Dummy pattern and method for forming same

A dummy pattern and pattern technology, applied in the field of dummy patterns and formation of dummy patterns, can solve problems such as insufficient stress resistance, decreased improvement effect of dummy pattern pattern density difference, limited improvement effect of dummy pattern pattern density difference, etc., to achieve uniform pattern density , to improve the effect of flattening results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

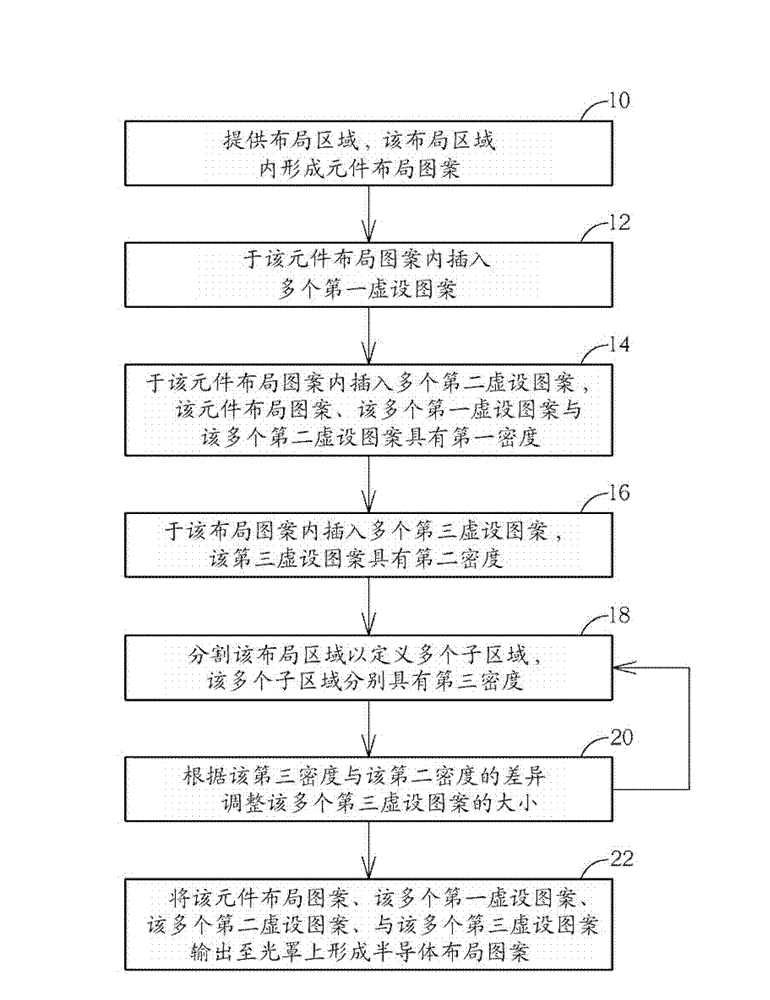

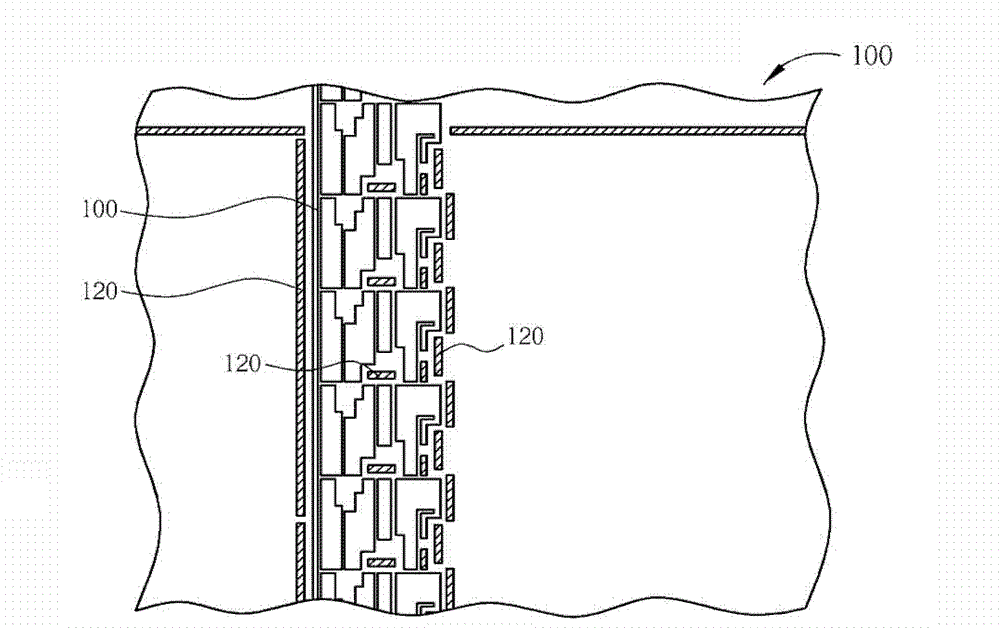

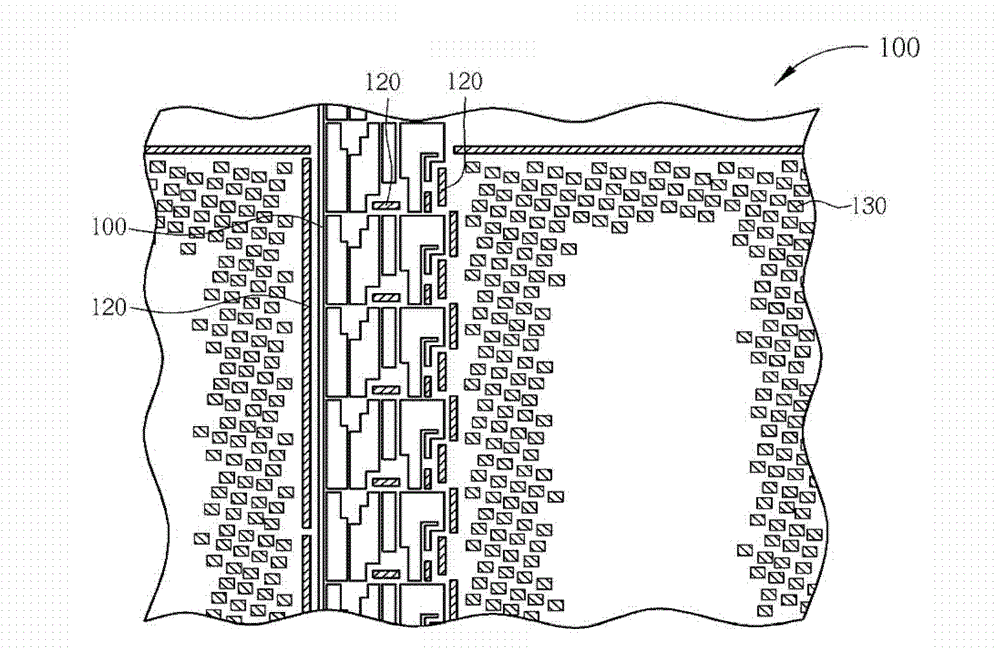

[0023] see Figure 1 to Figure 8 ,in figure 1 It is a flow chart of the first preferred embodiment of the method for forming dummy patterns provided by the present invention, Figure 2 to Figure 8 It is a schematic diagram of the first preferred embodiment of the method for forming dummy patterns provided by the present invention, Figure 5 then Figure 4 A partially enlarged schematic diagram. Such as figure 1 and figure 2 Shown, this preferred embodiment first carries out:

[0024] Step 10: providing a layout area in which a component layout pattern is formed.

[0025] Those skilled in the art should know that when making an integrated circuit, the original circuit layout pattern provided by the circuit design engineer is formed on the photomask, and then the pattern on the photomask is transferred to the target through the photolithography and etching process. Only on the film layer can the chip products that meet the circuit design function be manufactured. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com