Tire type puncture-proof eccentric packing box

A technology of eccentric disk and packing box, which is applied in wellbore/well parts, earthwork drilling and production, sealing/isolation, etc. It can solve the problems of low utilization rate of packing, poor sealing effect, no elastic deformation, etc., and achieve structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

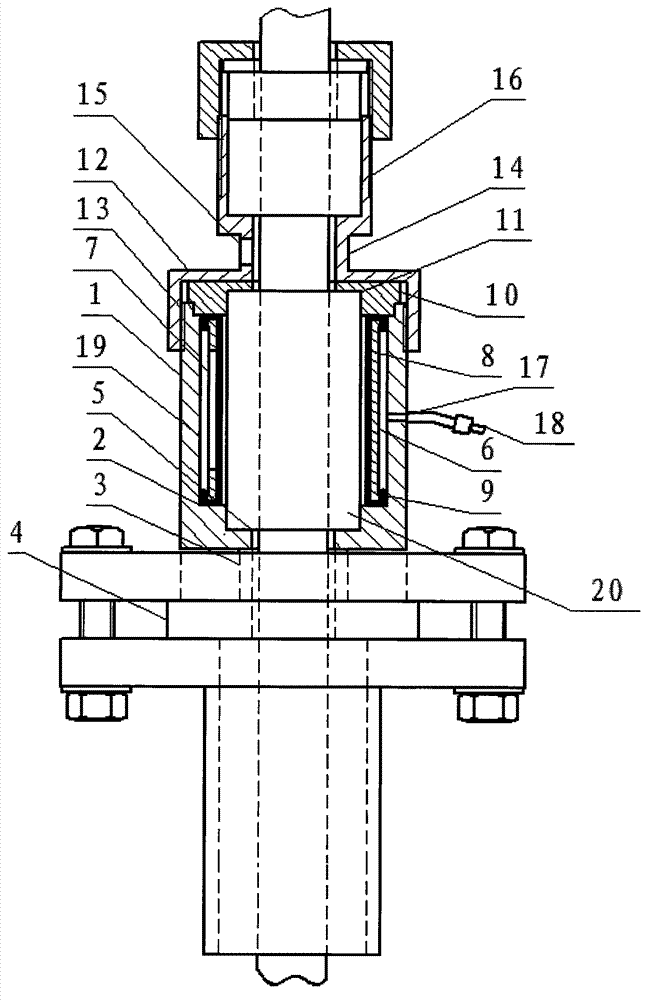

[0009] exist figure 1 Among them, the packing cavity (1) is mainly composed of a section of pipe, and a hole (17) is drilled on the outer wall of the pipe. The outside of the hole (17) is airtightly connected with a tire inflation nozzle (18), and the lower end has a bottom (2 ), forming a cavity (19) for accommodating the tire frame (6) and its tire (8) and packing (20), the middle part of the bottom (2) surface has a concave platform (5), and the lower middle part is connected with a Joint thin tube (3), the lower end of thin tube is connected with the middle plate (4) of eccentric flange again and is connected as a whole, and the hole that polished rod passes is arranged in the center. On the tube wall of the tubular tire frame (6) there is a tubular tire (8) made of oil-resistant rubber with air vents (7) in the middle, and the two ends of the tire (8) are sealing rings (9) which are turned outwards and placed on the tire. On the outer edge of frame (6) two ends, it is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com