dual clutch transmission

A technology of dual-clutch transmission and speed change mechanism, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of unfavorable structural layout design of automobiles, large axial size of transmission, and large space occupation. Flexible structural layout design, reducing production costs, and reducing the effect of axial and radial dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

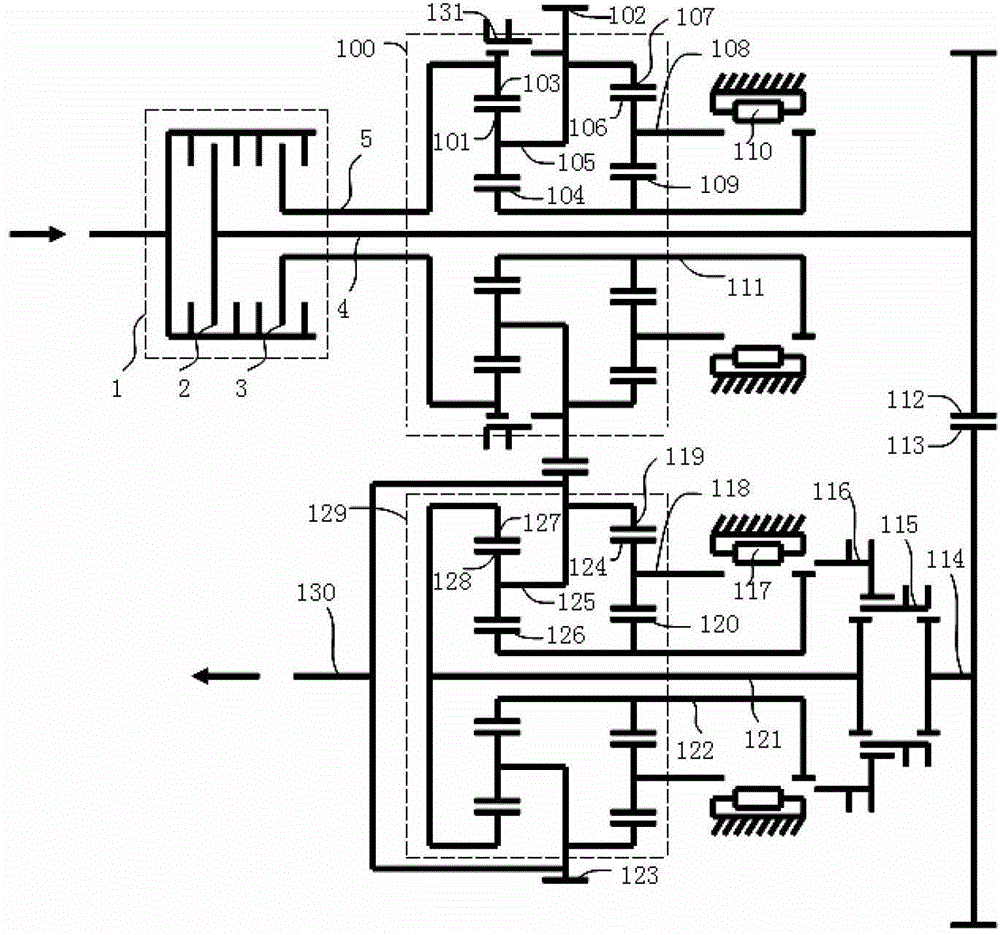

[0056] see Figure 1 to Figure 8 , the dual clutch of the present invention includes a dual clutch assembly 1 (comprising a first clutch 2 and a second clutch 3, a first input shaft 4 and a second input shaft 5 corresponding to the two clutches respectively, a first double-row planetary gear train 100, a second Two double-row planetary gear trains 129, an output shaft 130 and multiple synchronizers. The first double-row planetary gear train and the second double-row planetary gear train are arranged up and down, both of which are Simpson gear transmission mechanisms. The double-row planetary gear train includes two single-row planetary gear mechanisms at the front and rear. The front sun gear 104 and the rear sun gear 109 of the first double-row planetary gear train mesh with the front planetary gear 101 and the rear planetary gear 106 respectively. The gear train is connected to the second clutch 3 through the second input shaft 5, the second input shaft 5 is sleeved on the f...

no. 2 example

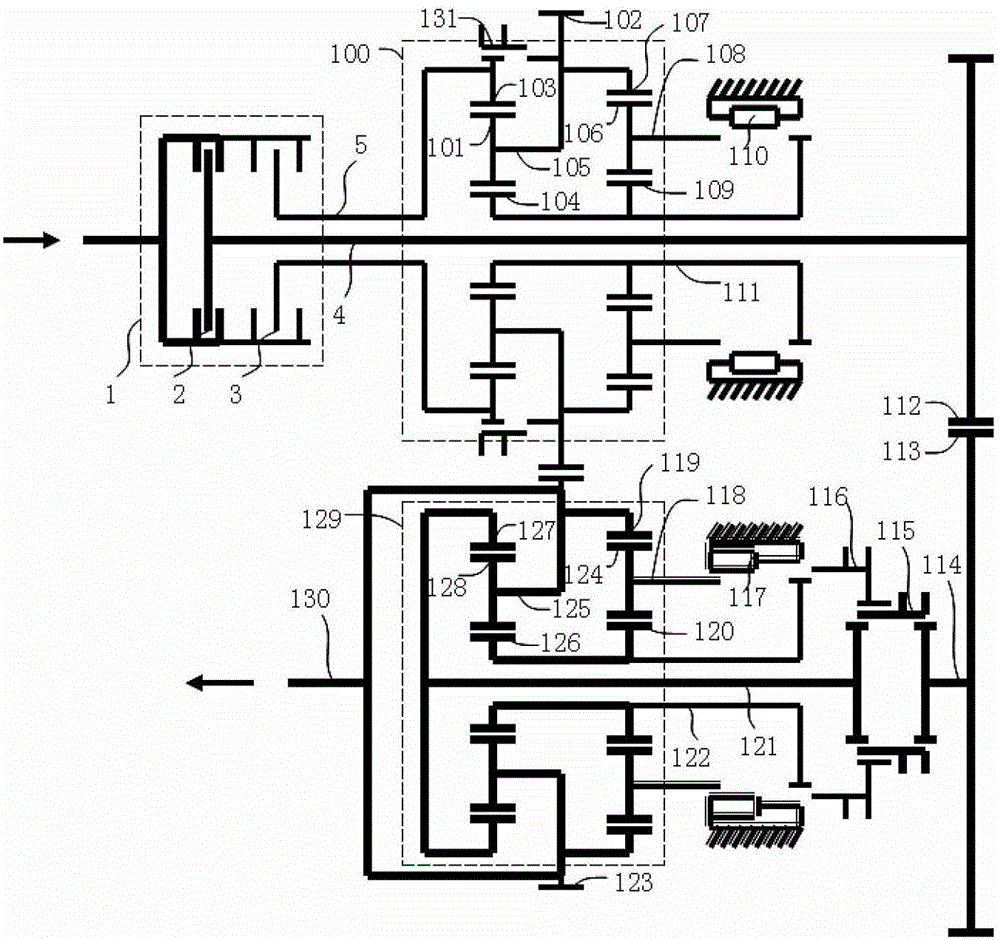

[0072] see Figure 9 , the output shaft is coaxial with the first double-row planetary gear train. The first double-row planetary gear train and the second double-row planetary gear train are both Simpson gear transmission mechanisms. The first double-row planetary gear train and the second double-row planetary gear train are arranged on the right side of each synchronizer, and the output shaft is fixed. On the first gear, the third and fourth gears are arranged on the left side of each synchronizer, and the third gear is fixedly connected with the second input shaft.

[0073] A sixth-speed synchronizer is arranged between the first input shaft 4 and the first sleeve, and the first synchronizer (second and fourth-speed synchronizer 110) is arranged between the front planet carrier 105 and the first shaft in the first double-row planetary gear train. Between sets of 111. The second synchronizer (first and third gear synchronizer 117 ) is arranged between the front planetary c...

no. 3 example

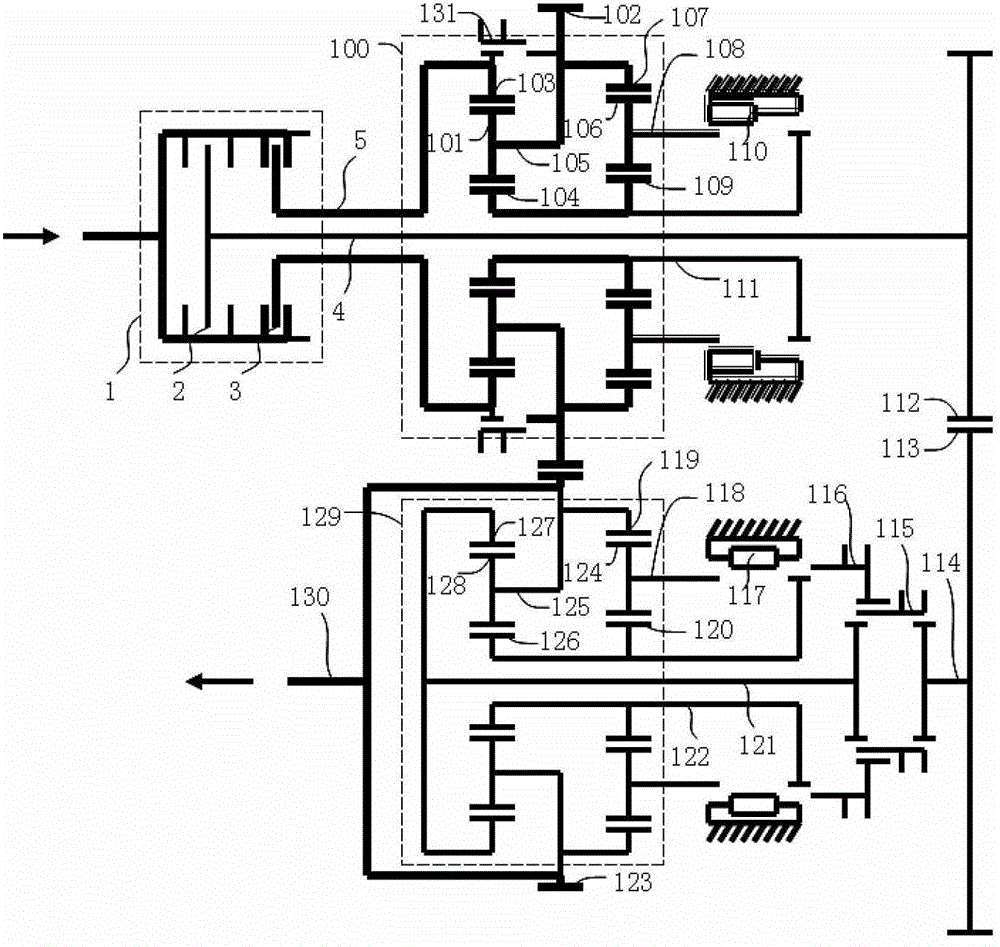

[0076] see Figure 10 , the output shaft is coaxial with the second double-row planetary gear train. The first double-row planetary gear train and the second double-row planetary gear train are both Simpson gear transmission mechanisms. The first double-row planetary gear train and the second double-row planetary gear train are arranged on the right side of each synchronizer, and the output shaft is fixed. On the second gear, the third and fourth gears are arranged on the left side of each synchronizer, and the third gear is fixedly connected with the second input shaft.

[0077] A sixth-speed synchronizer is arranged between the first input shaft 4 and the first sleeve, and the first synchronizer (second and fourth-speed synchronizer 110) is arranged between the front planet carrier 105 and the first shaft in the first double-row planetary gear train. Between sets of 111. The second synchronizer (first and third gear synchronizer 117 ) is arranged between the front planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com