Operation workshop bottleneck identification method taking machine attribute as interval number

A feature attribute and job shop technology, applied in data processing applications, predictions, calculations, etc., can solve problems such as inability to comprehensively judge and identify bottleneck equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

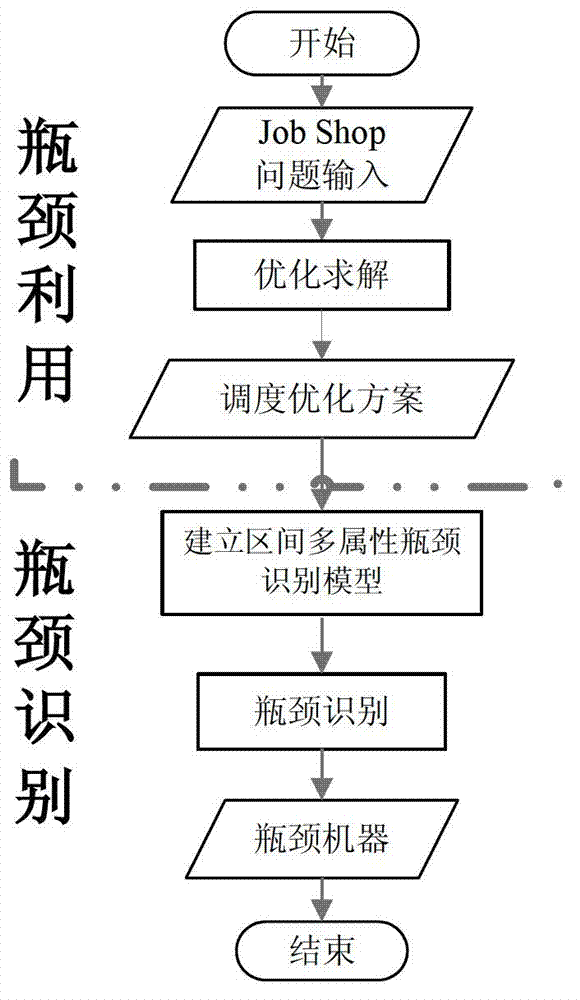

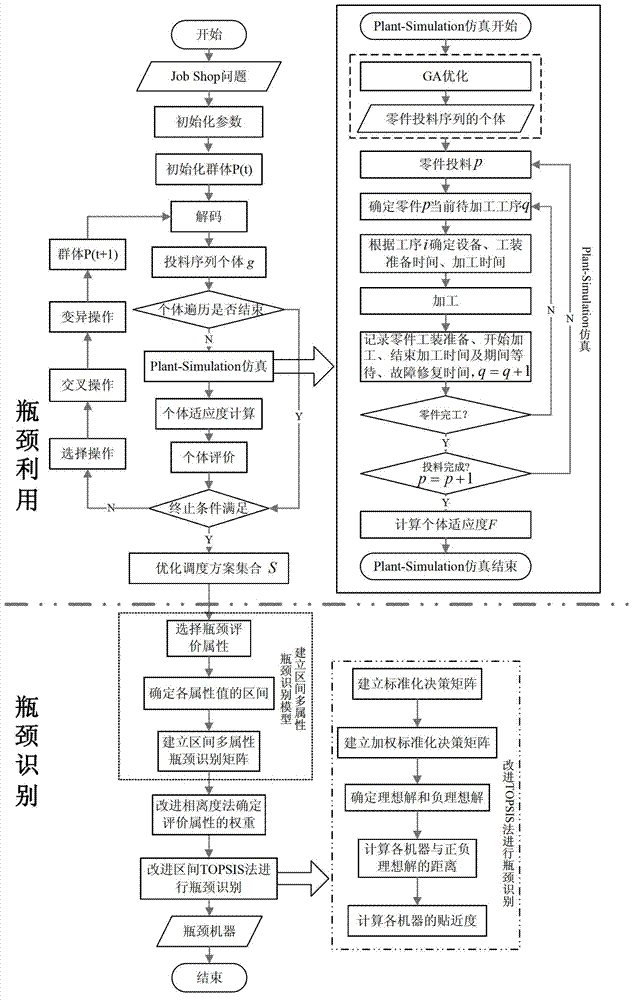

Method used

Image

Examples

Embodiment Construction

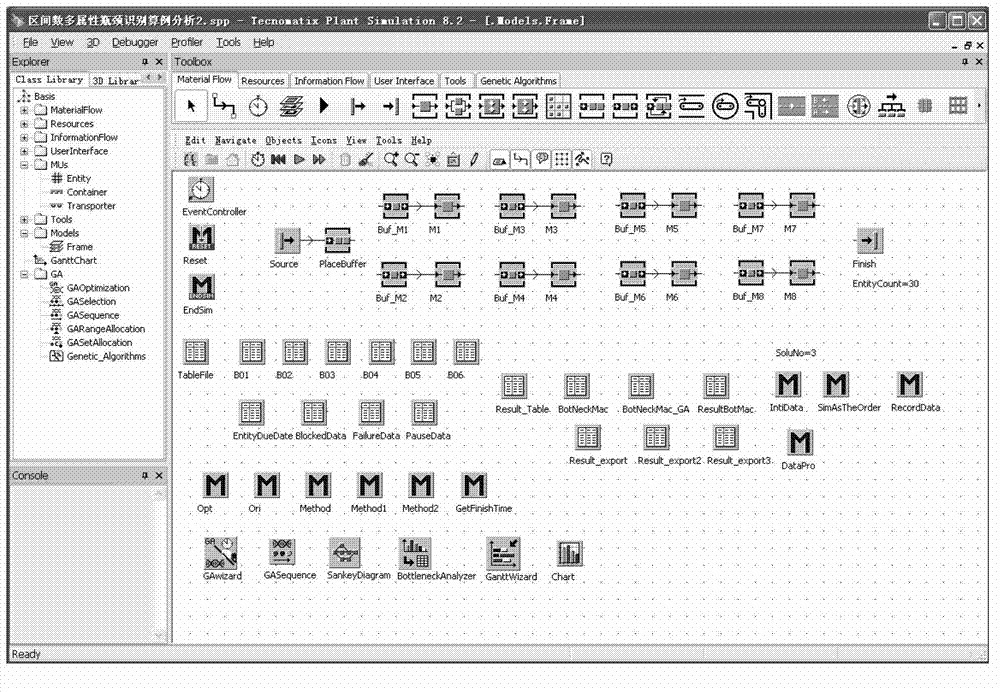

[0045] Describe the present invention below in conjunction with specific embodiment:

[0046] In this embodiment, bottleneck identification is performed on a production system of 30 six types of workpieces (W1-W6) and 8 machines (M1-M8) in a processing workshop. The working time, failure rate, Mean Time to Repair (MTTR) and processing cost per unit time of the machine are shown in Table 1; the processing route, unit price and delivery date of the workpiece are shown in Table 2; the processing hours information is shown in Table 3.

[0047] Table 1 machine related parameters

[0048]

[0049] Table 2 Workpiece related parameters

[0050]

[0051] Table 3 Working hours information table

[0052]

[0053] In this embodiment, the mobile bottleneck identification method (SBD method) is adopted, and the literature "Research on Job Shop Bottleneck Identification Method under Disturbance Environment" (Wang Gang, Wang Junqiang, Sun Shudong, Mechanical Science and Technology, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com