Silver-carrying porous glass filteration material and preparation method thereof

A porous glass and silver-carrying technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low specific surface area of silver material and environmental pollution by waste liquid, and achieve simple and convenient process and low silver consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Execute step S11: provide glass foaming powder, the particle size of the glass foaming powder is 2 microns;

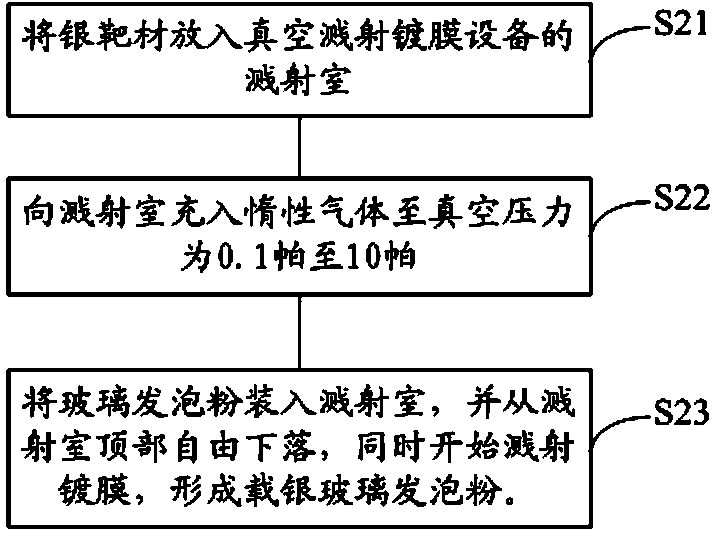

[0029] Execute step S12: plate a silver layer on the surface of the glass foam powder to form silver-loaded glass foam powder. Specific process such as figure 2 As shown: execute step S21, put the silver target into the sputtering chamber of the vacuum sputtering coating equipment; execute step S22, fill the sputtering chamber with an inert gas until the vacuum pressure is 0.1 Pa to 10 Pa; execute step S23, put The glass foaming powder is loaded into the sputtering chamber, and falls freely from the top of the sputtering chamber, and at the same time starts sputtering coating to form silver-loaded glass foaming powder.

[0030] Wherein, in step S22, the sputtering chamber is first evacuated to 9×10 -3 Pa, and then filled with argon to a vacuum pressure of 0.1 Pa;

[0031] In step S23, the glass foaming powder is loaded into the hopper, and the hopper is rota...

Embodiment 2

[0037] As described in Embodiment 1, step S11 to step S15 and step S21 to step S23 are performed, wherein the particle size of the glass foaming powder is 3 microns, filled with argon until the vacuum pressure is 0.5 Pa, and the sputtering current is 15 amperes; The heating temperature of the high-temperature heating furnace is 850°C, and the heating time is 10 minutes.

[0038] The composition of the silver-loaded porous glass filter material prepared by the above process is as follows: SiO 2 : 69.87%, Al 2 o 3 : 2.22%, Na 2 O: 11.92%, CaO: 10.91%, K 2 O: 1.02%, Ag: 0.8%, pore size 0.1~0.4mm, dry density: 0.3g / cm 3 .

Embodiment 3

[0040] As described in Embodiment 1, step S11 to step S15 and step S21 to step S23 are performed, wherein the particle size of the glass foaming powder is 4 microns, filled with argon until the vacuum pressure is 0.5 Pa, and the sputtering current is 20 amperes; The heating temperature of the high-temperature heating furnace is 700°C, and the heating time is 20 minutes.

[0041] The composition of the silver-loaded porous glass filter material prepared by the above process is as follows: SiO 2 : 69.87%, Al 2 o 3 : 2.22%, Na 2 O: 11.92%, CaO: 10.91%, K 2 O: 1.02%, Ag 1.2%, pore size 0.2~0.6mm, dry density: 0.3g / cm 3 .

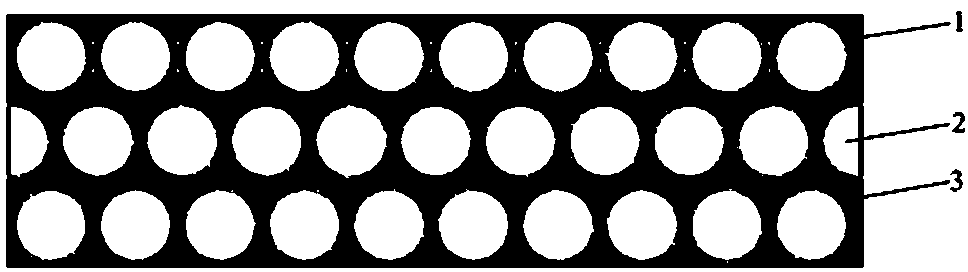

[0042] image 3 Schematic diagram of the silver-loaded porous glass filter material prepared in the embodiment of the present invention. Such as image 3 As shown, in the silver-loaded porous glass filter material, the silver layer 1 is attached to the inner surface of the hole 2 produced in the glass 3 .

[0043] Figure 4a Electron micrograph of a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap