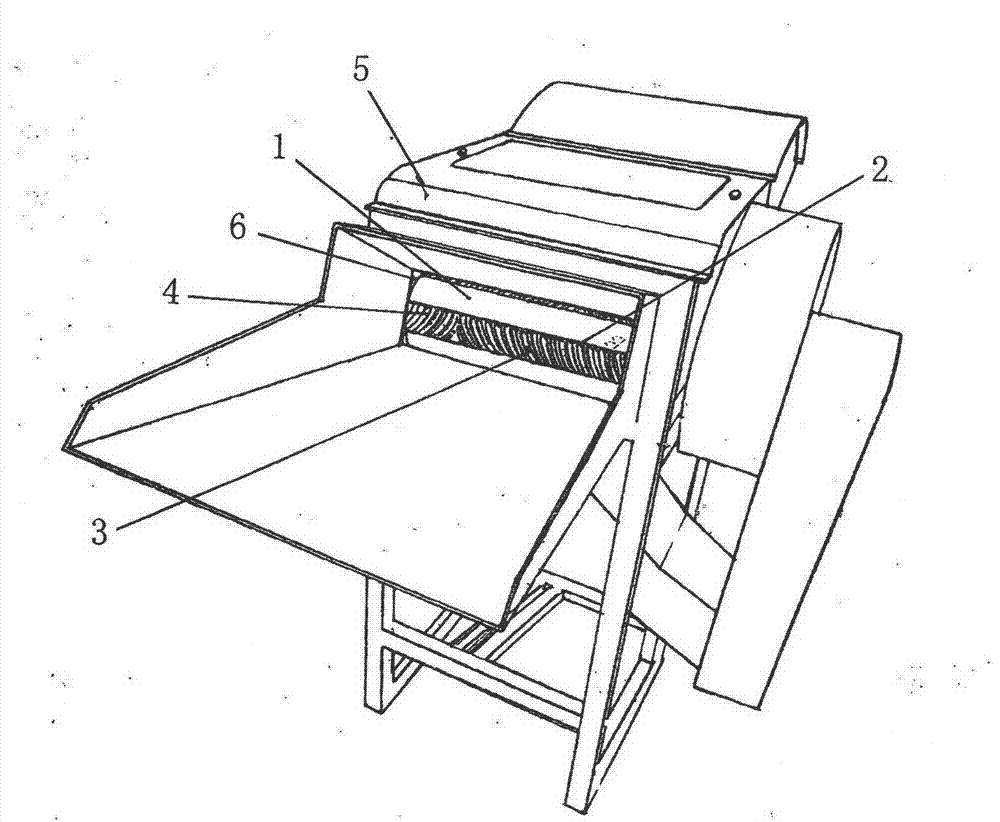

Threshing machine provided with positive and reverse spiral rack coiling roller

A helical rack and threshing machine technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as abnormal operation of threshing machines, affecting threshing efficiency, and stuck rolls, so as to reduce faults and improve threshing Efficiency, ensuring the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

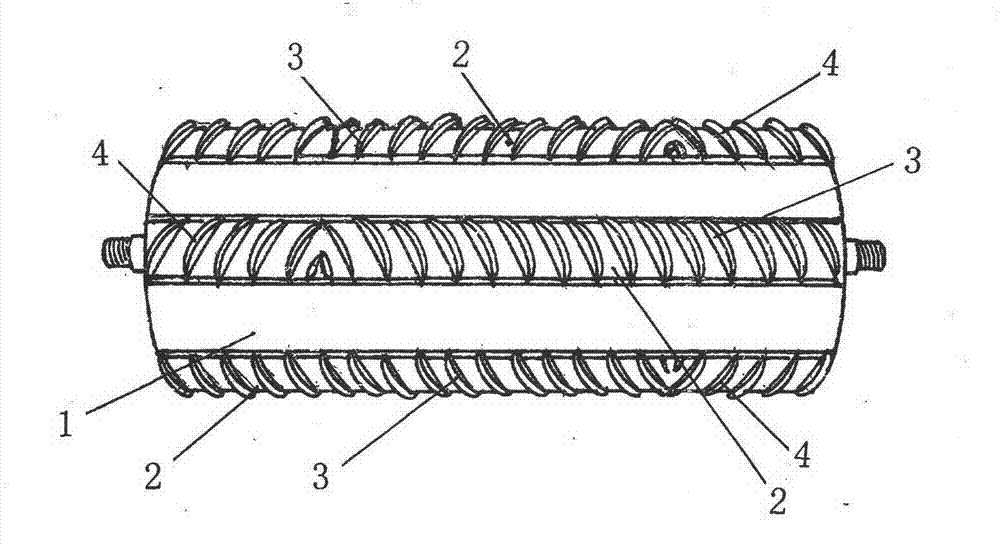

[0010] attached figure 1 , 2 As shown in the embodiment: several helical rack plates 2 are distributed on the installed winding roller 1 , and each helical rack plate 2 is provided with a forward-rotation rack 3 and a reverse-rotation rack 4 . The helical rack plates 2 of several forward-rotation racks 3 and reverse-rotation racks 4 are distributed on the winding roller 1 in an intersecting and staggered manner.

[0011] figure 2 In the embodiment: the forward-rotation rack 3 and the reverse-rotation rack 4 are set alternately and alternately.

[0012] In the running state: the forward spiral rack 3 in the spiral rack plate 2 on the winding roller 1 will roll in the material, and it will deviate to one side during the rolling process. The reverse spiral rack 4 will wind up the material in the middle, and the next spiral The bar 2 keeps up with the forward rotation rack 3 and continues to be drawn inward. When the deviation occurs again, the reverse rotation rack 4 will pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com