Division and convergent current type multiple-shift automatic transmission system

A technology of automatic shifting and sub-convergence, which is applied in the direction of transmission, gear transmission, transmission control, etc., to achieve power shifting performance, improve power and fuel economy, and facilitate processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

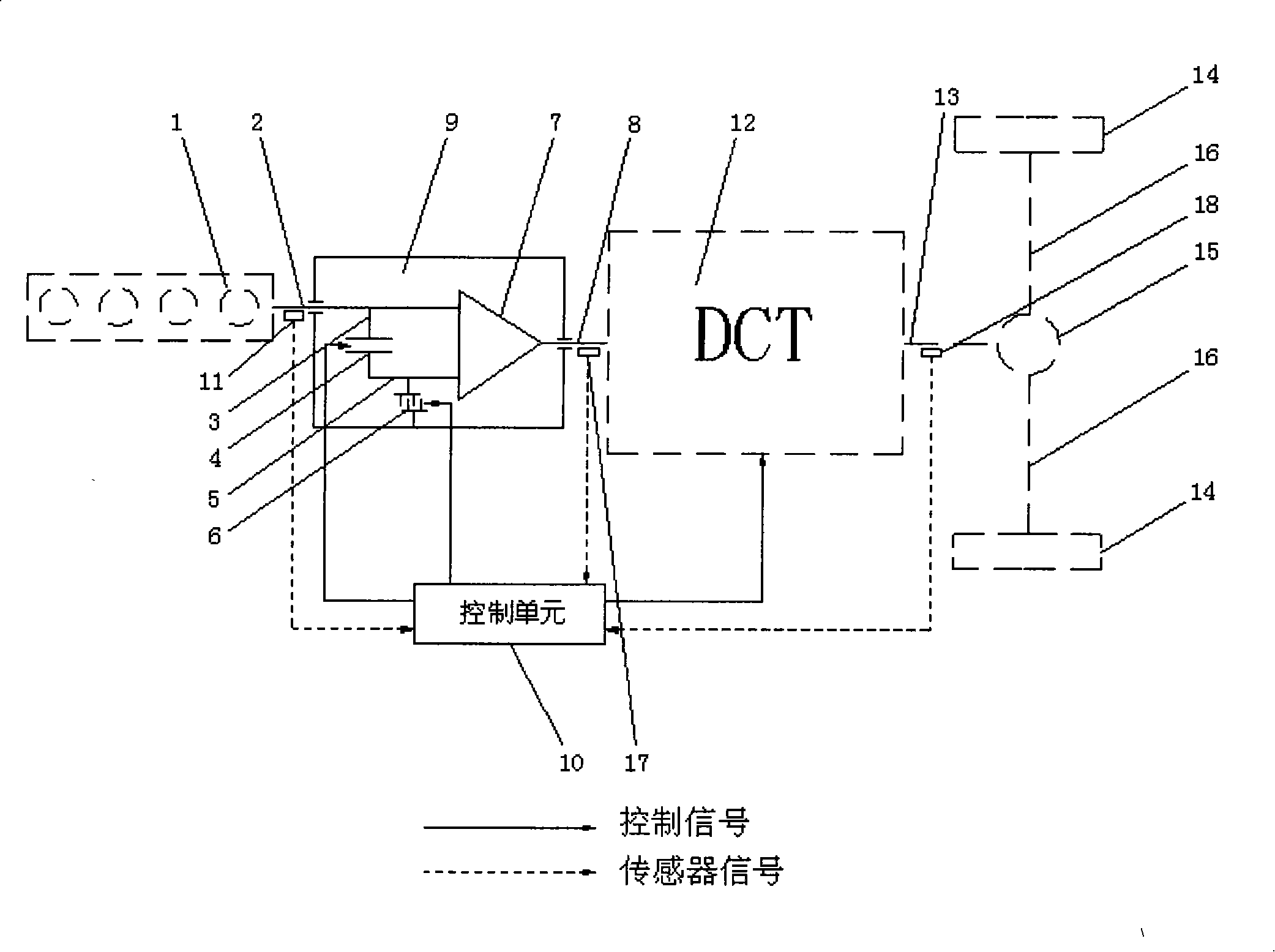

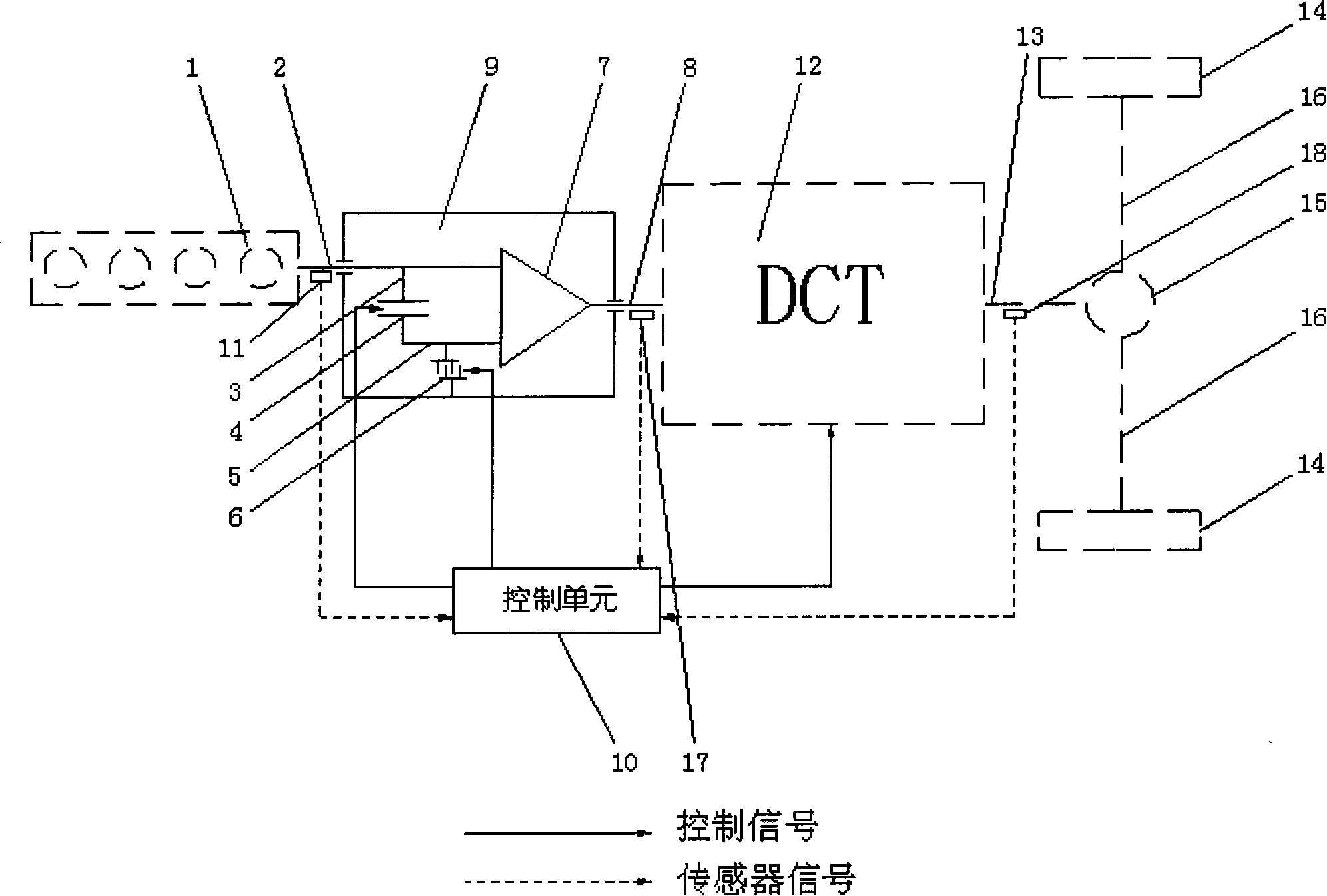

[0033] Embodiment 1: Transformation of the transmission of the dual-clutch automatic transmission car with five forward gears

[0034]As shown in Figure 2: a sub-convergence mechanism 9 is added between the engine and the DCT system of the dual-clutch automatic transmission car with five forward gears, including a single planetary planetary mechanism 7, a brake 6 and a clutch 4. Among them, the planet carrier of the planetary mechanism 7 is connected with the input shaft 8 of the DCT system, the sun gear of the planetary mechanism 7 is directly connected with the engine output shaft 2, the ring gear of the planetary mechanism 7 is connected with the clutch 4, and the clutch 4 is output through the transmission shaft 3 and the engine. The shaft 2 is connected, the brake 6 is connected with the ring gear of the planetary mechanism 7 through the transmission shaft 5, and is used to control the movement of the ring gear. The engine 1 is connected to the engine output shaft 2 . Th...

Embodiment 2

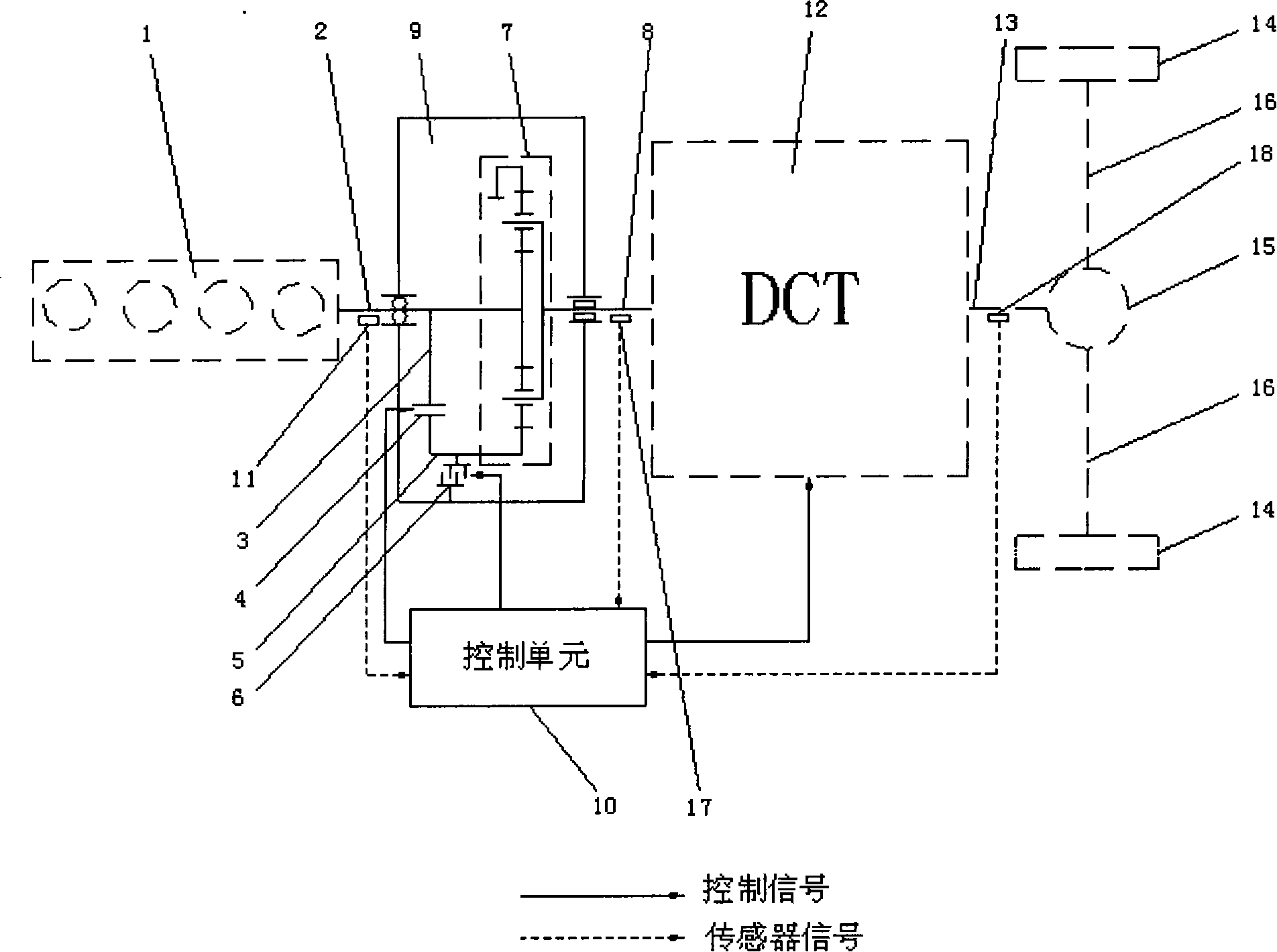

[0056] Embodiment 2: Another transformation of the transmission of the dual-clutch automatic transmission car with five forward gears

[0057] As shown in Figure 3: carry out another kind of form transformation on the speed changer of the double-clutch formula automatic transmission car of a five forward gears. Its structural arrangement is basically the same as that in Figure 2, except that the connection mode of the two input ends of the planetary mechanism is changed. The engine output shaft 2 is directly connected to the ring gear of the planetary mechanism 7, one end of the clutch 4 is connected to the sun gear, the other end is connected to the engine output shaft, and the brake 6 is connected to the sun gear to control the motion state of the sun gear; the planetary mechanism 7 The planet carrier is connected with the input shaft 8 of the DCT system. The working principle of this implementation example is basically the same as that of Embodiment 1, and will not be repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com