Quick-opening slow-closing water hammer relief valve

A discharge valve and water hammer technology, applied to valve details, safety valves, balance valves, etc., can solve problems such as pipeline network damage, and achieve the effect of avoiding secondary water hammer and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

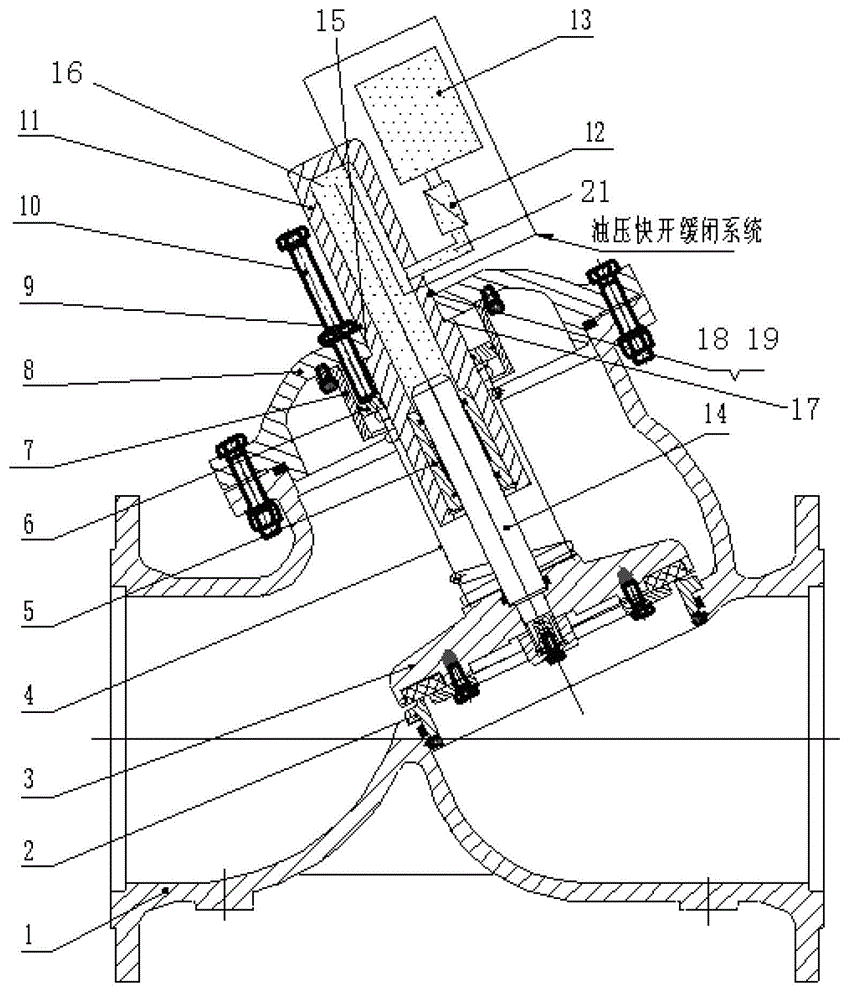

[0018] The opening of the sleeve 11 is in the valve body 1 , and the opening section of the inner hole 16 of the sleeve 11 is connected with the sleeve 5 .

[0019] The connection contact surface between the shaft sleeve 5 and the inner hole 16 of the sleeve 11 is sealed, and the sealing structure may be a sealing ring or a sealing structure of a sealing ring.

[0020] The valve stem 14 passes through the shaft sleeve 5 and extends into the inner hole 16 of the sleeve 11. A sealing structure is provided between the contact surface of the valve stem 14 and the shaft sleeve 5. For example, a sealing groove is provided on the inner hole wall of the shaft sleeve 5. A sealing ring is arranged in the sealing groove.

[0021] The inner wall of the valve cover 8 is connected with a guide sleeve 7, and the guide sleeve 7 is provided with a pressure plate 6, and the pre-tension spring 4 is arranged between the valve disc 3 and the pressure plate 6; the pressure plate 6 is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com