Start control method of fast refrigerating and fast heating for direct current variable frequency air conditioner

A technology of DC frequency conversion and control method, which is applied in heating and ventilation control systems, heating methods, lighting and heating equipment, etc., and can solve problems such as inability to achieve rapid cooling and rapid heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

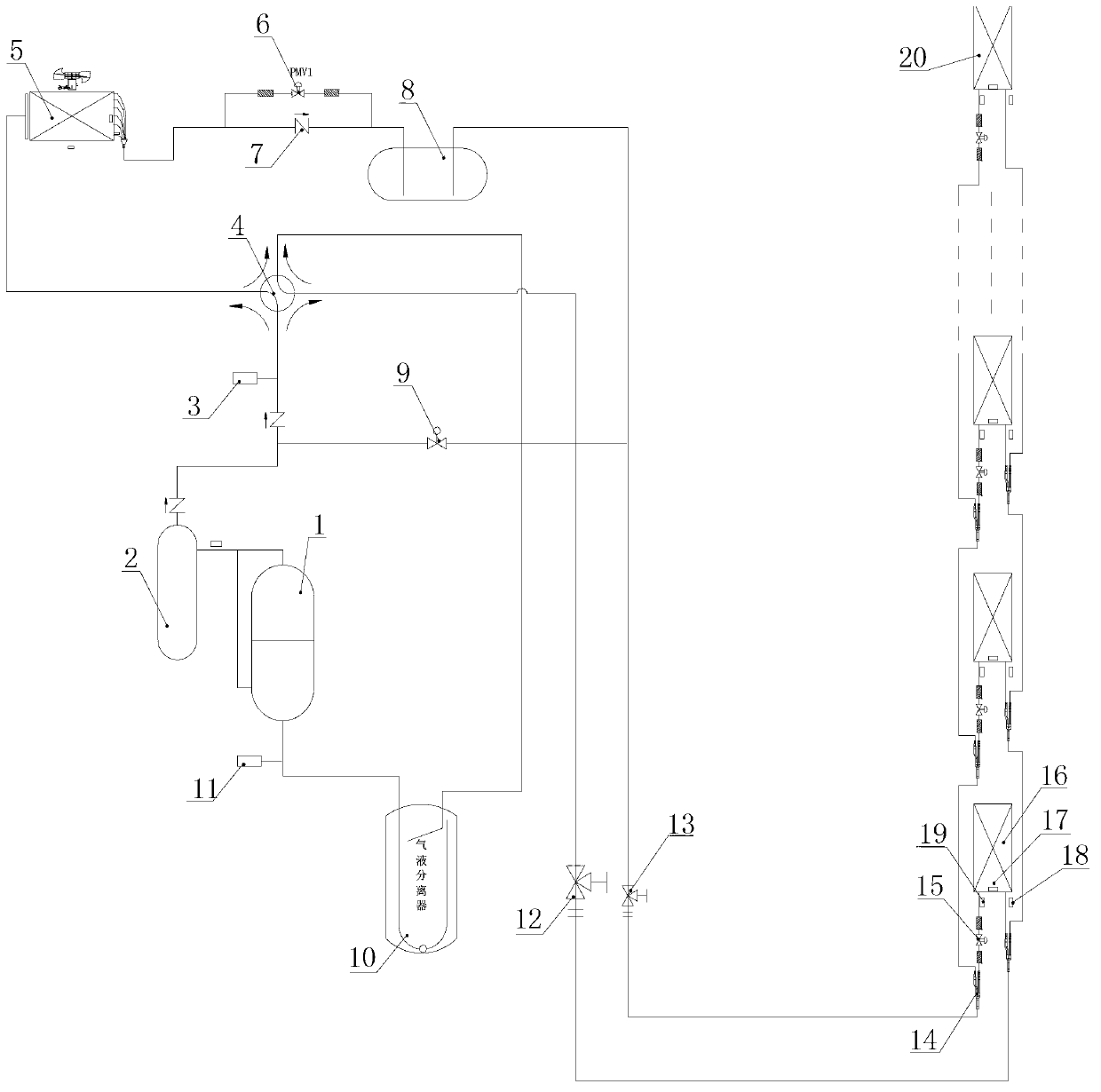

Image

Examples

example 1

[0048] Example 1: Cooling Mode Quick Start Control

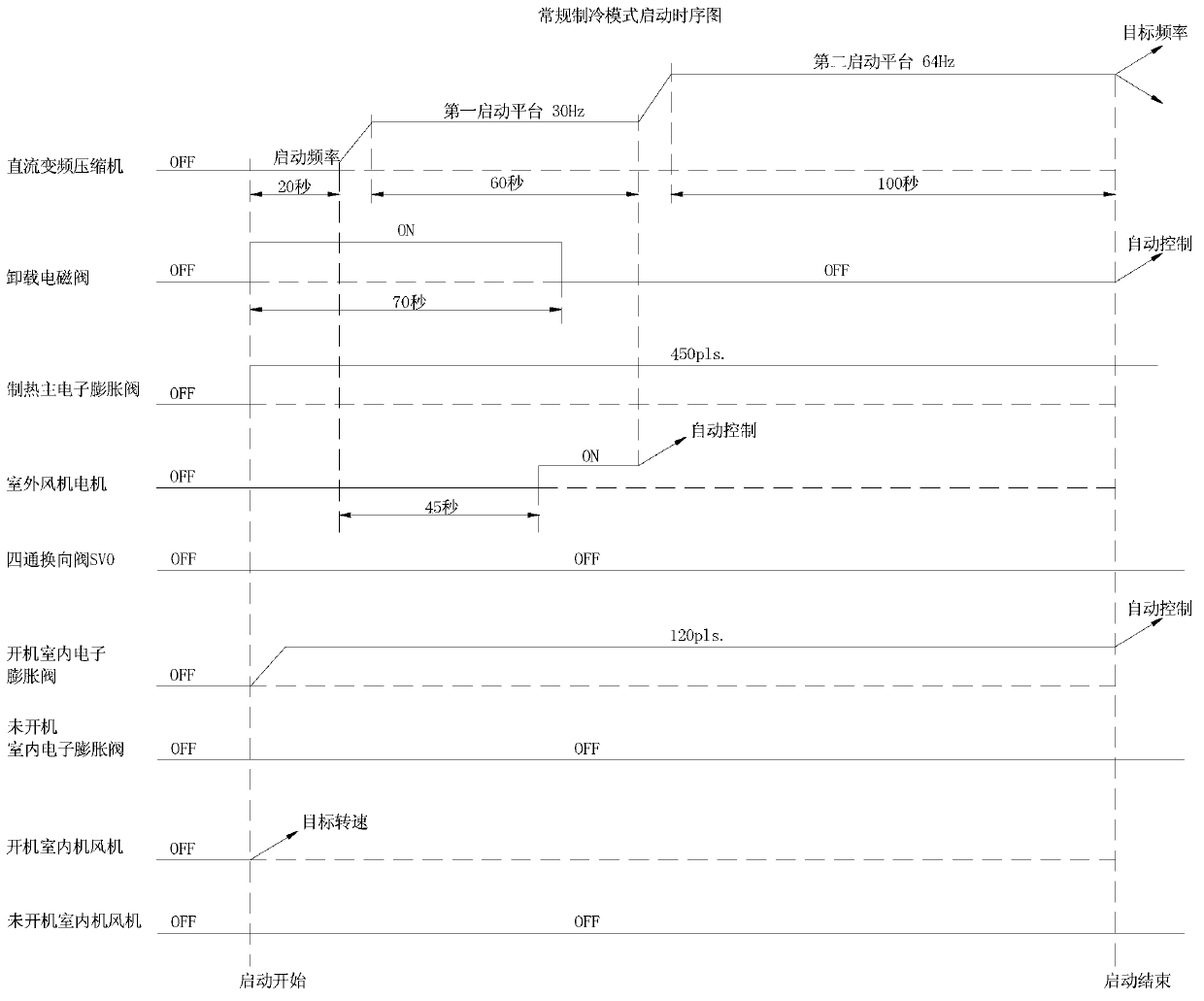

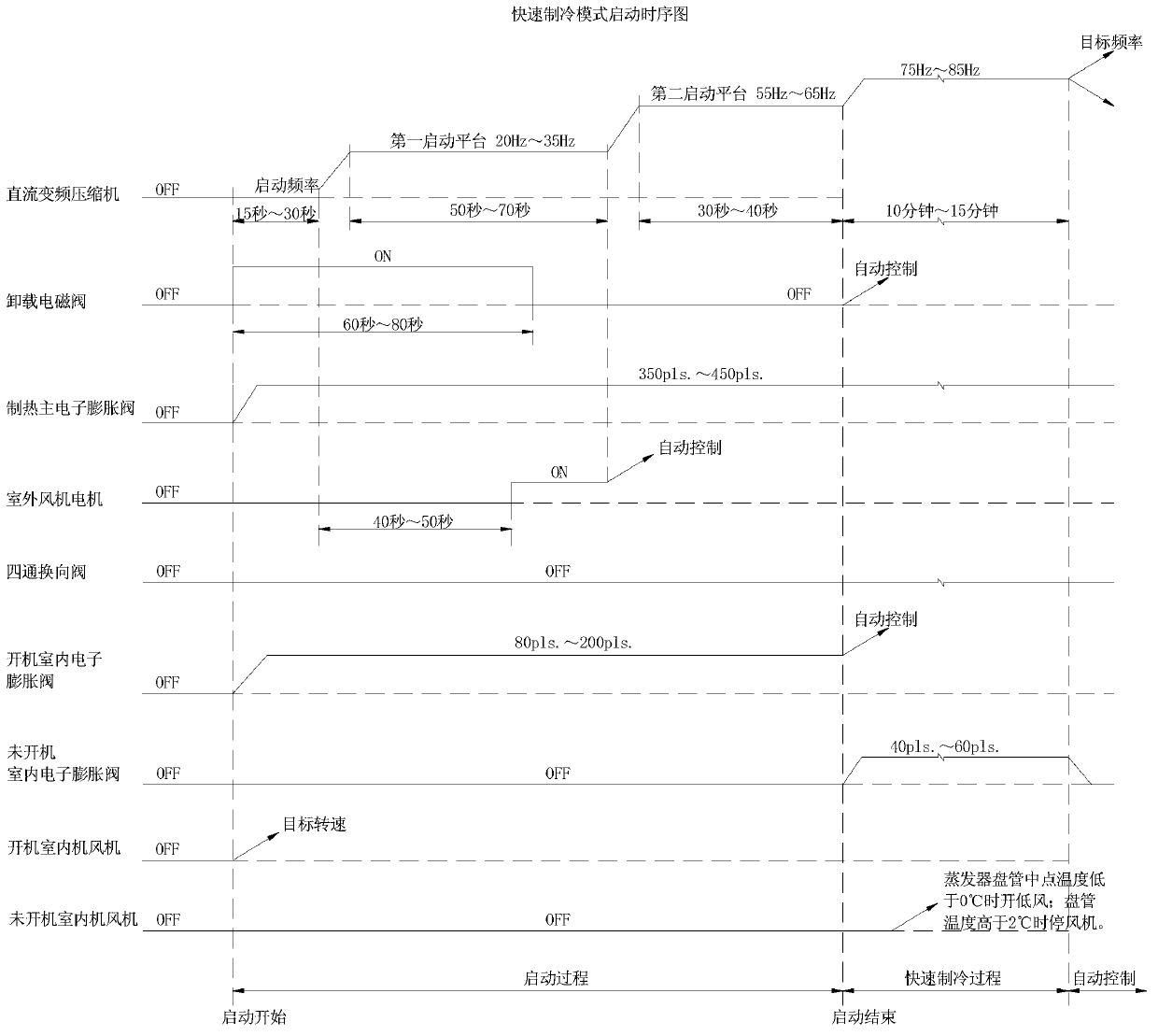

[0049] The timing diagram of quick start control in cooling mode is shown in the appendix image 3 As shown, the control methods of the main control components in the DC inverter air conditioning system are as follows:

[0050] DC inverter compressor control method: When the user sends a start-up command through the remote control, the DC inverter compressor starts to start, and after the first startup platform runs at a frequency of 30Hz for 60 seconds, it transfers to the second startup platform and runs at a frequency of 65Hz for 40 seconds. Enter the rapid cooling process. At this time, the DC inverter compressor operates at a frequency of 85Hz for 10 minutes, and then transfers to the automatic control process, and the DC inverter compressor operates at the calculated target frequency;

[0051] Unloading solenoid valve control method: The unloading solenoid valve is opened in advance 20 seconds before the start of the ...

example 2

[0059] Example 2: Quick start control method in heating mode

[0060] Please refer to the appendix for the timing diagram of quick start control in heating mode Figure 5 As shown, the control methods of the main control components in the DC inverter air conditioning system are as follows:

[0061] DC inverter compressor control method: When the user sends a start-up command through the remote control, the DC inverter compressor starts to start, and after the first startup platform runs at a frequency of 30Hz for 60 seconds, it transfers to the second startup platform and runs at a frequency of 65Hz for 40 seconds. Enter the rapid heating process. At this time, the DC inverter compressor operates at a frequency of 85Hz for 10 minutes, and then transfers to the automatic control process, and the DC inverter compressor operates at the calculated target frequency;

[0062] Unloading solenoid valve control method: The unloading solenoid valve is opened in advance 20 seconds befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com