Holding device for visually inspecting a tire

A tire, centering device technology, used in the manufacture of tires, the field of visual inspection of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

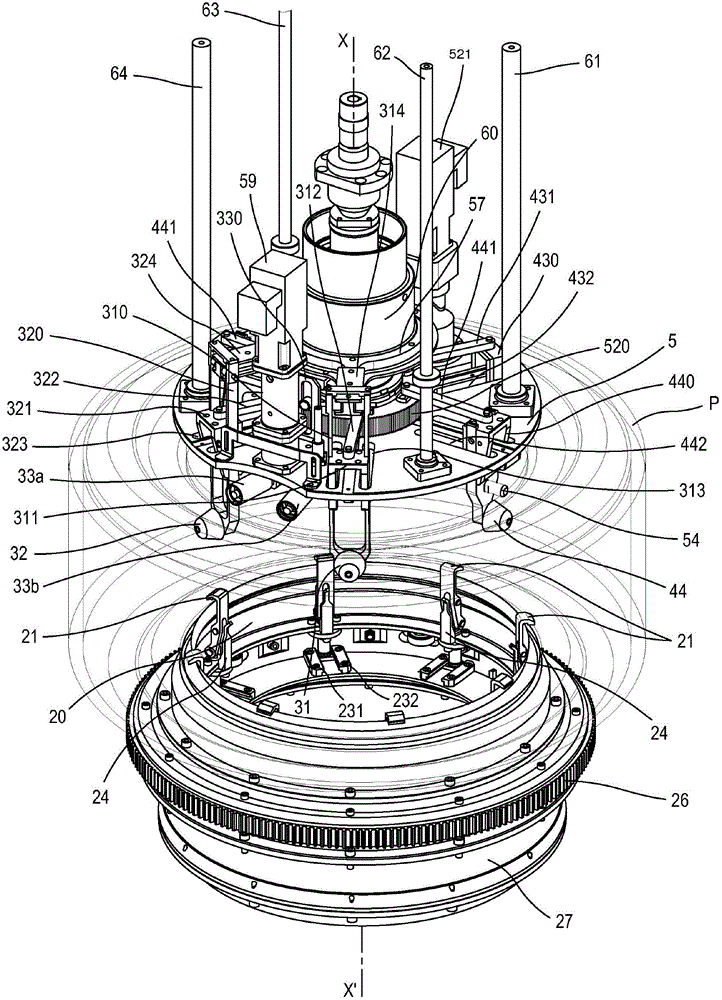

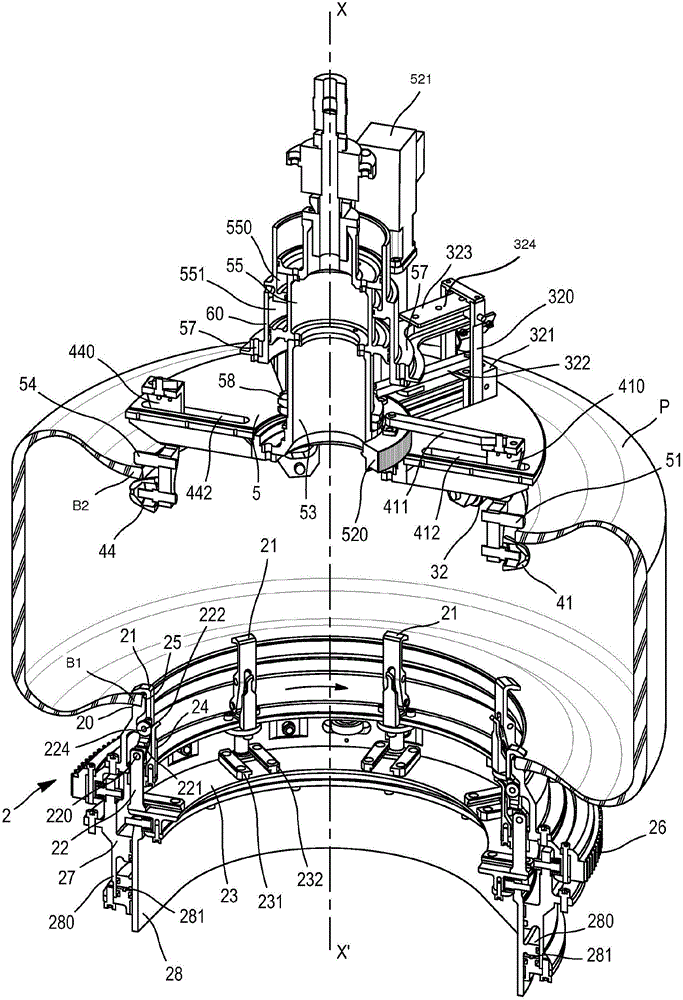

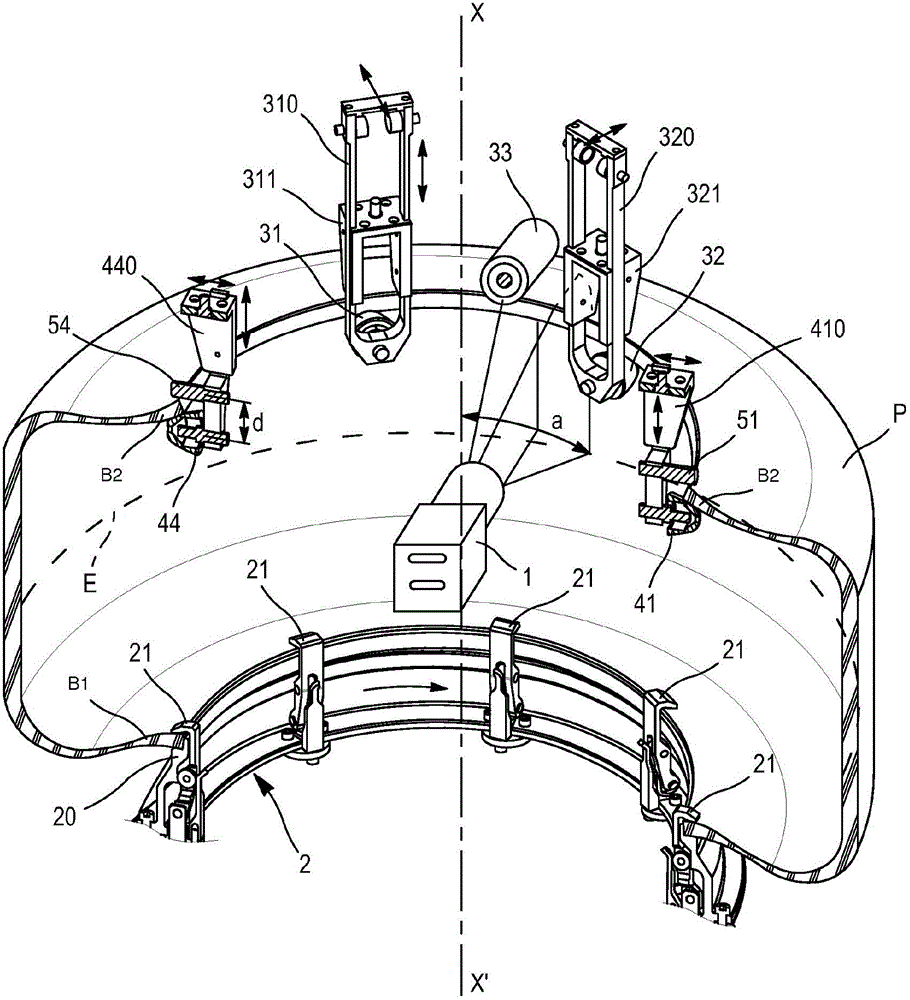

[0023] figure 1 and figure 2 The device in shows the main components forming the device according to the preferred embodiment of the invention.

[0024] In this illustration, a tire P with axis XX' is mounted on a centering device 2 . This centering device comprises a rim 20 shaped to accommodate the level of a seat 25 for receiving the first bead B1 of the tire P.

[0025] Distributed around the circumference of the rim 20 and pivoting around the pin 222 are a plurality of hooks 21 which hold the first bead B1 on the seat 25 around its entire circumference and in position. The rim 20 serves as a reference plate, itself mounted on a support ring 27 with axis XX' and connected by bearings to a frame (not shown) so that said ring 27 can pass through a motorized pinion (not shown) While rotating about the axis XX′, the motorized pinion meshes with a circular toothed rack 26 mounted on the radially outer periphery of the ring 27 . The axis of the rim is geometrically fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com