Connected groove of silicon material acid plant

A technology of one-piece tank and silicon acid, which is applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of pickling equipment process stability, safety and low work efficiency, and achieve Shorter cycle times, fewer parts, less components and reduced mechanism effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

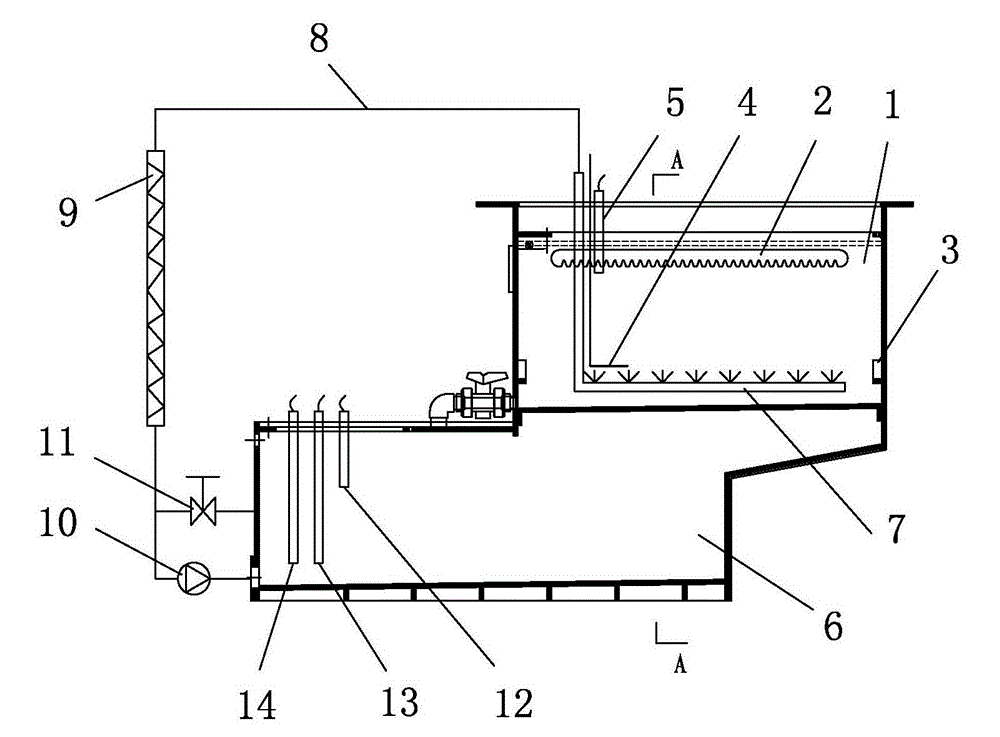

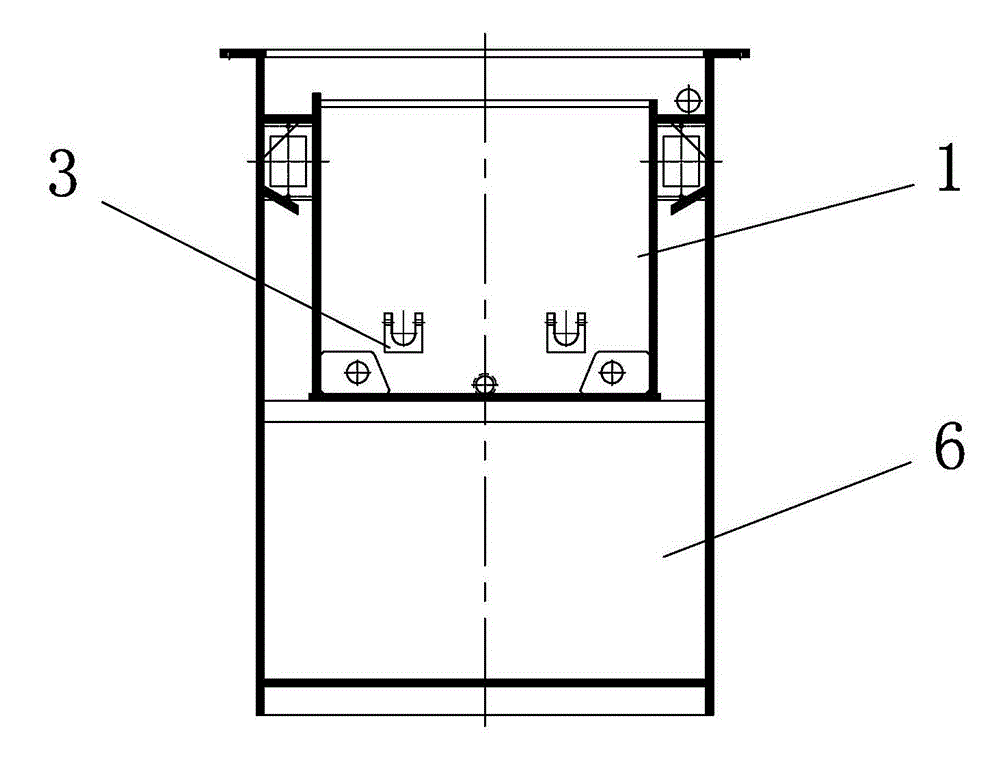

[0018] figure 1 and figure 2 The basic structure of the preferred embodiment of the present invention is shown. The silicon material pickling integrated tank includes a main tank 1, a secondary tank 6 and a tank cover (not shown) connected to an external exhaust system. The main tank 1 is connected to the upper part of the cavity of the auxiliary tank 6 to form an integrated tank body of the main tank and the auxiliary tank. There is a gap between the outer wall of the main tank 1 and the inner wall of the auxiliary tank 6. The upper edge of the main tank is provided with a wavy overflow port 2 (or a rectangular overflow port), and the lower part of the inner cavity of the main tank 1 is provided with a support Block 3. A cooling system that can cool the liquid medicine in the main tank 1 is also communicated between the main tank and the auxiliary tank. In this embodiment, the cooling system includes: an infusion tube 7 arranged at the bottom of the main tank 1, a liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com