LED (light emitting diode) ceiling lamp

A technology of LED ceiling lamps and LED light sources, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, point light sources, etc. High utilization rate, simple and beautiful appearance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

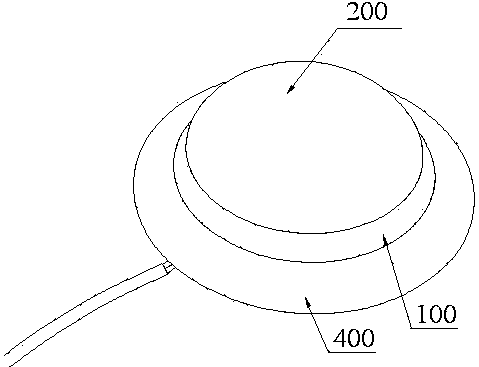

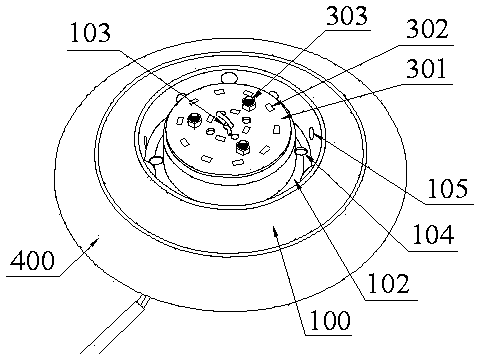

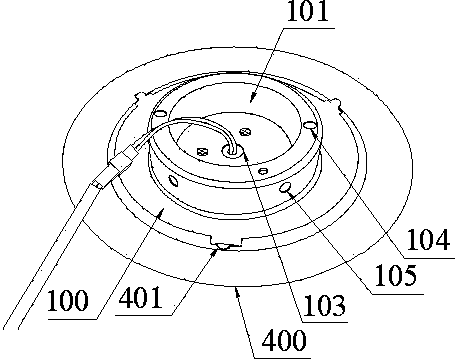

[0022] refer to Figure 1 to Figure 3 , an embodiment of an LED ceiling lamp of the present invention is proposed, including a chassis 100, an LED light source assembly disposed on the chassis 100, a driving device electrically connected to the LED light source assembly, and a light-transmitting cover disposed on the LED light source assembly 200.

[0023] A cavity 101 extending from the center of the back of the chassis 100 can accommodate the drive device and wires. The drive device and wires are accommodated inside the cavity 101 so that they will not be exposed. After the entire lamp is installed, it cannot be seen from the outside. The driving device and wires have a simple and beautiful appearance.

[0024] An LED light source assembly is installed and fixed on the front of the concave cavity 101 , and the LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com