Safety catalyzing valve for lead-acid storage battery

A technology of lead-acid batteries and catalytic valves, which is applied to battery pack components, secondary battery repair/maintenance, circuits, etc., to achieve the effects of reduced floating charge current, high use efficiency, and convenient assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

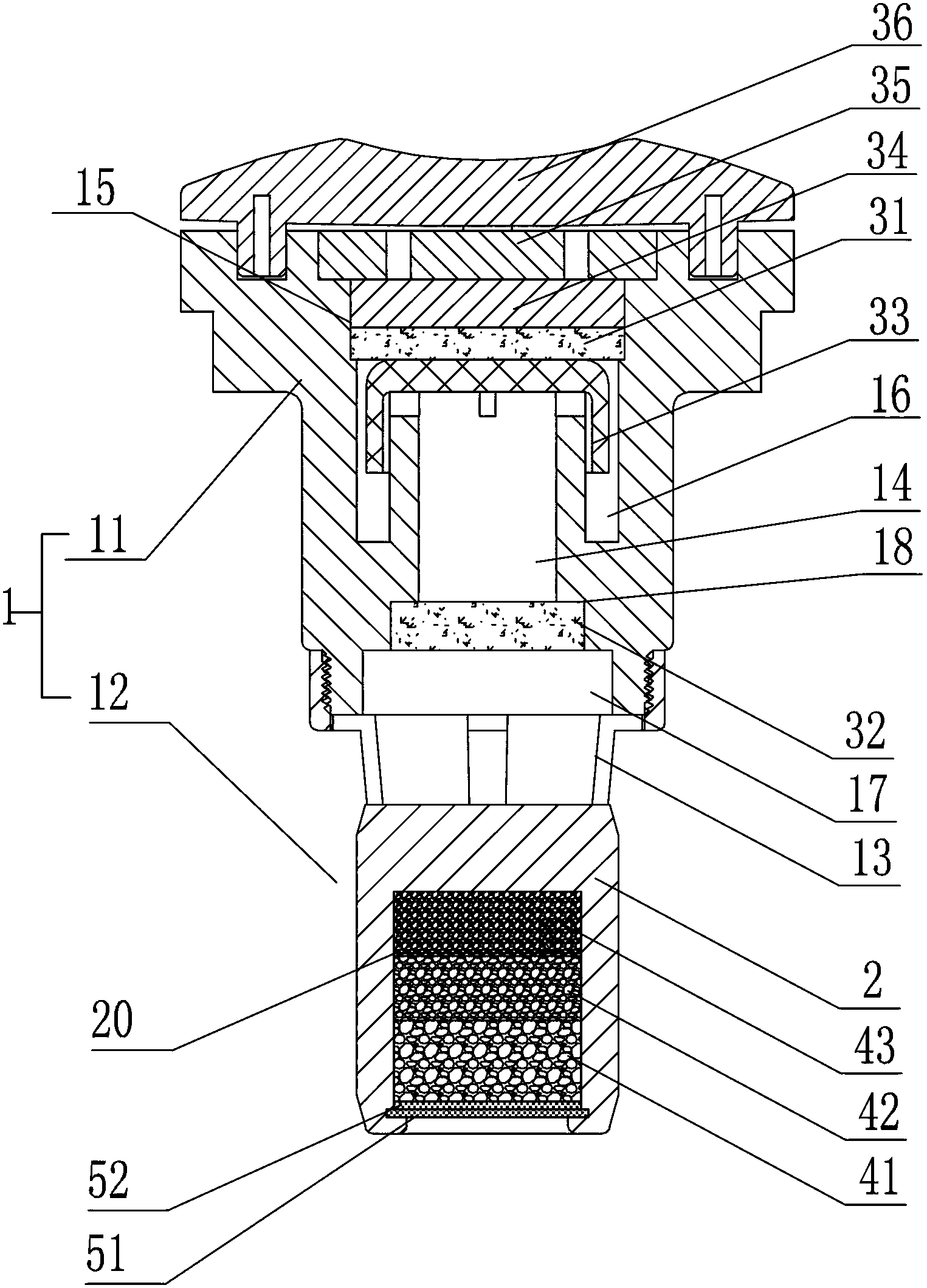

[0023] Refer to attached figure 1 . The present invention includes a valve body 1, the upper part 11 of the valve body is hollow, and the air pressure safety device of the lead-acid battery is installed in the upper part, so that when the pressure in the battery exceeds the safe value, the gas in the battery can be discharged in time . The lower part 12 of the valve body 1 is provided with a catalyst mounting seat 2, and a vent hole 13 communicating with the air pressure safety device is provided between the mounting seat 2 and the air pressure safety device; the mounting seat 2 is provided with a catalyst mounting hole 20 The catalyst that catalyzes the reaction of hydrogen and oxygen to produce water is installed in the installation hole 20, and a filter layer is arranged outside the catalyst; the valve body is installed on the battery cover.

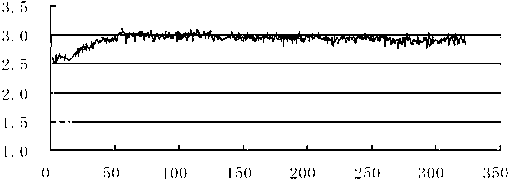

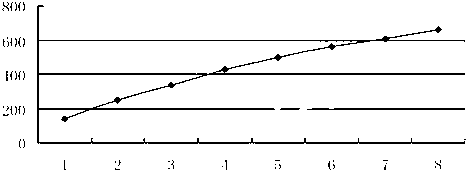

[0024] When the gas pressure inside the battery is lower than the safe value, the gas inside the battery can generate water throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com