System and method for generating chlorine dioxide

A chlorine dioxide and compound technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve the problems of shortened storage period, loss of sealing, foil rupture, etc., and achieve the effect of eliminating the danger of explosion and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0067] Suitable surfactants include those that do not react with or interfere with the release of chlorine dioxide. Anionic surfactants are generally suitable for use in the solid compositions described herein because most of them do not react with or interfere with chlorine dioxide release. Examples include, but are not limited to, SLS (sodium lauryl sulfate), sodium lauryl sulfate, alkyl sulfonates such as 1-pentanesulfonate sodium salt monohydrate, 1-hexanesulfonate sodium salt Monohydrate, 1-heptane sulfonate sodium salt monohydrate, 1-octane sulfonate sodium salt, 1-decane sulfonate sodium salt, sodium dodecyl benzene sulfonate, linear alkyl benzene Sulfonate, sodium alkyl naphthalene sulfonate. Suitable nonionic surfactants include alkyl poly(ethylene oxide) and more specifically polyethylene oxide. Cationic and amphoteric surfactants are also suitable for use in combination with the exemplary embodiments of the invention.

[0068] Other embodiments of CDG compositions s...

Embodiment 1

[0114] Example 1. The CDG composition (in granular form) is prepared and then dried at 90-150°C. Moisture content <1% by weight. The CDG composition contains (wt%):

[0116] Anhydrous sodium bisulfate 40%

[0117] Methyl hydroxypropyl methylcellulose 15%

[0118] Sodium polyacrylate 10%

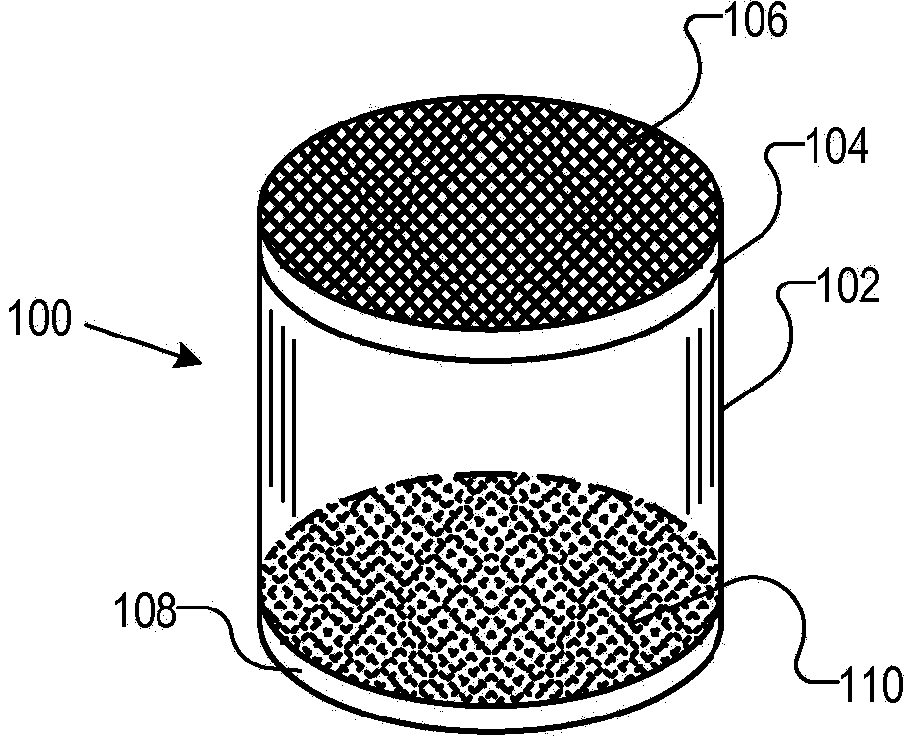

[0119] -Put 2 grams of the CDG composition into the tank 100, and then cap the tank. After putting the tank into 1 liter of water, 190ppm of free ClO is quickly generated in the solution 2 , Measured by an ultraviolet spectrophotometer at 360nm. ClO 2 The pH of the solution was 6.4.

[0120] · Put 2 grams of the CDG composition into the tank 100 inside. After putting the tank into 1 liter of 10% ethanol solution, 172ppm of free ClO is quickly generated in the solution 2 , Measured by an ultraviolet spectrophotometer at 360nm.

[0121] · Put 2 grams of the CDG composition into the tank 100 inside. After putting the tank into 1 liter of 10% isopropyl solution, 160ppm of ...

Embodiment 2

[0124] Example 2. A CDG composition containing an anionic surfactant is prepared and then dried at 90-150°C. The CDG composition contains (wt%):

[0126] Anhydrous sodium bisulfate 40%

[0127] Methylhydroxypropyl methylcellulose 13%

[0128] Sodium polyacrylate 10%

[0129] Sodium Lauryl Sulfate (SLS or SDS) 2%

[0130] -Put 2 grams of the CDG composition into the tank 100, and then cap the tank. After putting the tank into 1 liter of water, it quickly produced 186ppm free ClO 2 The soap-like solution of the product was measured at 360nm by an ultraviolet spectrophotometer. ClO 2 The pH of the solution is 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com