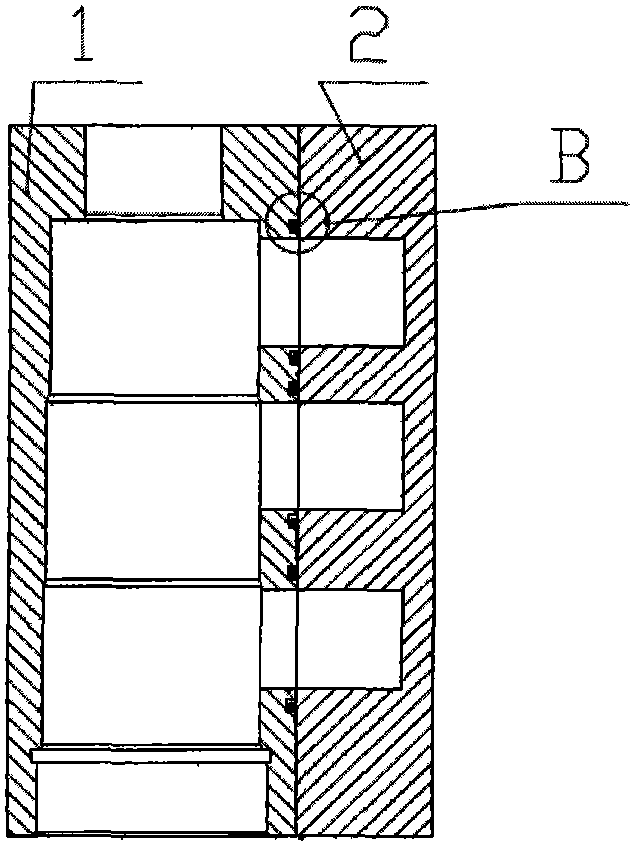

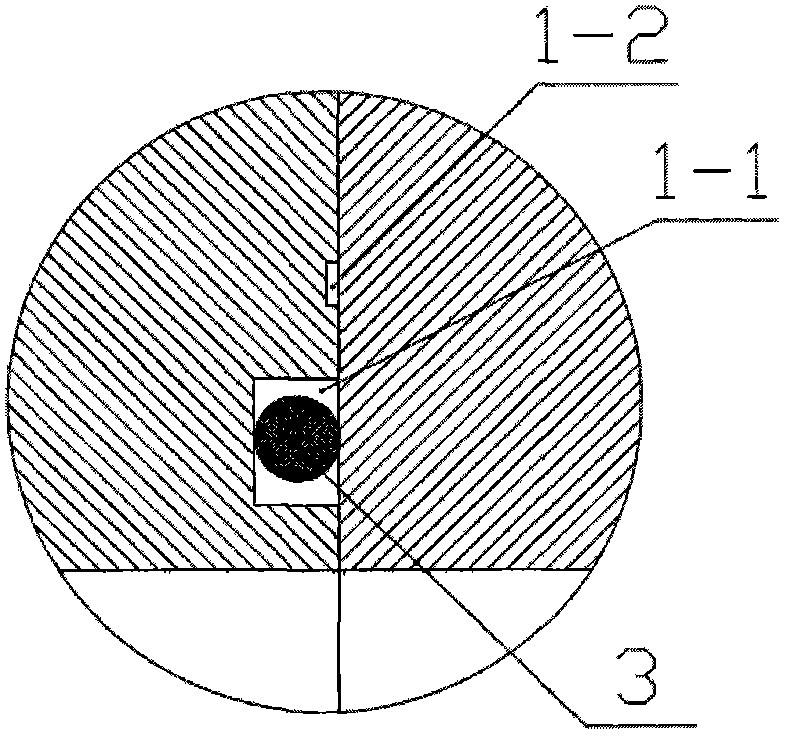

[0015] As shown in the drawings, the technical solution adopted by the present invention includes a valve body 1, a sealing groove 1-1 is processed on the contact surface of the valve body 1 in contact with the valve connecting plate 2, and an annular ring is processed outside the sealing groove 1-1. The unloading groove 1-2 is also processed with a linear unloading groove 1-3 communicating with the atmosphere on the contact surface of the valve body 1 in contact with the valve connecting plate 2, and the annular unloading groove 1-2 is connected with the linear unloading groove. Slots 1-3 are connected. exist figure 1 In the case shown, there are two annular unloading grooves 1-2 communicating with each other, and finally the linear unloading groove 1-3 communicating with the atmosphere is connected.

[0016] When in use, install the sealing ring 3 in the sealing groove 1-1, and connect the valve body 1 with the valve connecting plate 2 through the connecting screw installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com