Artificial lift mechanisms

A kind of artificial and component technology, applied in the direction of mechanical equipment, machine/engine, liquid variable displacement machinery, etc., can solve the problem of gas spring counterweight without storage and recirculation, etc., to eliminate the risk of fire or explosion, simplify stockholding, The effect of service time minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

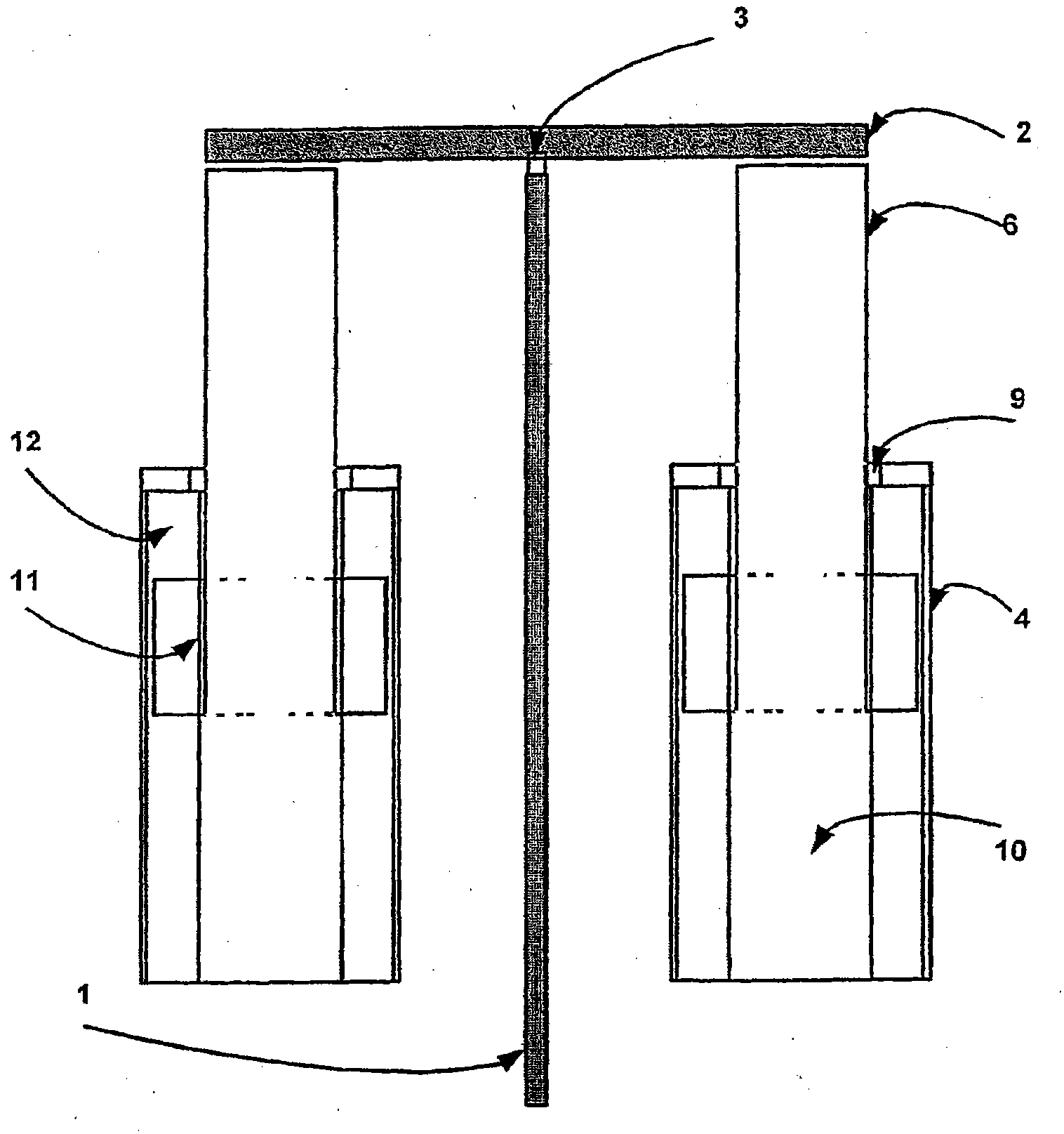

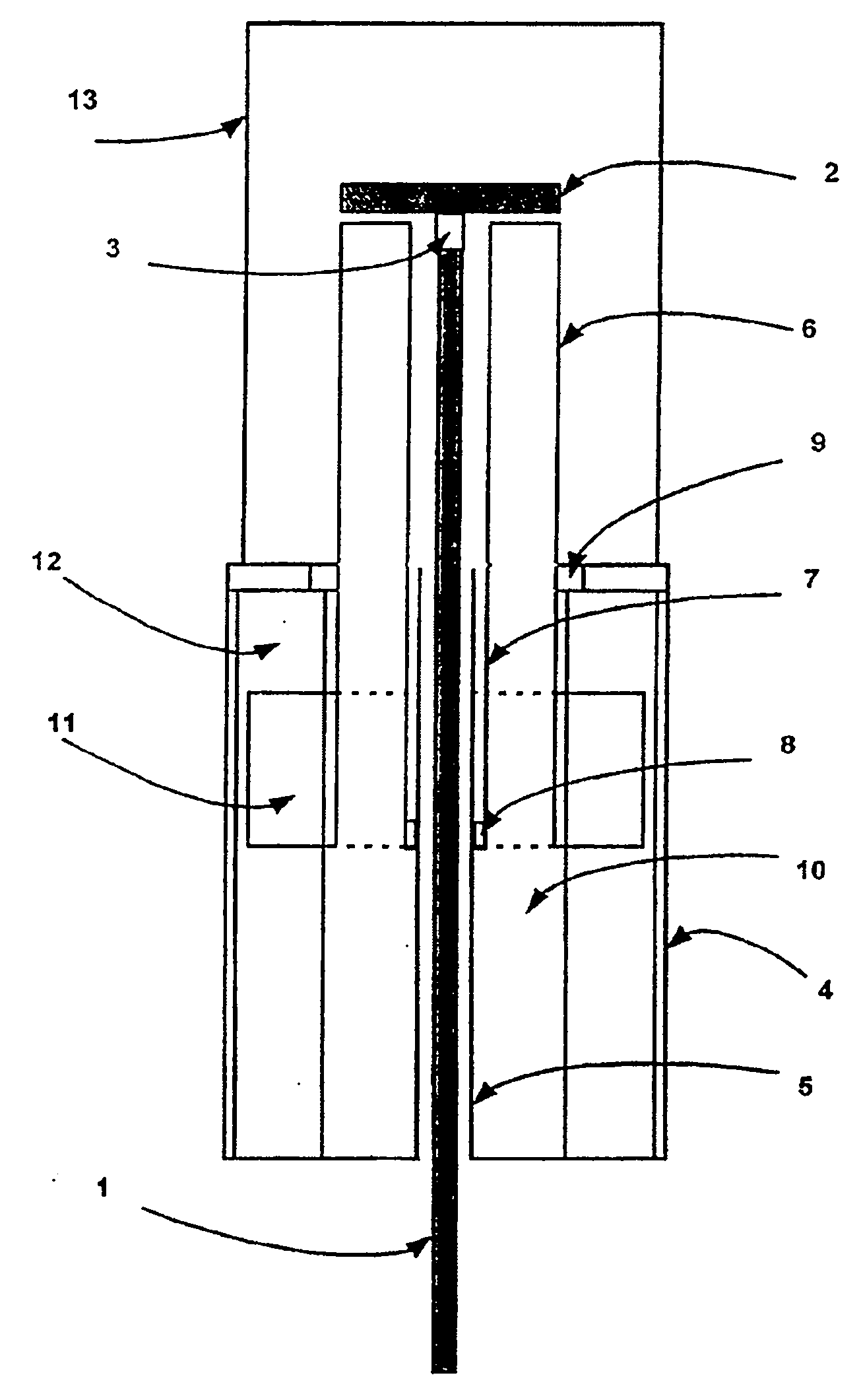

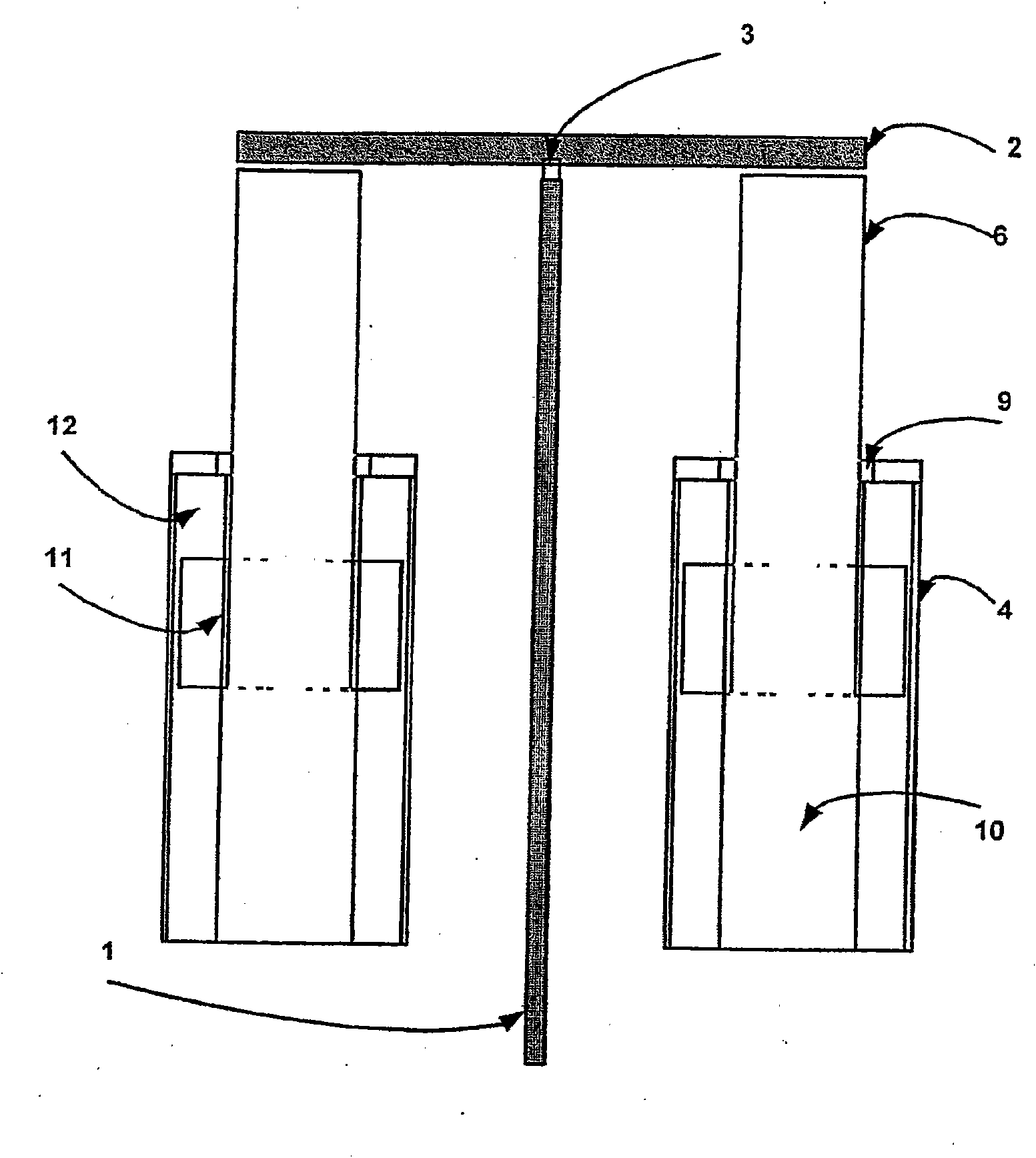

[0058] Referring to Figure 1 , there is shown a longitudinal section view of the basic cylindrical mechanism in which the polished rod 1 of the pumping string is suspended from the disc 2 by a shackle or flexible coupling 3 . Flexible couplings are necessary to accommodate slight tolerances that may exist in alignment or may occur momentarily between the axis of the machine and the direction of the applied force. The rod 1 passes through a cylindrical passage or cavity in the body of the mechanism delimited by the upper tube 7 and the lower tube 5 . The interior of the mechanism is made airtight by a sealed bearing unit 8 located between the coaxial tubes 5 and 7 .

[0059] The mast 1 is raised and lowered by means of an extendable cylinder 6 with a disc 2 attached to the top outer surface of the cylinder. The cylinder 6 extends iteratively from the base body of the machine 4 through the second bearing sealing unit 9 . The position of the cylinder 6 is controlled by the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com