A dam surface geomembrane anti-seepage rockfill dam, construction method and defect location method

A construction method and geomembrane technology, applied in dams, barrages, sea area engineering, etc., can solve problems such as difficult to locate accurately, achieve the effects of preventing tensile damage, strong adaptability to dam foundation deformation, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

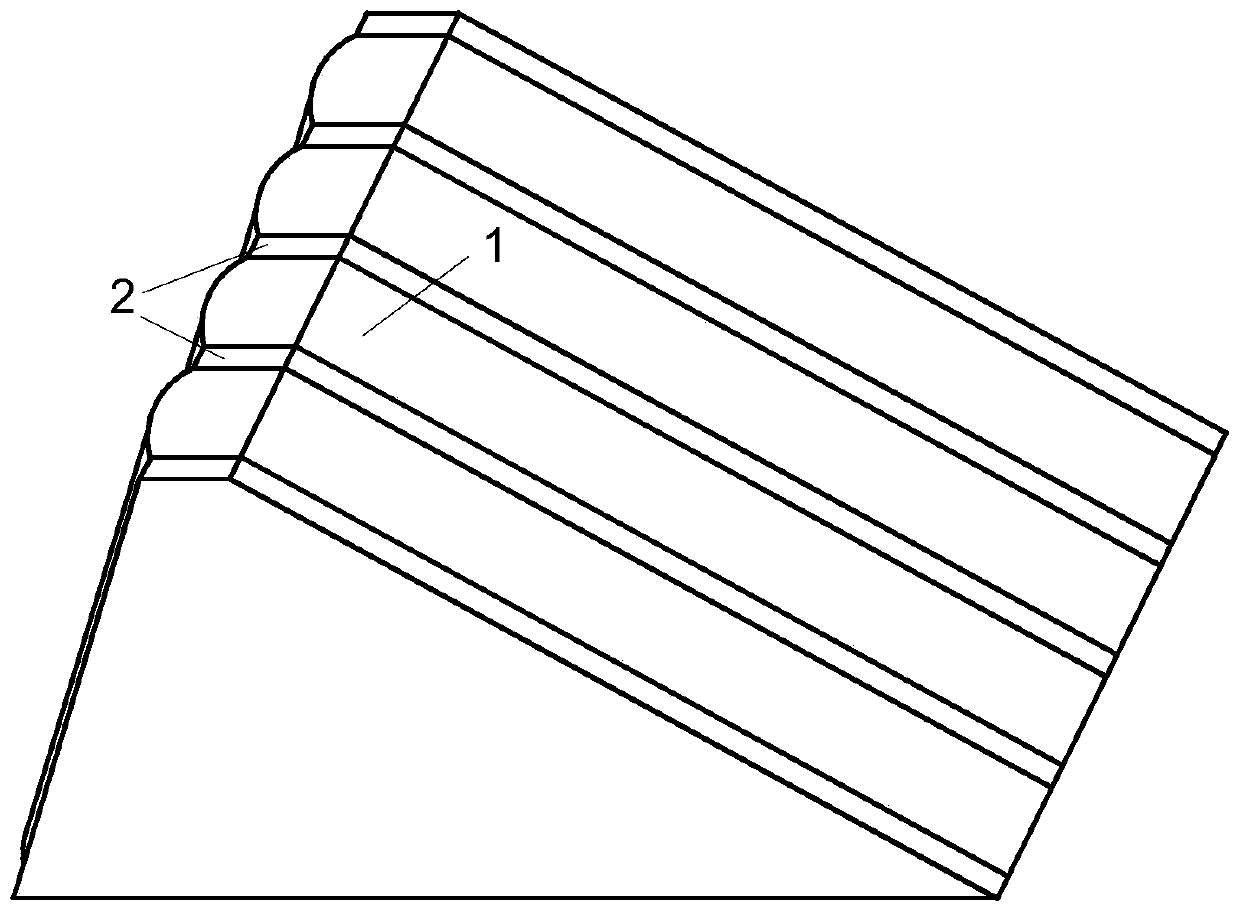

[0054] Such as figure 1 As shown, a dam surface geomembrane anti-seepage rockfill dam includes several independent dam sections 1 arranged sequentially along the axis of the dam body (that is, the length direction), and each independent dam section has a unique number.

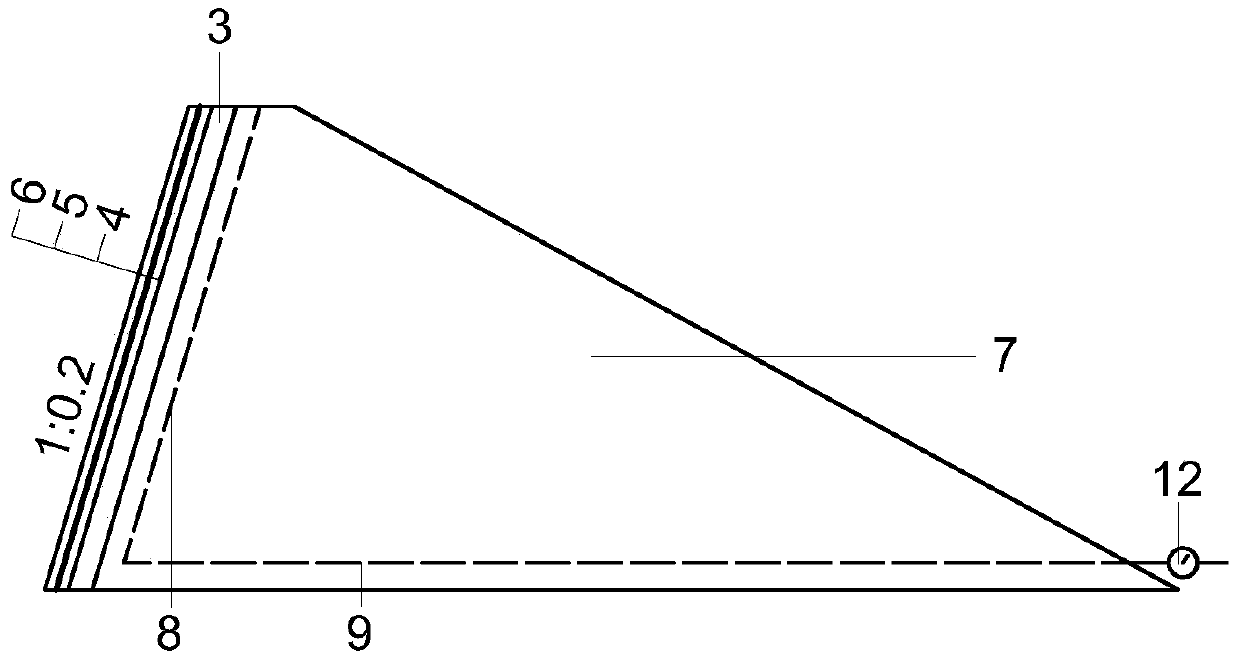

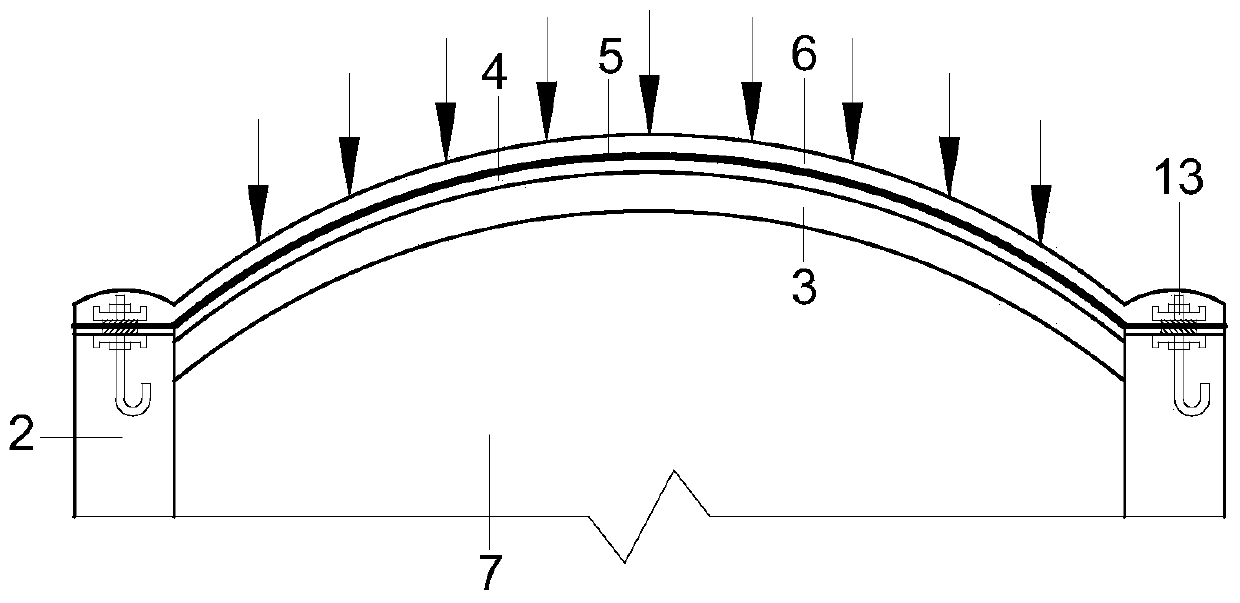

[0055] Each independent dam section includes a buttress 2, a rockfill body 7, an anti-seepage body and a defect leakage monitoring system.

[0056] The buttresses are located on both sides of the rockfill body. Two adjacent independent dam sections share one buttress. The buttresses are all formed by pouring reinforced concrete. The distance between adjacent buttresses is 15-20m.

[0057] The rockfill body is located between adjacent piers and is filled with rockfill materials or sand and gravel materials; the upstream dam slope ratio of the rockfill body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com