Mechanical push-pull flexible shaft

A push-pull flexible shaft and mechanical technology, applied in the direction of flexible shafts, mechanical equipment, shafts, etc., can solve the problems of reducing the rigidity of the cable core, breaking the shaft core, reducing the bearing capacity of the cable core, etc., to reduce the contact area and small frictional resistance , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

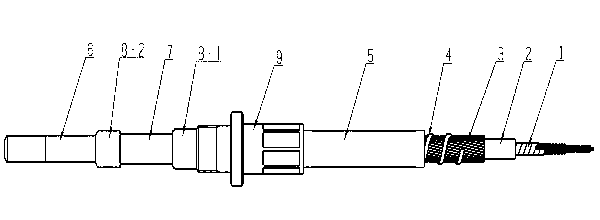

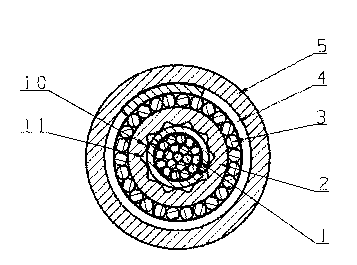

[0028] A mechanical push-pull flexible shaft, the flexible shaft has a smooth flexible shaft core 1, the surface of the flexible shaft core 1 is wrapped with a layer of conduit 2, and several arc-shaped ribs 10 are arranged around the inner hole of the conduit 2, and the outer surface of the conduit 2 is The surface is provided with a straight wire tube 3, the outer surface of the straight wire tube 3 has a layer of spiral belt protective layer 4, the outer surface of the spiral belt protective layer 4 is wrapped with a plastic layer 5, and the two ends of the mechanical push-pull flexible shaft are installed with pipe joints 9. Guide sleeve 7, push-pull rod 6, first seal 8-1 and second seal 8-2.

[0029] The flexible shaft core 1 is composed of a plurality of multi-layer parallel-strand steel wire ropes wrapped and pressed by two flat steel belts to make it solid overall, with a straight and smooth surface, good elasticity, rigidity and flexibility.

[0030] Several arc-shape...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap