Light-splitting WDM device structure

A device structure and optical splitting technology, which is applied in the field of optical fiber communication, can solve the problems affecting the normal use of products, poor performance, long production cycle, etc., achieve good splitting effect, reduce manufacturing costs, and avoid the effects of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

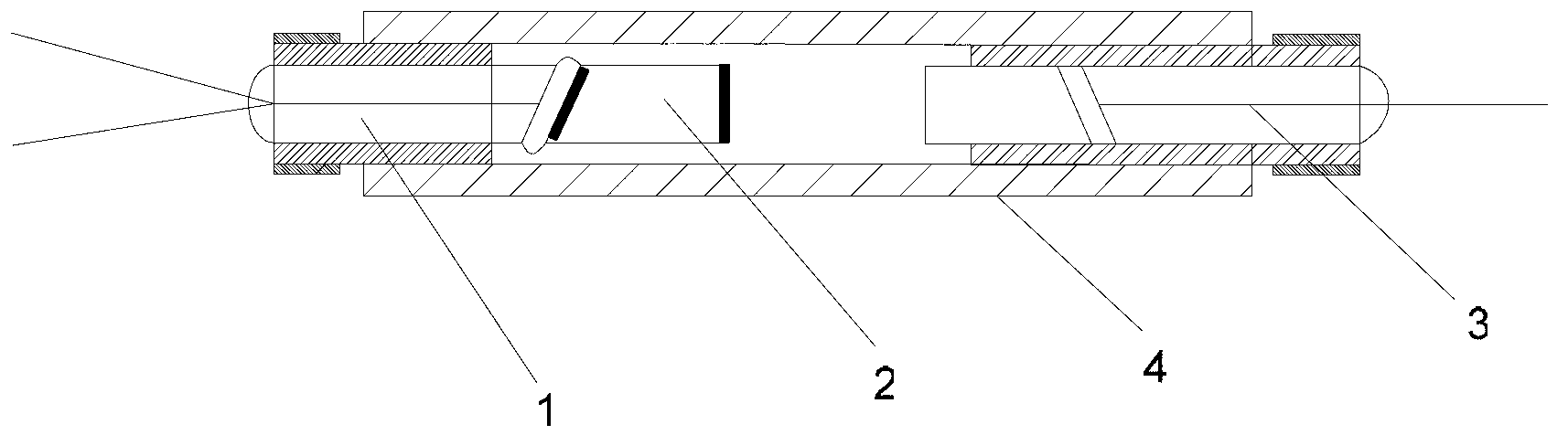

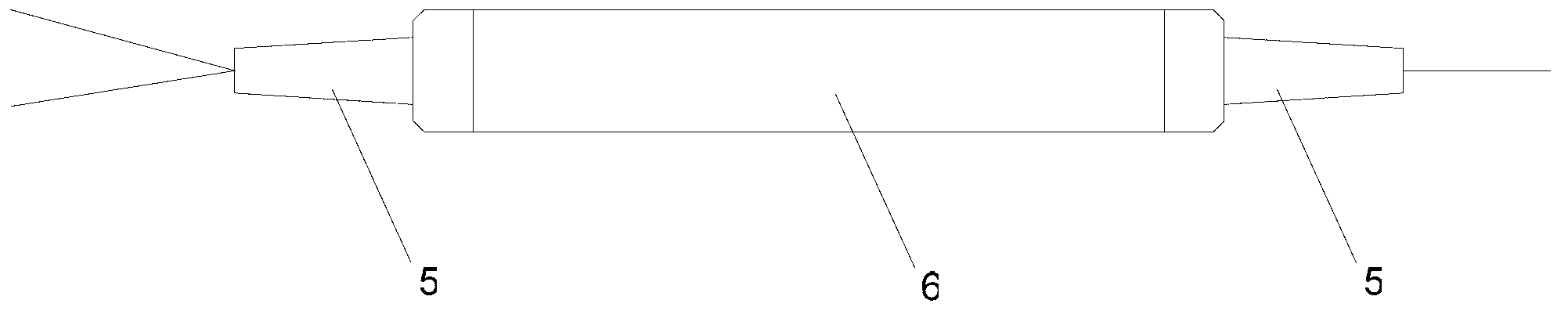

[0012] Such as figure 1 , figure 2 As shown, the present invention is composed of a double-fiber-ended fiber pigtail 1 , a lens 2 , a collimator 3 , a glass tube 4 , a sheath 5 and a steel tube 6 . The double-fiber-ended fiber pigtail 1 and the lens 2 are fixed together by UV-curable glue to form a reflective end. The two ends of the lens 2 are coated with a light-splitting film ( figure 1 The black parts at the left and right ends of the middle lens 2). Fix the reflection end, collimator 3 and glass tube 4 with UV curable glue. Then the above-mentioned whole structure is fixed in the steel pipe 6 with silica gel, and the sheath 5 is installed at both ends of the steel pipe 6, and the reflective end and the collimator respectively extend out of the optical fiber from the two sheaths to form the light-incoming end and the light-outgoing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com