Particle sorting device

A sorting device and technology for granular bodies, which can be used in sorting and other directions, and can solve problems such as poor separation processing, insufficient air ejection speed or ejection volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

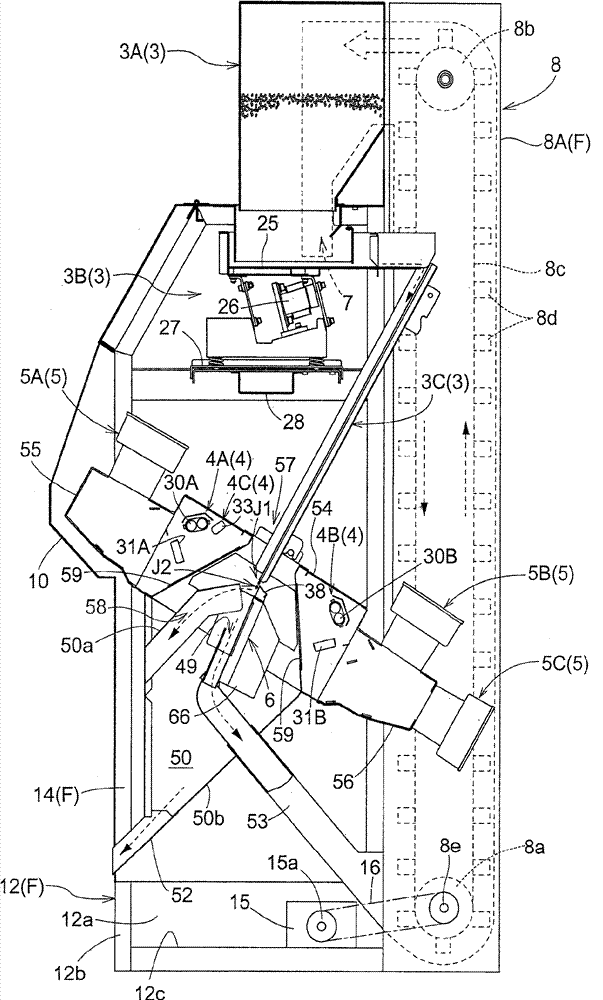

[0052] Hereinafter, based on the drawings, an embodiment of the granular body sorting apparatus according to the present invention is applied to the granular body group sorting that separates while guiding a group of rice grains such as brown rice or polished rice as an example of a granular body group. The situation in the device will be described.

[0053] like figure 1 and figure 2 As shown, there is provided a chute 3C in which the group of rice grains k is placed in a single layer in a flow state flowing down in a wide state, and guided toward the measurement target part J so that it passes through the measurement target part J. (An example of an inclined guide body) is configured so that the rice grain group k conveyed and supplied by the vibrating feeder 3B from the storage hopper 3A provided on the upper side of the chute 3C can flow upward on the upper surface of the chute 3C. Next, the unqualified grains whose light reflectance deviates from the appropriate range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com