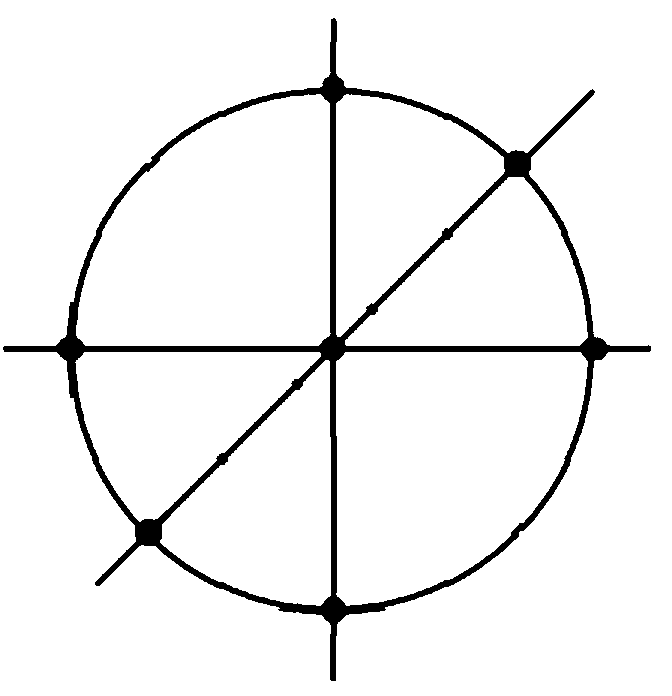

Novel camera calibration method based on two crossed straight lines

A camera calibration, straight line technology, applied in image data processing, instruments, calculations, etc., can solve problems such as complex calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail through several aspects of feasibility analysis, simulation experiment and real camera experiment.

[0038] One, feasibility analysis of the present invention:

[0039] 1.1 Explanation of the symbols used below: the three-dimensional point M in the camera coordinate system is expressed as (X, Y, Z), and M represents the vector corresponding to M, that is, the bold body of the symbol used in this paper represents a vector or matrix, and its corresponding image pixel is m =(x,y), its homogeneous coordinates are expressed as The present invention uses a standard pinhole camera model, and the parameter matrix is represented by K. M and have the following relationship

[0040] Z m ~ = KM K = α γ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com