Multielement-doped strontium phosphate luminescent film, and preparation method and applications thereof

A strontium phosphate, multi-element technology, applied in electrical components, vacuum evaporation plating, coating, etc., can solve problems such as narrow wavelength range and poor film quality, achieve wide luminous range, good film adhesion, and realize large The effect of area deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

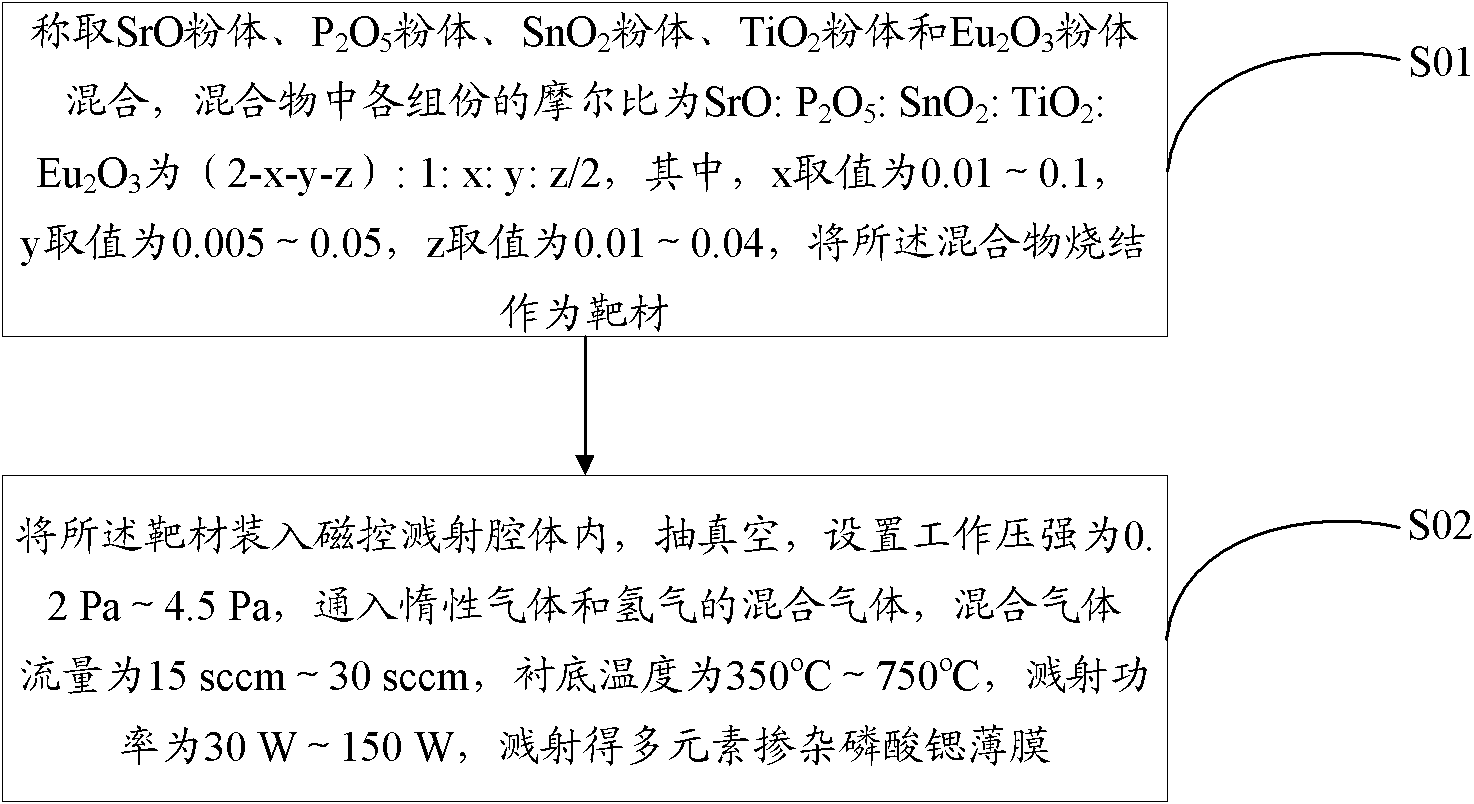

[0017] Another purpose of the embodiment of the present invention is to provide a method for preparing the multi-element doped strontium phosphate thin film of the embodiment of the present invention, please refer to figure 1 , which includes the following steps:

[0018] S01: Weigh SrO powder, P 2 o 5 Powder, SnO 2 Powder, TiO 2 Powder and Eu 2 o 3 The powders are mixed, and the molar ratio of each component in the mixture is SrO:P 2 o 5 :SnO 2 :TiO 2 :Eu 2 o 3 (2-x-y-z): 1: x: y: z / 2, wherein, the value of x is 0.01 to 0.1, the value of y is 0.005 to 0.05, and the value of z is 0.01 to 0.04, and the mixture is sintered as the target material;

[0019] S02: Put the target material into the magnetron sputtering chamber, vacuumize, set the working pressure to 0.2Pa-4.5Pa, feed the mixed gas of inert gas and hydrogen, the flow rate of the mixed gas is 15sccm-30sccm, the substrate temperature The temperature is 350°C-750°C, the sputtering power is 30W-200W, and the m...

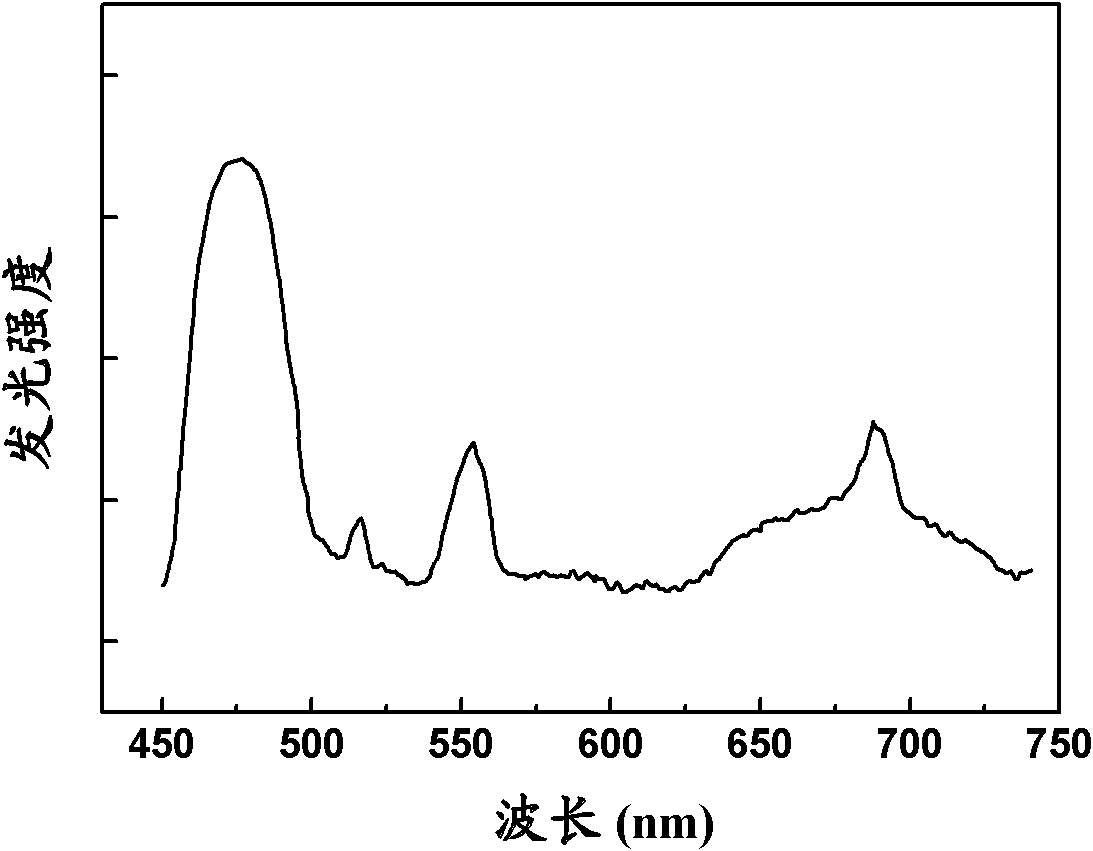

Embodiment 1

[0026] SrO powder with a purity of 99.99%, P 2 o 5 Powder, SnO 2 Powder, TiO 2 Powder and Eu 2 o 3 The powders are mixed, and the molar ratio of each component in the mixture is SrO:P 2 o 5 :SnO 2 :TiO 2 ;Eu 2 o 3 is 1.89:1:0.05:0.02:0.01, the mass of SrO powder is 195.8g, P 2 o 5 The mass of powder is 142g, SnO 2 The mass of the powder is 3g, TiO 2 The mass of the powder is 1.6g, Eu 2 o 3 The mass of the powder is 3.52g. After uniform mixing, high temperature sintering at 1200°C to form a Φ50×2mm ceramic target, and put the target into a vacuum cavity. The sapphire substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, then etched with concentrated phosphoric acid, rinsed with deionized water, finally dried with high-temperature nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate was set to 70mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity t...

Embodiment 2

[0028] SrO powder with a purity of 99.99%, P 2 o 5 Powder, SnO 2 Powder, TiO 2 Powder and Eu 2 o 3 The powders are mixed, and the molar ratio of each component in the mixture is SrO:P 2 o 5 :SnO 2 :TiO 2 ;Eu 2 o 3 is 1.81:1:0.1:0.05:0.02, wherein the mass of SrO powder is 187.5g, P 2 o 5 The mass of powder is 142g, SnO 2 The mass of the powder is 6g, TiO 2 The mass of the powder is 4g, Eu 2 o 3 The mass of the powder is 7.04g. After uniform mixing, high temperature sintering at 1200°C to form a Φ50×2mm ceramic target, and put the target into a vacuum chamber. The sapphire substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, then etched with concentrated phosphoric acid, rinsed with deionized water, finally dried with high-temperature nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate was set to 70mm. Use a mechanical pump and a molecular pump to pump the vacuum of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com