Phosphorus-germanium-zinc polycrystal pressurized synthesis device and synthesis method

A synthesis device and synthesis method technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of low synthesis rate and easy explosion, meet heat dissipation requirements, eliminate the risk of explosion, and facilitate Adjust the effect of the temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

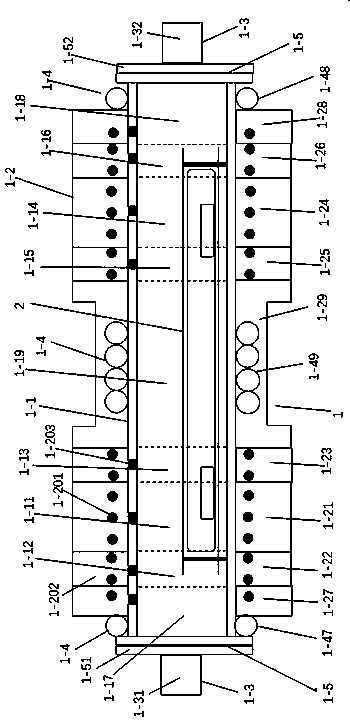

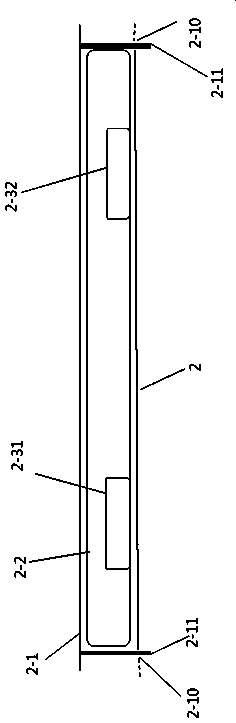

[0023] like figure 1 As shown, a phosphorus-germanium-zinc polycrystalline pressurized synthesis device includes a main furnace body 1 and an ampoule 2, and the main furnace body 1 includes an inner furnace body 1-1, an outer layer heating device 1-2, and an air pressure control device 1-3 , cooling device 1-4, sealing flange 1-5; the inner furnace body 1-1 is a pressure-resistant metal tubular structure, placed horizontally, and the pressure that can withstand is not less than 100atm, and the two sealing flanges 1-5 are respectively Set at both ends of the inner furnace body 1-1, there are two sets of air pressure control devices 1-3, namely the air pressure control device I (1-31) and the air pressure control device II 1-32, and one end of the inner furnace body 1-1 passes through The flange 1-51 is connected to the air pressure control device I (1-31), and the other end is connected to the air pressure device II 1-32 through the flange 1-52; the ampoule 2 is placed in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com