Fuel battery apparatus possessing recirculated work fuel

A technology of fuel cells and fuel cell units, applied in the direction of fuel cells, fuel cell additives, transportation fuel cell technology, etc., to eliminate the risk of explosion, improve the overall efficiency, and achieve the effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

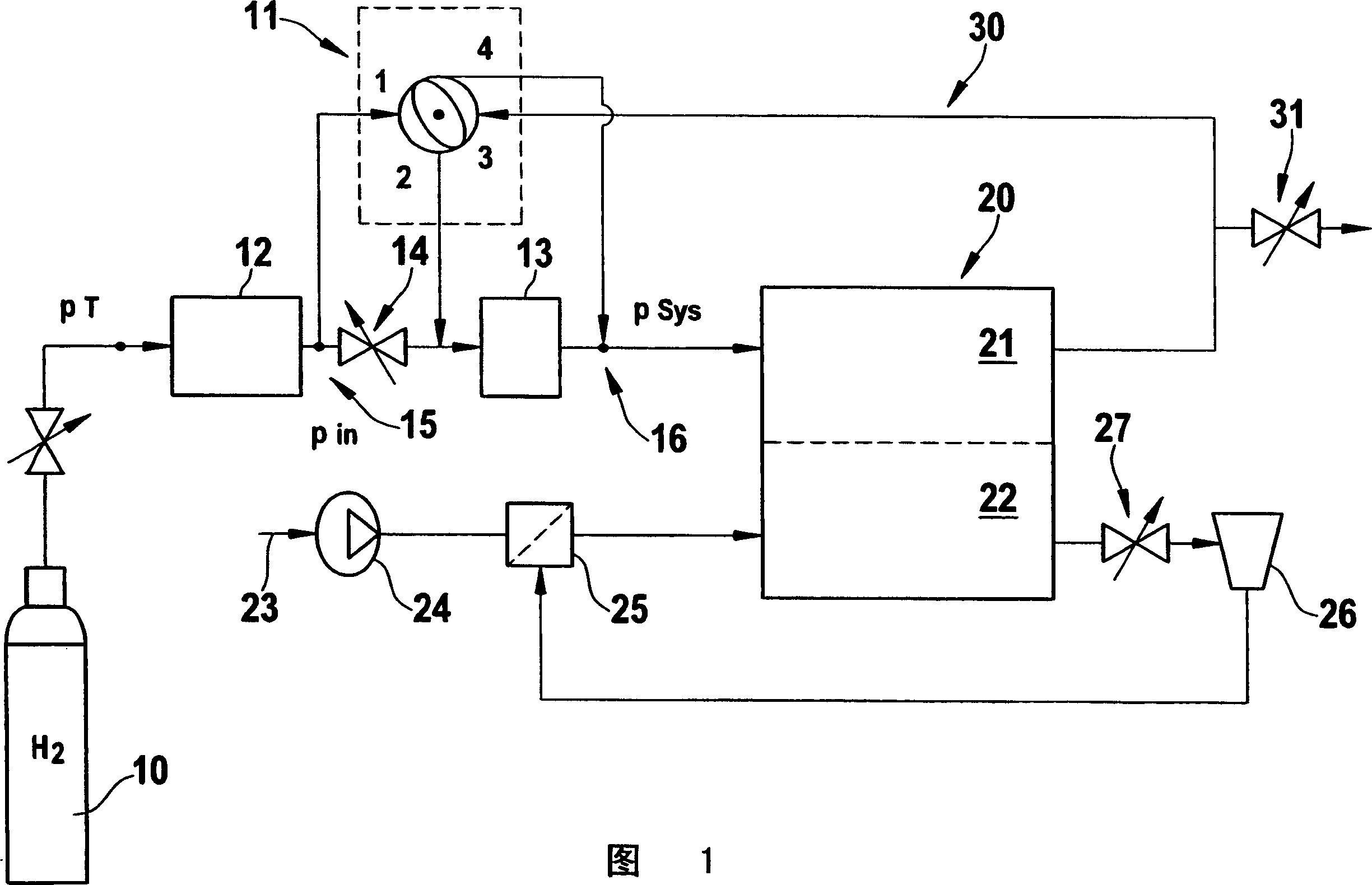

[0030] FIG. 1 schematically shows the basic structure of a fuel cell system with a compressor 11 driven by the high pressure of primary fuel or hydrogen 10 . The primary hydrogen 10 flows into the compressor 11 through a pressure reducing valve 12 using a bore. A compressor 11 is arranged in the flow direction of the hydrogen 10 downstream of a pressure regulator 12 which decompresses the hydrogen 10 from eg 12 bar to eg 9 bar-10 bar (absolute). The initial pressure on bore 1 is reduced to a pressure on bore 2 of eg about 9-10 bar (absolute) on the drive part of a compressor 11 which may also be called a so-called HRB (Hydrogen Recirculation Blower).

[0031] Partially decompressed hydrogen 10 flows from compressor 11 to hydrogen metering unit 13 (HMD: hydrogen metering device).

[0032] Between the pressure regulator 12 and the hydrogen metering unit 13 is provided a bypass 14 comprising an adjustable flow valve 15 (eg valve). Hydrogen 10 can thus be delivered to fuel cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com