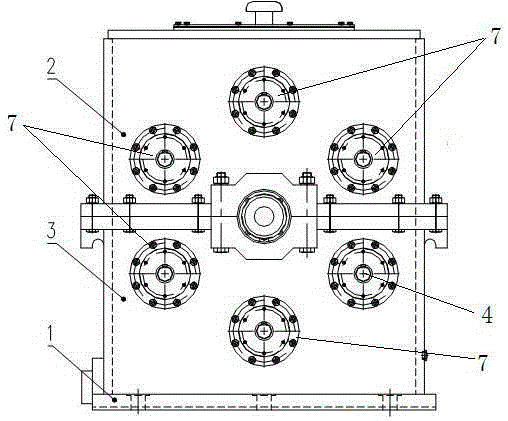

One-inlet and six-outlet integrated pipe rolling gearbox

A gear box and output gear technology, applied in metal rolling, metal rolling, drive devices for metal rolling mills, etc., can solve the problems of inconvenient adjustment, high cost, large equipment volume, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

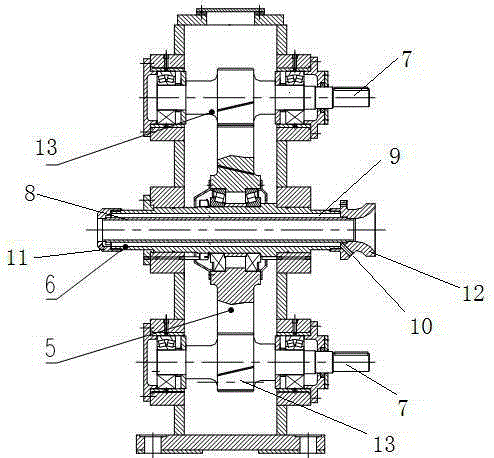

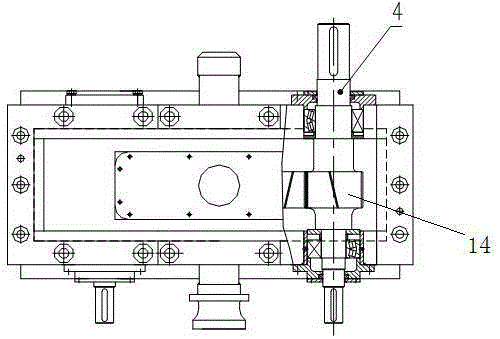

[0016] Such as Figure 1-3 shown.

[0017] A special gear box with one input and six outputs integrated for pipe rolling, which includes a box body 3 connected by a lower box body 1 and an upper box body 2, an idler 5 is installed in the center of the box body, and the idler wheel 5 is installed On the water jacket 6, the water jacket 6 is set on the mandrel 8, and the two ends of the water jacket 6 and the mandrel 8 are respectively equipped with a sealing spacer 12, and the mandrel 8 is preferably designed as a hollow structure, such as figure 2 As shown, the two ends of the water jacket 6 are fixedly supported on the box wall of the box, and a cooling water channel 9 is formed between the inner wall surface of the water jacket 6 and the outer surface of the mandrel 8, and the cooling water flows from one end of the cooling water channel 9 The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com