Purification method and equipment for filtering gas by using liquid medium

A technology of gas purification device and liquid phase medium, which is applied in the direction of chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., which can solve the problem of unsatisfactory purification effect and difficulty in achieving full contact mass transfer between filtered gas and liquid phase medium , high purification cost and other issues, to achieve the effect of improving the rising working condition, increasing the gas-liquid contact filtration area, and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by way of examples.

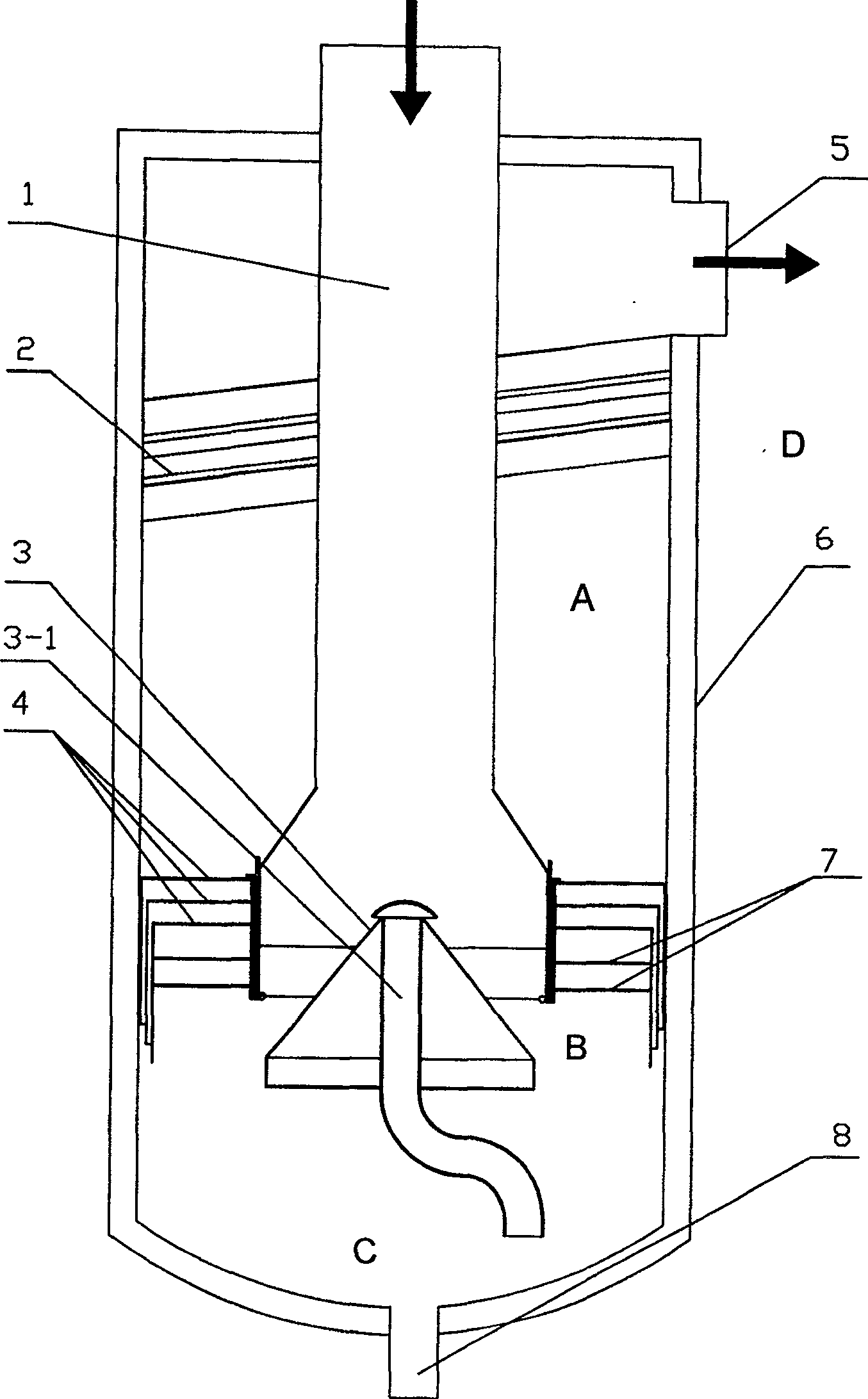

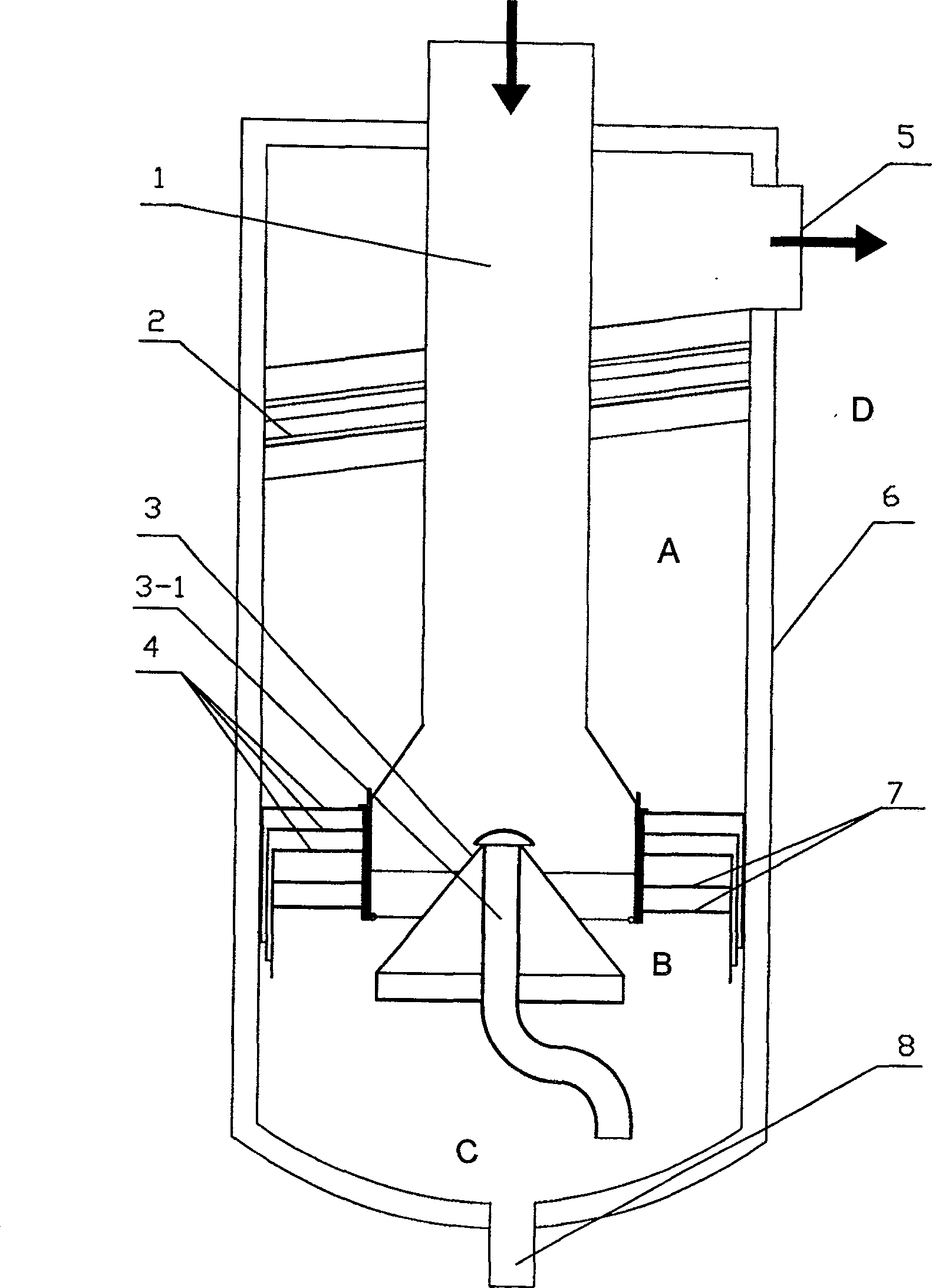

[0013] Such as figure 1 As shown in FIG. 3 , a method for purifying gas by filtering liquid-phase medium, there is a liquid-phase medium in the lower part of the outer cylindrical shell 6, and the liquid-phase medium will be continuously replenished. 1 There is a distance at the bottom, the filtered gas enters the outer shell 6 from the intake pipe 1, and impacts the liquid phase medium at the lower part of the outer shell 6 through the diversion cone 3, the liquid splashed from the bottom and the filtered gas are in the process of rising The mixed slurry passes through the refinement flow hood 4, so that the liquid medium forms a dynamic liquid medium filter layer on the refinement orifice plate 4-1, and at the same time, the filtered gas is divided into countless extremely fine gas columns. The column passes through the liquid medium filter layer on the refined orifice plate 4-1 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com