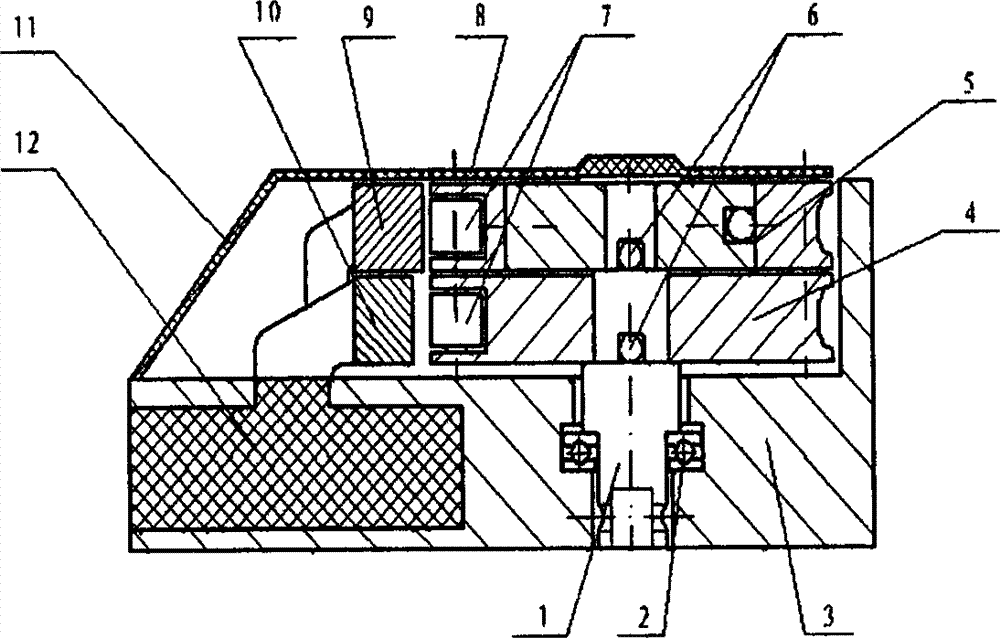

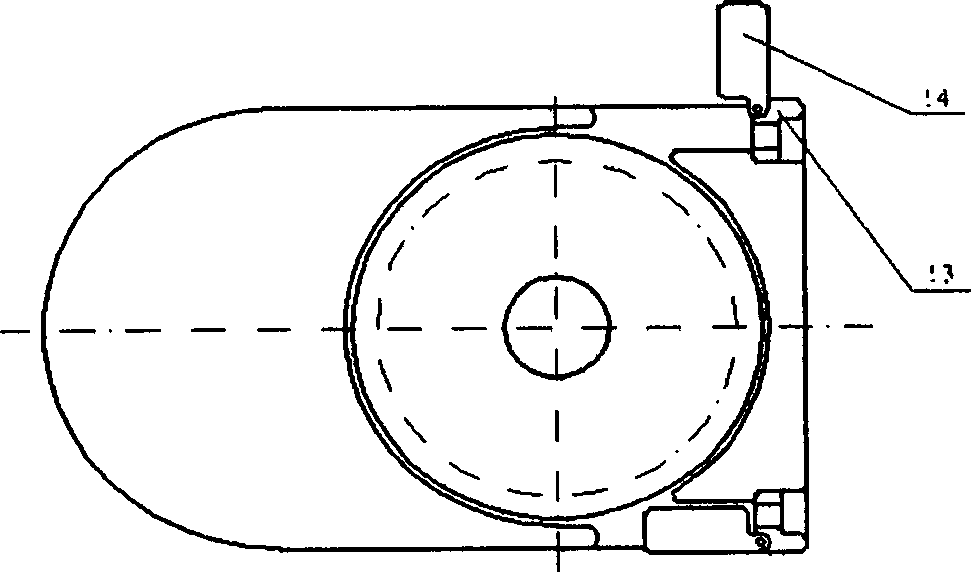

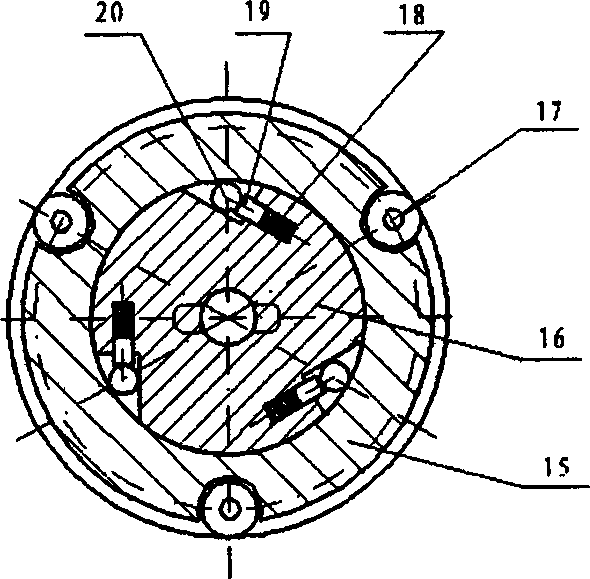

Composite peristaltic pump

A peristaltic pump and compound technology, applied in the field of peristaltic pump, to achieve the effect of stable operation, convenient installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ratchet in this embodiment can be a toothed ratchet or a ratchet, which has the same effect. The setting of the ratchet can be installed on the upper pump head or the lower pump head, and the other pump head can be selected from the conventional pump head.

[0027] The above description in conjunction with the embodiments of the present invention does not constitute any limitation on the protection scope of the present invention. Those skilled in the art can make various changes on the basis of the present invention, and these changes should be considered to fall within the scope of protection defined by the claims of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com